Why Slew Drive Operation Generates Noise

What is Slew Drive

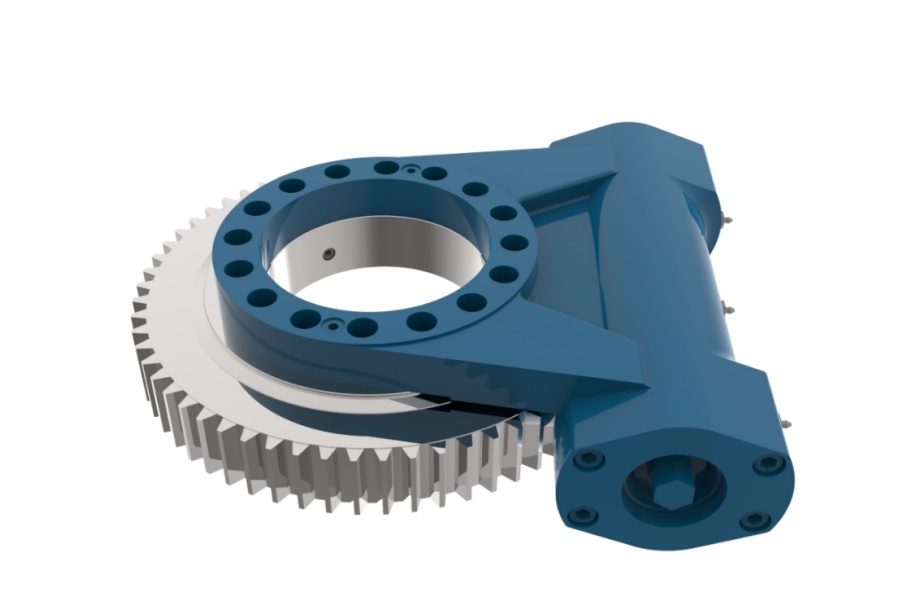

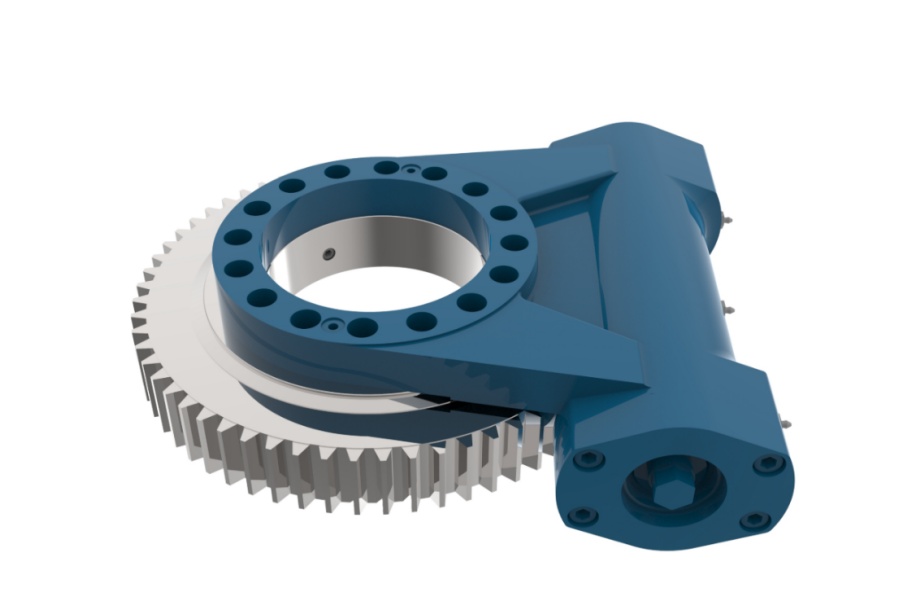

Slew Drive is a fully integrated mechanical actuator system designed to provide controlled, high-torque rotational movement about a single axis. It represents a complete fusion of a robust drive motor (typically hydraulic or electric), a high-ratio speed reducer—most commonly a worm gearbox but also planetary or bevel gear systems—and a large-diameter slewing ring bearing that often features an integrated gear. This integrated design distinguishes it from systems where these components are sourced and assembled separately on the final machine. The primary function of a slew drive is to efficiently transform the high-speed, low-torque output of its input motor into a slow-speed, high-torque rotational output, enabling it to manage immense loads with precise control. The two most prevalent architectural designs are the worm gear slew drive, which offers high reduction ratios and inherent self-locking capabilities, and the spur gear slew drive, prized for its high efficiency and compactness. This configuration simplifies machine architecture, saves space, and reduces the overall number of parts, making it a cornerstone component in heavy machinery and precision equipment where reliability under extreme stress is paramount.

Why Slew Drive Operation Generates Noise

Operational noise in a slew drive is an acoustic signature that can range from a benign, low-level hum indicating normal operation to a severe, loud grinding or knocking that signals imminent failure. Understanding the root cause of these sounds is critical for predictive maintenance and preventing catastrophic downtime. The noise originates from vibrations within the drive components, and these vibrations are triggered by a variety of mechanical conditions.

A low, consistent humming or whirring sound during operation is often normal, especially in worm gear slew drives. This is primarily caused by the sliding contact inherent in the meshing of the worm and the worm wheel (the gear on the slewing ring). This sliding action, combined with the elastic deformation of the gear teeth under load, generates a characteristic operational sound. The frequency and pitch of this sound will change with rotational speed. However, a pronounced howling or whining noise typically points directly to lubrication issues. Insufficient lubrication, the use of an incorrect grease type (e.g., a viscosity that is too high for the operating temperature), or degraded lubricant that has lost its lubricating properties all lead to inadequate oil film formation between meshing teeth and rolling elements. This results in metal-to-metal contact, increased friction, and a distinct high-pitched whine. Contamination of the grease with abrasive particles like sand or metal dust will exacerbate this, effectively lapping the components and accelerating wear, which also increases noise levels.

A rhythmic clicking, knocking, or popping sound is a more serious indicator of mechanical damage. This is frequently caused by brinelling—permanent indentations on the raceways of the slewing bearing from shock loads or improper installation. As the rolling elements (balls or rollers) pass over these dents, they create a periodic knocking sound. Similarly, damage to the gear teeth, such as chipping, pitting, or severe wear, will cause a clicking noise that corresponds to the mesh frequency of the gears. Excessive gear backlash, often resulting from wear or improper initial adjustment, allows the pinion to slightly jump and slam into the ring gear teeth during direction changes or under variable loads, producing a distinct clunking or hammering sound. In severe cases, a cracked or broken gear tooth will generate a very loud and violent knocking noise with every revolution.

Installation and alignment errors are another major source of noise and vibration. If the slew drive is mounted on a surface that is not flat and rigid, the internal rings can become distorted when the mounting bolts are tightened. This distortion creates preload in the bearing raceways, drastically increasing rotational resistance and generating a constant grinding or rumbling noise. Misalignment between the drive motor/gearbox and the slew drive input, or misalignment between the pinion and the ring gear, creates uneven load distribution. This can lead to edge loading on gears and bearings, causing a high-pitched squeal or grinding noise due to the localized stress. Finally, external factors can be the culprit. A loose mounting structure that flexes under load, failing motor bearings, or even a damaged seal rubbing against a rotating surface can all generate noises that may be mistakenly attributed to the slew drive itself. A thorough inspection is required to isolate the exact source.

Characteristics of Slew Drive

Slew Drives are defined by a distinct set of engineering characteristics that make them indispensable for high-torque, low-speed rotational applications. Their most defining feature is the exceptionally high torque output delivered in a compact and integrated package. By combining a high-ratio speed reducer with a large-diameter slewing ring, they achieve massive mechanical advantage, allowing relatively small input motors to control and move immensely heavy loads with precision. This integrated design eliminates the need for custom-designed mounting solutions for separate components, simplifying machine design, saving space, and enhancing overall reliability.

A key operational characteristic of worm gear-based slew drives is their inherent self-locking capability. The design of the worm and worm wheel creates a high friction angle that prevents back-driving. This means that when the input drive stops, the load is immediately and reliably held in position without the need for an external braking system, a critical safety feature in applications like crane booms or solar trackers. Furthermore, slew drives are renowned for their robustness and durability. They are constructed from high-strength, hardened steel alloys and are designed to operate reliably under severe conditions, including exposure to heavy shock loads, vibrations, and harsh environmental elements, thanks to their protective sealing systems.

Their design offers significant flexibility. They can be configured with the gear on the inner or outer ring, sourced with different sealing and lubrication options for various environments, and customized with a range of input motors (electric, hydraulic) and gear reduction ratios to meet the exact torque and speed requirements of a specific application. Whether using a worm gear for self-locking or a spur gear for higher efficiency, the slew drive provides a versatile solution for powered rotation.

Applications of Slew Drive

The application of slew drives is extensive across industries that require robust, controlled, and powerful rotational movement. In the construction and heavy machinery sector, they are the fundamental actuation system in the boom rotation of mobile cranes, enabling precise positioning of heavy loads. They are also critical in concrete pump trucks for controlling the placement boom and in excavators for providing rotation.

The renewable energy industry is a major and growing application field. Slew drives are the core component in solar tracking systems for both photovoltaic (PV) panels and concentrated solar power (CSP) systems. They provide the precise, powerful rotation needed to accurately angle solar arrays throughout the day, significantly increasing energy capture. Similarly, they are used in the yaw and pitch control systems of wind turbines, adjusting the nacelle and blades to optimize performance.

In industrial automation and material handling, these drives are essential. They operate the rotating bases of robotic welding and assembly arms, provide motion for indexing tables on heavy-duty machining centers, and are found in rotary conveyors and palletizers. The mining and agricultural industries rely on them for robust performance in stackers, reclaimers, and heavy-duty tractors. Furthermore, their precision and holding power make them suitable for specialized applications such as radar and satellite antenna positioning, medical imaging equipment like CT scanners, and even in deck cranes and winches on marine vessels.

Factors Influencing the Price of Slew Drive

The price of a slew drive is determined by a confluence of technical specifications, material choices, and commercial factors. The single largest cost driver is often the size and material of the core slewing ring and gearing. Larger diameters require more raw material and more complex machining processes. The grade of steel and the extent of heat treatment (e.g., induction hardening) applied to the raceways and gear teeth significantly impact cost.

The level of customization and complexity is another major determinant. A standard, catalogued unit is more economical than a fully custom-designed drive. Customizations such as special gear specifications, unique mounting hole patterns, specific seal materials for extreme temperatures, special surface coatings, and integrated sensors drastically increase manufacturing overhead. The specifications of the included components, namely the type and power of the input motor and the design of the gear reducer, also form a significant portion of the total cost.

Performance requirements directly influence price. Drives manufactured to standard industrial tolerances are cost-effective. Those produced to ultra-precise tolerances for high-precision applications, which require 100% non-destructive testing (NDT) and full material traceability, command a premium. Finally, order quantity and external factors play a role. Large volume orders benefit from economies of scale. Global fluctuations in steel prices, international shipping costs, and import/export tariffs can also cause price variations.

Introducing a Supplier of Slew Drive

For engineers seeking a reliable source for high-performance slew drives, LYRADRIVE stands as a manufacturer with deep expertise in the engineering and production of these integrated systems. The company provides comprehensive technical support, guiding customers through selection, installation, and maintenance best practices to ensure optimal performance, longevity, and quiet operation. This support is backed by a rigorous quality management system governing every production stage, from material forging and precision gear cutting to heat treatment, final assembly, and testing. By offering advanced manufacturing capabilities and a commitment to delivering robust and reliable drive solutions, LYRADRIVE has established itself as a trusted partner for a global clientele across diverse industries such as solar tracking, construction, industrial automation, and material handling.