Analysis of Causes and Solutions for Problems in Slewing Bearing Operation

What is Slewing Bearing

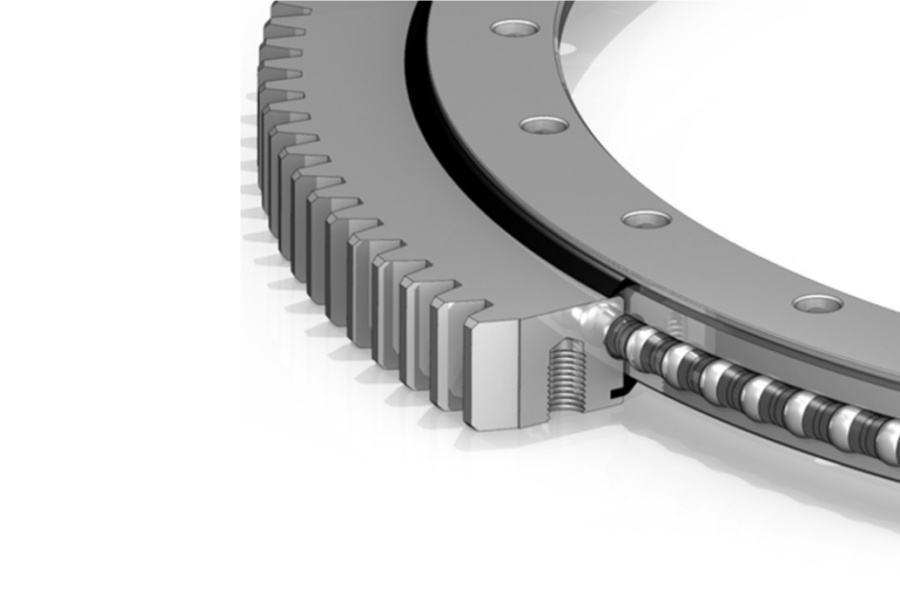

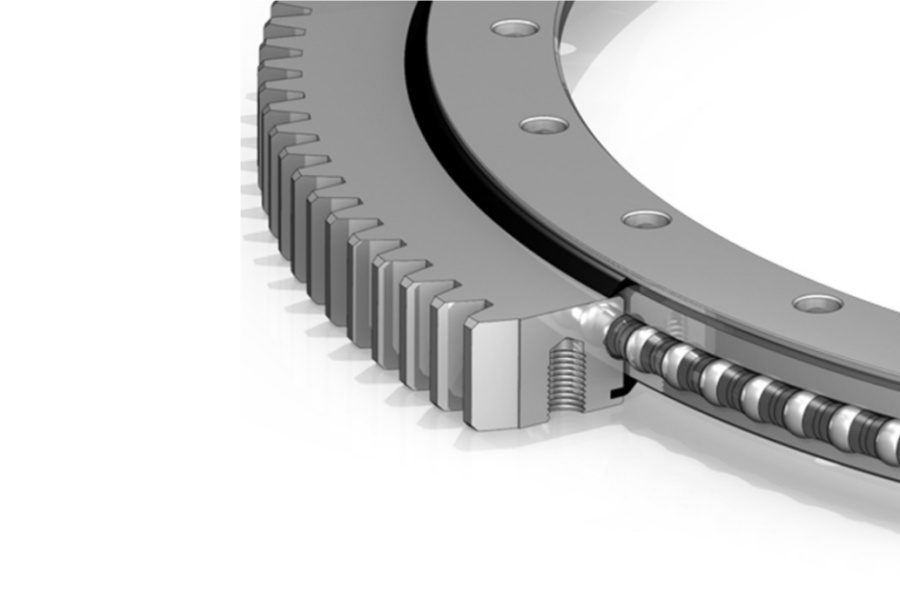

Slewing Bearing is a large-scale rotational rolling-element bearing that is fundamental to modern industrial machinery, uniquely engineered to support exceptionally heavy combined loads—axial, radial, and moment loads—while facilitating smooth and controlled 360-degree rotation between two structures. Unlike conventional bearings that are merely components within a system, slewing rings are integral structural elements that form a direct and critical connection between a machine's upper superstructure, such as a crane boom or excavator house, and its lower chassis or base. Their construction is characterized by a robust, compact design featuring two solid rings with precision-machined raceways that accommodate rolling elements, which can be balls or rollers, typically spaced and guided by separators or cages to ensure even load distribution and prevent friction. A quintessential feature of many slewing bearings is the inclusion of an integrated gear, meticulously machined onto either the inner or outer ring, which meshes with a pinion to create a highly efficient and compact drive system for powered rotational movement. Furthermore, advanced sealing systems are paramount, acting as a primary defense mechanism to protect the internal rolling contact surfaces and gear teeth from invasive contaminants like dirt, abrasive dust, and moisture, thereby ensuring long-term reliability and consistent performance. This unparalleled versatility in managing complex load scenarios within a single, self-contained unit makes them indispensable components across a vast spectrum of industries, from heavy construction and renewable energy to advanced medical imaging and defense systems.

Analysis of Causes and Solutions for Problems in Slewing Bearing Operation

Slewing bearing failure is rarely a sudden event but is typically the culmination of one or more underlying issues that gradually degrade performance until catastrophic malfunction occurs. Understanding the root causes of these problems and implementing proactive solutions is critical for maximizing equipment uptime, ensuring safety, and controlling maintenance costs. The most prevalent issues can be categorized into several key areas, each with distinct causes and corrective measures.

The single most common cause of premature slewing bearing failure is inadequate or improper lubrication. This encompasses not only insufficient grease but also the use of incorrect grease type, grease contamination, and degraded grease that has lost its properties. Operating a bearing with inadequate lubrication leads to immediate metal-on-metal contact, resulting in accelerated wear, scoring of the raceways, excessive heat generation, and ultimately, bearing seizure. The solution is a disciplined, condition-based lubrication regimen. This involves using the manufacturer-recommended type of grease (e.g., Lithium-based EP2 for standard applications, synthetic or specialty greases for extreme temperatures), following the prescribed re-lubrication intervals (typically every 400 operating hours, but more frequently in harsh conditions), and purging old grease until fresh grease emerges from the seal lips to ensure the raceways are fully packed. Contamination prevention is equally critical; damaged seals must be replaced immediately, and lubrication equipment must be kept clean to prevent introducing abrasive particles during maintenance.

Improper installation is another major contributor to early failure. This includes mounting the bearing on an uneven or insufficiently rigid foundation, using improperly sized or misplaced bolts, applying incorrect bolt tightening sequences and torque values, and failing to achieve proper gear meshing between the pinion and the internal gear. An uneven mounting surface induces internal preloads and stresses, causing high spots that lead to brinelling, increased rotational torque, and premature fatigue. The solution is strict adherence to the manufacturer's installation manual. This requires preparing a machined, flat, and rigid mounting surface, using high-strength fasteners of the correct grade and size, following the cross-pattern torque sequence with a calibrated torque wrench to achieve the specified preload, and carefully adjusting the pinion gear backlash to the recommended specification. Failure to do so will inevitably lead to misalignment, abnormal loads, and a significantly shortened bearing life.

Overloading and operational abuse are frequent causes of catastrophic failure. This involves consistently exceeding the bearing's dynamic load rating, subjecting it to severe shock loads beyond its static capacity, or exceeding the maximum allowable rotational speed. Such practices cause plastic deformation of the raceways (brinelling), accelerate surface fatigue, and can lead to ring fracture or gear tooth breakage. The solution is operational discipline and correct sizing. The bearing must be selected with adequate safety factors for the actual application loads, including dynamic and shock loads. Operators must be trained to avoid abusive practices, such as swinging heavy loads at high speeds or using the equipment for unintended purposes like impact hammering. For applications with unpredictable shock loads, bearings with higher static capacity ratings or specifically designed robustness should be selected.

Environmental factors and seal failure pose a constant threat. Exposure to abrasive dust, water, seawater, chemicals, or extreme temperatures can rapidly degrade the bearing. Once seals are compromised, contaminants ingress, washing away lubricant and forming a grinding paste that accelerates wear and causes corrosion. The solution is selecting the right bearing for the environment and vigilant maintenance. This includes specifying bearings with multi-lip seals, stainless steel components, or special coatings like zinc-nickel for corrosive environments. For extremely dusty or wet conditions, additional external protective measures like scrapers or bellows may be necessary. Regular inspection of seals for cuts, cracks, or deformation is essential, with immediate replacement of any damaged seals to maintain the integrity of the bearing's internal environment. By systematically addressing these root causes through proper maintenance, installation, operation, and selection, the service life of a slewing bearing can be maximized, ensuring safe and reliable machine operation.

Characteristics of Slewing Bearing

Slewing bearings are defined by a unique set of engineering characteristics that fundamentally differentiate them from standard bearings and qualify them for their role as both a rotational component and a structural element. Their most critical characteristic is their unparalleled capacity to handle complex combined loads. A single, compact slewing bearing is specifically designed to simultaneously support massive axial forces (parallel to the axis of rotation), radial forces (perpendicular to the axis), and tilting moment loads (which create a overturning force), a capability that would otherwise require a complex and space-consuming system of multiple conventional bearings. This multifunctional load-handling ability is the cornerstone of their design, simplifying machine architecture, reducing the number of parts, and enhancing overall structural integrity and stiffness.

Another defining feature is their integrated and customizable design philosophy. Beyond merely providing raceways for rolling elements, slewing bearings are engineered as complete system solutions. The most common integration is a precision-machined gear, either on the inner or outer ring, which transforms the bearing into a compact and highly efficient rotational drive mechanism. They also feature mounting holes drilled and tapped directly into the rings, facilitating direct bolting to adjacent structures and eliminating the need for additional, costly housings. Advanced sealing systems are integral, typically consisting of multi-lip elastomeric seals or labyrinth paths to provide maximum protection for the internal components against harsh environmental contaminants like dirt, mud, and water. Furthermore, they are pre-fitted with lubrication fittings (grease nipples) and often internal channels to ensure the rolling elements and gear teeth are consistently and adequately lubricated throughout their long service life.

Durability and longevity are engineered into their core from the material level upwards. Manufactured from high-quality, high-carbon chromium steel (e.g., 42CrMo4, 50Mn) and subjected to rigorous heat treatment processes like induction or flame hardening, the raceways and gear teeth achieve a extremely hard, wear-resistant surface while retaining a tough, shock-absorbing core. This ensures exceptional resistance to fatigue, pitting, and brinelling, even under heavy, cyclical, and shock loading conditions. Furthermore, their design allows for immense versatility in size and customization. Slewing bearings are produced in a vast range of diameters, from a few hundred millimeters to over ten meters, and can be customized with specific seal types, gear geometries, hardening patterns, and hole configurations to meet the exact requirements of virtually any application, making them a highly adaptable and critical engineering solution.

Applications of Slewing Bearing

The application of slewing bearings is virtually ubiquitous in any heavy-duty machinery that requires robust, controlled rotation under significant load. They are the fundamental enablers of movement in heavy industries, forming the rotational heart of countless machines. In the construction, mining, and agricultural sectors, they are the core component that allows an excavator's upper house to rotate 360 degrees, enables the boom of a mobile crane to lift and slew, and forms the base for crawler cranes. They are also essential in tunnel boring machines, concrete pump trucks, and heavy-duty tractors.

The renewable energy sector is a major and rapidly growing application field. Slewing bearings are absolutely critical in the yaw systems of wind turbines, responsible for accurately positioning the massive nacelle to face the wind, and in the pitch systems, adjusting the angle of the blades for optimal power generation and storm protection. In solar power generation, they are the key component in solar tracking systems, allowing vast arrays of photovoltaic panels to precisely follow the sun's path across the sky, significantly increasing energy yield.

In industrial material handling, they are essential for port efficiency and automation, operating in the massive stacking and reclaiming machines at shipping terminals and in the deck cranes that load and unload container ships. They are found in rotary conveyors, the turntables of forklifts, and automated warehousing systems. The defense and aerospace sectors utilize high-precision, ultra-reliable slewing rings in radar and surveillance antennae for accurate positioning and tracking, in tank turrets for weapon aiming and stability, and in missile launch system platforms.

The medical industry relies on specially designed, high-precision, and often cleanroom-compatible slewing bearings for advanced diagnostic equipment such as CT scanners and MRI machines, where they enable the smooth, quiet, and precise rotation of heavy imaging gantries around the patient. Finally, they are found in a multitude of other industrial machines, including robotic welders and assemblers, indexing tables on CNC machining centers, packaging equipment, and even in large-scale industrial rotators and positioners. This immense diversity underscores their role as a critical, unsung hero in global industry and technology.

Factors Influencing the Price of Slewing Bearing

The price of a slewing bearing is not a simple figure but is determined by a complex interplay of technical specifications, material choices, manufacturing processes, and commercial factors. Understanding these variables is crucial for making informed procurement decisions and evaluating the true value of a component. The single largest cost driver is often the raw material. The type, grade, and quantity of steel required have a direct and significant impact on the final price. Standard carbon chromium steel (e.g., 42CrMo4) is common, but applications requiring enhanced corrosion resistance, such as in marine environments, necessitate the use of stainless steel (e.g., SS304, SS440C), which will see a substantial price increase due to the more expensive base material and its more difficult machining and heat treatment properties. The physical dimensions—primarily the diameter, but also the width and cross-sectional height—directly scale the material cost and weight.

The complexity of the manufacturing process and the level of customization are another major determinant of cost. A standard, off-the-shelf bearing will be far less expensive than a fully customized one. Customizations such as integrated gearing (including the gear type, module, precision grade, and its location), special sealing arrangements (multiple layers, specific elastomer compounds for extreme temperatures), unique mounting hole patterns, and special surface coatings (e.g., zinc plating, black oxide) all add significant steps, specialized tooling, and time to the production process, increasing the manufacturing overhead.

The required precision tolerance grade and performance specifications dramatically influence the price. A bearing manufactured to standard industrial tolerances for a digger arm is cost-effective. However, one produced to ultra-precise, micron-level tolerances for a medical CT scanner or a military radar, requiring 100% non-destructive testing (NDT) like magnetic particle or ultrasonic inspection, full material traceability with 3.1 mill certificates, and extended fatigue life testing, will command a premium price due to the extensive additional labor, slower production pace, and advanced quality assurance protocols involved.

The quantity ordered is a fundamental economic factor governed by economies of scale. Large volume production runs allow the manufacturer to amortize fixed costs (like custom tooling setup, CNC programming, and first-article inspection) over many units, drastically reducing the price per bearing. A one-off prototype or a small batch order will have a significantly higher unit cost to cover these fixed expenses. Finally, external supply chain factors like global fluctuations in steel prices, international logistics and shipping costs, and import/export tariffs and duties can also cause fluctuations in the final price offered to the customer, making the total landed cost a key consideration.

Supplier of Slewing Bearing

For engineers and procurement specialists seeking a reliable source for high-performance slewing bearings, LYRADRIVE stands as a manufacturer with deep expertise in the engineering and production of these critical components. The company's technical support extends beyond supply to providing comprehensive guidance on proper installation procedures, maintenance schedules, and failure analysis, helping customers prevent common operational problems and maximize the service life of their equipment. This focus on application engineering and proactive support is backed by a rigorous quality management system that governs every stage of production, ensuring every component that leaves its facility meets stringent standards for durability, precision, and operational reliability. By offering this combination of advanced manufacturing capabilities, engineering-led problem-solving, and a commitment to delivering long-term value, LYRADRIVE has established itself as a trusted partner for a global clientele across diverse industries such as construction, renewable energy, material handling, and specialized industrial machinery.