Crossed Cylindrical Roller Slewing Bearing Precision Rigidity for Demanding Rotation

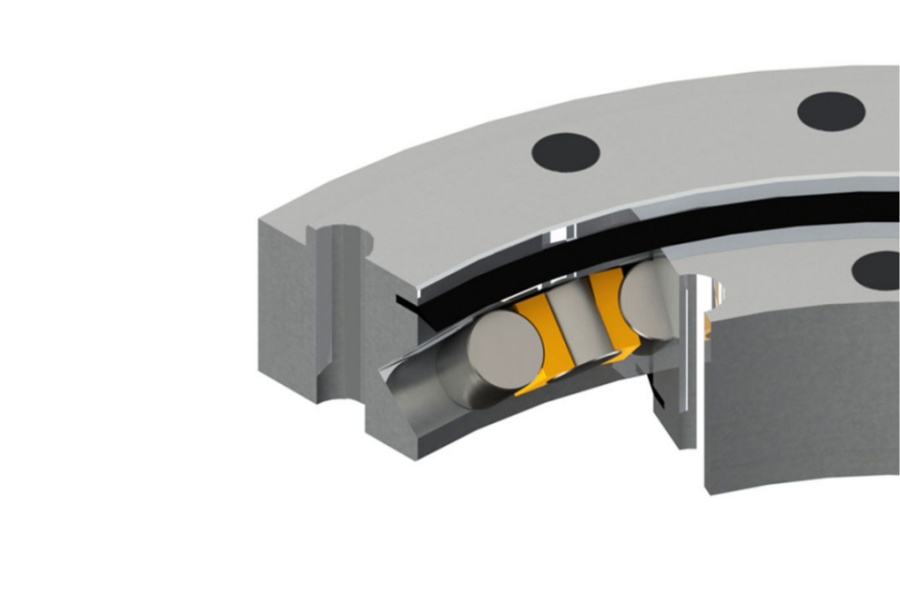

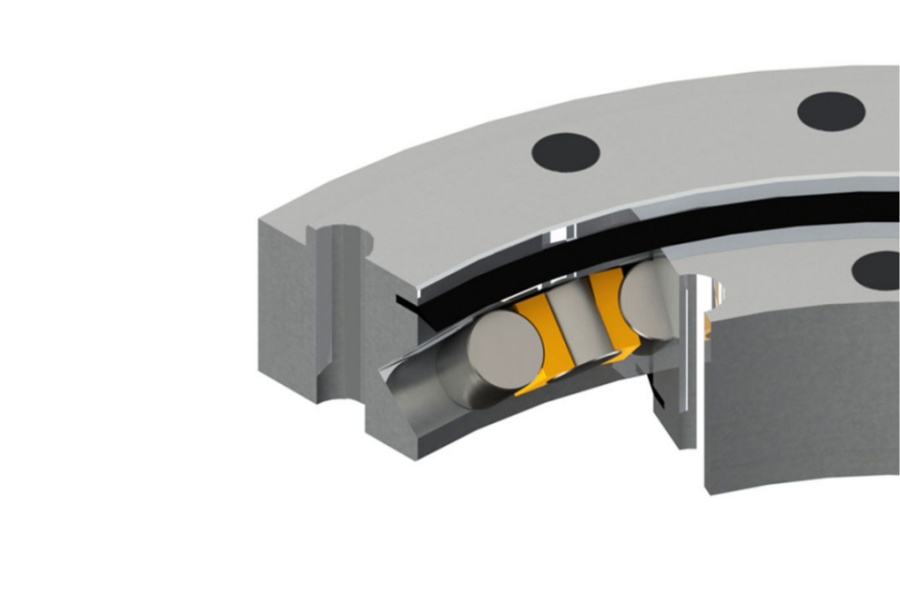

What is Crossed Cylindrical Roller Slewing Bearing

Crossed Cylindrical Roller Slewing Bearing is a specialized slewing ring characterized by its unique arrangement of cylindrical rollers. It comprises two rings (inner and outer) and a single row of cylindrical rollers oriented alternately at 90° angles to each other within the raceway. This cross-roller configuration forms a rigid orthogonal structure. Rollers are separated by precision spacers or a polymer cage, ensuring uniform spacing and preventing roller-to-roller contact. The raceways are hardened and ground to precise 90° V-grooves. Each roller makes simultaneous line contact with both raceway surfaces, enabling the bearing to transmit axial loads, radial loads, and tilting moments directly through surface contact rather than point contact. This fundamental design offers significantly higher rigidity and load density compared to ball-type slewing bearings of similar dimensions. Standard configurations include gearless, externally geared, and internally geared variants to accommodate different drive pinion requirements. Critical manufacturing tolerances ensure minimal runout and precise rotation for high-end applications.

Heat Treatment Processes in Slewing Bearing Manufacturing

Heat treatment is paramount for achieving the durability and performance required in crossed cylindrical roller slewing bearings. Key processes include:

Raceway Induction Hardening: Medium or high-frequency induction hardening selectively hardens the V-groove raceways to depths of 2.5-5mm, achieving surface hardness of HRC 55-60. Precise control ensures consistent hardened layer depth without compromising core toughness.

Tempering: Following hardening, tempering reduces internal stresses and brittleness, improving material ductility and fatigue resistance. Temperature and duration are tightly controlled.

Through Hardening (Optional): For smaller bearings or special requirements, through hardening (e.g., oil quenching) may be applied to achieve uniform hardness throughout the ring material.

Stress Relieving: Performed after rough machining and before finishing, this process minimizes residual stresses from forging, cutting, or welding, enhancing dimensional stability.

Carburizing (For Specific Grades): High-performance bearings may use carburizing on alloy steels to create a hard, wear-resistant surface layer while maintaining a tough, impact-resistant core.

Material selection (typically 50Mn, 42CrMo, or high-grade alloy steels) dictates the optimal heat treatment protocol. Post-heat treatment grinding achieves micron-level raceway accuracy and surface finish.

Energy Efficiency Ratio of Crossed Cylindrical Roller Slewing Bearing

The Crossed Cylindrical Roller Slewing Bearing exhibits moderate energy efficiency characteristics, primarily influenced by its design advantages and friction sources:

Low Friction Rolling: Precision-ground rollers and raceways minimize sliding friction, promoting smooth rolling motion. Optimized roller profile and spacing reduce parasitic drag.

Surface Contact Advantage: Line contact between rollers and raceways distributes loads over a larger area than ball bearings, potentially lowering Hertzian contact stresses and related friction under very high loads.

Rigidity Reduces System Losses: Exceptional rigidity minimizes elastic deformation under load, preventing misalignment-induced friction losses in the drive system (motors, gears).

Friction Considerations: Compared to ball slewing bearings, crossed roller designs typically exhibit higher starting and running torque due to greater contact area and seal drag. Careful lubrication selection (low-friction greases) and efficient sealing are crucial for mitigating this.

System-Level Efficiency: Their high load density often allows for more compact overall machinery designs, reducing the inertia that drive motors must overcome, thus improving system-level energy efficiency. While not inherently the lowest friction option, their stability and precision often lead to net energy savings in high-precision, high-load applications by preventing inefficient vibration or slippage.

Key Features of Crossed Cylindrical Roller Slewing Bearing

The Crossed Cylindrical Roller Slewing Bearing stands out due to several critical performance features:

Exceptional Rigidity: The orthogonal roller arrangement and surface contact create an extremely stiff structure, minimizing deflection under load for precise positioning.

High Load Capacity: Capable of handling very high axial, radial, and moment loads within a compact cross-section due to efficient load distribution via line contact.

Ultra-High Precision: Manufactured to tight geometrical tolerances (runout, flatness) and offering minimal axial/internal clearance, enabling sub-arcminute rotational accuracy.

Compact Design: Achieves high load ratings and rigidity in a significantly smaller envelope compared to equivalently rated ball slewing bearings or multi-row roller designs.

Smooth & Stable Operation: Precise roller spacing and grinding ensure consistent torque characteristics and smooth rotation without cogging.

Simplified Mounting: Often designed as a single, pre-assembled unit with mounting holes on both rings, simplifying integration and ensuring alignment integrity.

Minimal Elastic Deformation: Significantly lower elastic deformation under load compared to ball bearings, critical for machining and metrology applications.

Configuration Flexibility: Available in gearless, externally geared, or internally geared versions to suit diverse drive requirements.

High Durability: Hardened and ground raceways, combined with high-quality roller steel, provide excellent wear resistance and long service life under demanding conditions.

Applications of Crossed Cylindrical Roller Slewing Bearing

The unique combination of precision, rigidity, and compactness makes this bearing essential in demanding sectors:

Machine Tools & CNC Equipment: Rotary tables (4th/5th axis), indexing heads, precision machining centers, grinding machine spindles.

Industrial Robotics: Critical joints in articulated robots (waist, shoulder, wrist axes), especially in payload handling and precision assembly robots.

Semiconductor Manufacturing: Wafer handling robots, precision stages in lithography, inspection, and metrology equipment.

Medical & Laboratory Equipment: CT/MRI scanner gantries, radiation therapy equipment, high-precision rotary stages for imaging and diagnostics.

Optics & Defense: Precision turntables for telescopes, radar antenna pedestals, laser targeting systems, satellite communication apparatus.

Automated Assembly & Testing: High-precision indexing tables, vision inspection systems, pick-and-place units requiring micron-level repeatability.

Packaging Machinery: High-speed, precision filling and capping stations demanding rigidity and positional accuracy.

Aerospace: Testing rigs, antenna positioning systems, and simulator platforms.

Material Handling: Precision rotary transfer lines and automated storage/retrieval system (AS/RS) positioning modules.

Factors Influencing Crossed Cylindrical Roller Slewing Bearing Price

The cost of these precision bearings is driven by multiple technical and commercial factors:

Size & Dimensions: Larger diameters, widths, and roller sizes exponentially increase material costs and complex machining/grinding time.

Precision Grade: Ultra-high precision bearings (P4, P2 levels per ABEC or ISO standards) with sub-micron tolerances and runout specifications demand significantly more stringent manufacturing and inspection, drastically increasing cost.

Load Capacity & Rating: Bearings engineered for higher dynamic and static load ratings require larger rollers, wider raceways, deeper hardening, and potentially special material grades.

Material Selection: Standard bearing steel (e.g., 100Cr6/52100) is baseline. Specialty steels (e.g., high-purity vacuum degassed steels) for enhanced life or corrosion-resistant grades (e.g., stainless AISI 440C) add substantial cost.

Gear Options & Complexity: Adding precision ground external or internal gears significantly increases machining complexity and cost compared to gearless versions. Gear quality (e.g., DIN class) impacts price.

Heat Treatment & Hardening Depth: Deeper case hardening or specialized processes (like carburizing) add cost. Achieving uniform hardness on complex V-grooves is challenging.

Sealing & Lubrication: High-performance seals (multi-lip, low-friction materials like PTFE) and special greases (cleanroom compatible, wide temperature range) increase cost.

Customization: Non-standard bore/OD dimensions, special bolt hole patterns, custom preload settings, unique surface coatings (e.g., DLC, anti-corrosion), or modified sealing solutions incur engineering and setup charges.

Quantity & Production Run: Low-volume or prototype batches have high unit costs due to setup amortization. High-volume production enables economies of scale.

Quality Assurance & Certification: Costs rise with requirements for full material traceability (mill certs), extended fatigue testing, destructive analysis, or specific industry certifications (e.g., ISO 9001, AS9100, medical device standards).

Origin & Brand: Manufacturing location (labor, overhead costs) and brand reputation/premium influence pricing.

Supplier of is Crossed Cylindrical Roller Slewing Bearing

LYRADRIVE is a specialized manufacturer of high-performance slewing solutions, offering an extensive range of precision Crossed Cylindrical Roller Slewing Bearings. Their portfolio includes standard gearless, externally geared, and internally geared configurations designed for demanding applications requiring exceptional rigidity and accuracy. LYRADRIVE utilizes advanced manufacturing techniques, stringent quality control processes, and rigorous material selection to ensure reliable performance in sectors like machine tools, robotics, and medical equipment. They provide both catalog solutions and engineered-to-order bearings, supporting customers with technical expertise for optimal integration and longevity. LYRADRIVE focuses on delivering robust rotational components backed by engineering support.