High Precision Coaxial Flange Gear Slew Drive Inspection

What is Flanged Ball Slewing Bearings

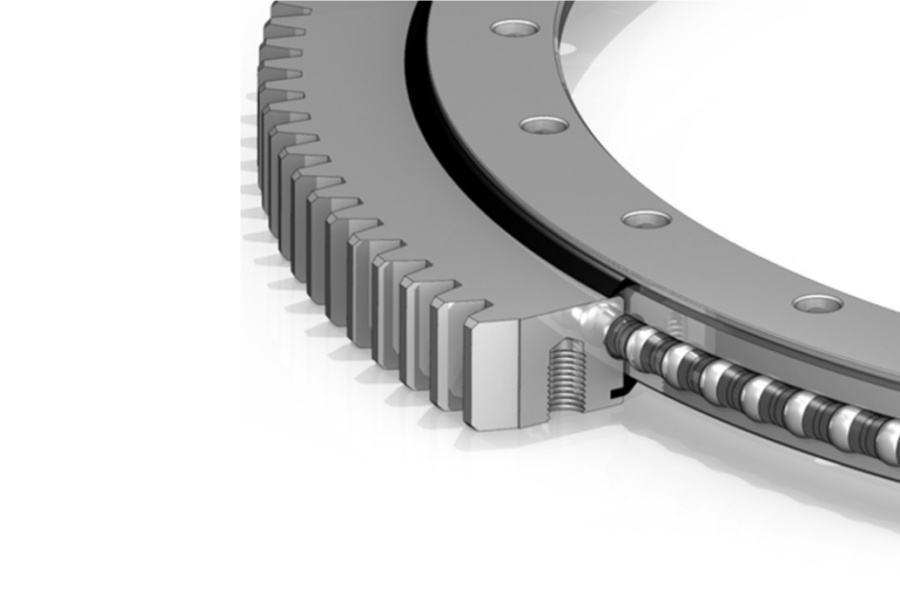

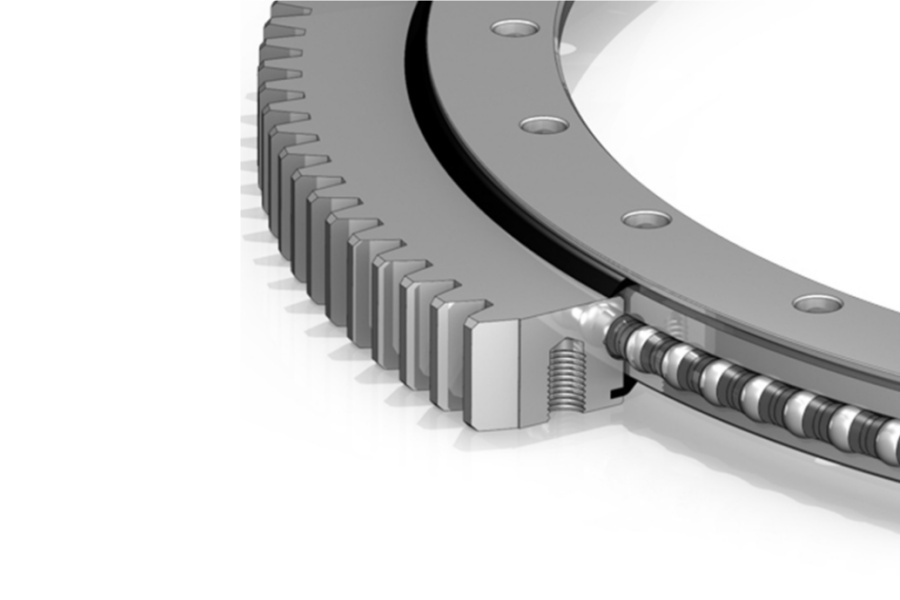

Flanged Ball Slewing Bearings are a specialized type of rotary rolling-element bearing characterized by an integrated mounting flange on one or both of its rings. This flange is a perpendicular radial extension that contains precisely machined bolt holes, allowing for direct and secure bolting to adjacent machine structures without the need for additional mounting housings or adapter plates. Unlike conventional bearings that are merely components within a system, flanged ball slewing bearings are integral structural elements that form a direct and critical connection between a machine's stationary base and its rotating platform. Their construction features two robust steel rings with precision-ground raceways that accommodate a single or double row of balls as the rolling elements. These balls are typically spaced and guided by polyamide or metallic separators to ensure even load distribution and minimize friction. A quintessential feature of many units is the inclusion of an integrated gear, meticulously machined onto the periphery of either the inner or outer ring, which meshes with a pinion to create a highly efficient and compact drive system for powered rotational movement. Furthermore, advanced multi-lip sealing systems are integrated to protect the internal rolling contact surfaces and gear teeth from invasive contaminants, thereby ensuring long-term reliability and consistent performance. This design, combining support, rotation, and drive in a single unit with integrated mounting, makes them indispensable for applications requiring compact design and high precision.

High Precision Coaxial Flange Gear Slew Drive Inspection

The manufacturing of a high-precision coaxial flange gear slew drive does not conclude with assembly; it is validated through a series of rigorous, quantitative inspections that verify its geometric accuracy, rotational precision, and operational performance under simulated load. These inspections are non-negotiable for applications demanding exceptional repeatability and positioning accuracy, such as in medical imaging, optical positioning, or advanced automation. The process is a multi-faceted verification of the drive's core components and its integrated function.

The first critical inspection is the measurement of face runout on the slewing bearing's flange. This parameter is a direct indicator of the bearing's axial manufacturing precision and overall geometric integrity. Face runout is measured by mounting a precision dial indicator on a fixed base and positioning its probe perpendicular to the mounting flange's face. As the bearing is slowly rotated through a full 360 degrees, the dial indicator records the maximum deviation in the axial direction. A minimal face runout value signifies that the flange surface is exceptionally flat and parallel to the bearing's axis of rotation, and that the raceways have been machined and heat-treated with high consistency. This is crucial because excessive face runout translates directly into wobble or axial oscillation of the entire mounted platform, severely degrading the system's rotational accuracy and leading to uneven wear, vibration, and premature failure. For high-precision drives, face runout is typically specified to be within a few microns or arc-seconds.

The second paramount inspection is the measurement of gear runout (radial runout). This test evaluates the accuracy of the integrated gear teeth relative to the bearing's central axis of rotation. A specialized dial indicator is positioned with its probe oriented radially against the flank of a gear tooth. As the bearing is rotated, the runout of the gear teeth is recorded. This measurement reflects the cumulative errors in gear hobbing, heat treatment distortion, and the concentricity of the gear with the raceways. A low gear runout value is absolutely essential for achieving smooth, low-vibration meshing with the drive pinion, ensuring consistent backlash, and enabling high-precision indexing and positional repeatability. Excessive gear runout causes velocity fluctuations, increased noise, and non-uniform load distribution across the gear teeth, leading to accelerated wear and potential tooth failure.

Finally, the drive must undergo a loaded running test. This dynamic inspection simulates real-world operating conditions to verify overall performance. The assembled slew drive is mounted in a test rig and subjected to a specified percentage of its rated moment load. Operators then manually or slowly rotate the drive under this load to check for any binding, irregular resistance, or audible anomalies that might indicate improper assembly, contamination, or misalignment. Following this qualitative check, a quantitative measurement of starting torque is performed. A force gauge is used to measure the tangential force required to turn the input pinion or a lever arm of known length attached to it. This force value is then multiplied by the lever arm distance to calculate the precise input starting torque under load. This measured torque is critically compared against design calculations to ensure it falls within the acceptable range, confirming that the selected drive motor and reducer will be appropriately sized to overcome initial static friction and operate the system efficiently and reliably.

Characteristics of Flanged Ball Slewing Bearings

Flanged Ball Slewing Bearings are defined by a unique set of engineering characteristics that make them exceptionally versatile and reliable. Their most distinctive feature is the integrated mounting flange, which simplifies machine design by eliminating the need for separate bearing housings, thereby reducing part count, saving space, and facilitating easier installation and maintenance. This design enhances the structural integrity of the overall assembly by providing a large, stable surface for secure bolting. They are engineered to manage complex combinations of loads—axial, radial, and moment loads—simultaneously within a single, compact unit, which simplifies architecture and improves the stiffness of the entire mechanical system.

Another key characteristic is their high precision and smooth operation. The use of balls as rolling elements, combined with precision-ground raceways, results in lower friction and more consistent starting torque compared to roller designs. This makes them ideal for applications requiring smooth, precise rotation. The option for integrated gearing, either on the inner or outer ring, transforms the bearing into a compact rotational drive mechanism, further enhancing its functionality. Durability is engineered into their core through the use of high-carbon chromium steel (e.g., 50Mn, 42CrMo4) subjected to advanced heat treatment processes like induction hardening for the raceways and gears. This provides a extremely hard, wear-resistant surface while maintaining a tough, shock-absorbing core. Furthermore, they are equipped with advanced multi-lip sealing systems that provide excellent protection against contaminants and retain lubrication, ensuring long service life even in harsh environments. Their design allows for significant customization in size, gear type, sealing solutions, and mounting hole patterns to meet the exact requirements of a vast array of applications.

Applications of Flanged Ball Slewing Bearings

The application of flanged ball slewing bearings is extensive across industries that require compact, precise, and reliable rotational movement. In robotics and industrial automation, they are fundamental in the joints of robotic arms, rotary tables on CNC machining centers, and precision indexing fixtures, where their high precision and stiffness are critical. The medical industry relies on specially designed, high-precision, and often cleanroom-compatible versions for advanced diagnostic equipment such as CT and MRI scanners, where they enable the smooth, quiet, and precise rotation of heavy imaging gantries.

In the renewable energy sector, they are employed in solar tracking systems for precise positioning of photovoltaic panels and in the pitch and yaw systems of small to medium-sized wind turbines. The aerospace and defense sectors utilize them in radar and satellite communication antennas for accurate positioning and tracking, as well as in optical targeting systems. They are also found in a multitude of other applications, including precision turntables, packaging machinery, material handling rotators, and anywhere a compact, flanged bearing solution with high rotational accuracy is required.

Factors Influencing the Price of Flanged Ball Slewing Bearings

The price of a flanged ball slewing bearing is determined by a complex interplay of technical specifications, material choices, and commercial factors. The single largest cost driver is often the raw material. The type, grade, and quantity of steel required have a direct and significant impact. Standard carbon chromium steel is common, but applications requiring enhanced corrosion resistance necessitate stainless steel, which sees a substantial price increase. The physical dimensions—primarily the diameter, flange size, and cross-section—directly scale the material cost and weight.

The complexity of the manufacturing process and the level of customization are another major determinant. A standard, off-the-shelf bearing is more economical than a fully customized one. Customizations such as integrated gearing (including the gear type, module, and precision grade), special sealing arrangements, unique mounting hole patterns, and special surface coatings all add significant steps, specialized tooling, and time to the production process, increasing the manufacturing overhead.

The required precision tolerance grade and performance specifications dramatically influence the price. A bearing manufactured to standard industrial tolerances is cost-effective. However, one produced to ultra-precise, micron-level tolerances for high-precision applications, requiring 100% non-destructive testing (NDT), full material traceability, and extended performance validation, will command a premium price due to the extensive additional labor, slower production pace, and advanced quality assurance protocols involved.

The quantity ordered is a fundamental economic factor governed by economies of scale. Large volume production runs allow the manufacturer to amortize fixed costs over many units, drastically reducing the price per bearing. A one-off prototype or a small batch order will have a significantly higher unit cost. Finally, external supply chain factors like global fluctuations in steel prices, international logistics and shipping costs, and import/export tariffs and duties can also cause fluctuations in the final price.

Supplier of Flanged Ball Slewing Bearings

For engineers and procurement specialists seeking a reliable source for high-precision flanged ball slewing bearings, LYRADRIVE stands as a manufacturer with deep expertise in the engineering and production of these critical components. The company provides comprehensive technical support that includes guidance on selection, installation, and the interpretation of precision inspection protocols like runout measurement and load testing. This application-focused support is backed by a rigorous quality management system that governs every stage of production, from material selection and forging to precision machining, heat treatment, and final assembly and inspection. By offering advanced manufacturing capabilities, engineering-led problem-solving, and a commitment to delivering high-accuracy and reliable products, LYRADRIVE has established itself as a trusted partner for a global clientele across diverse industries such as medical imaging, industrial automation, robotics, and renewable energy.