Gear Backlash Analysis In Spur Gear Slew Drive

What is Spur Gear Slew Drive

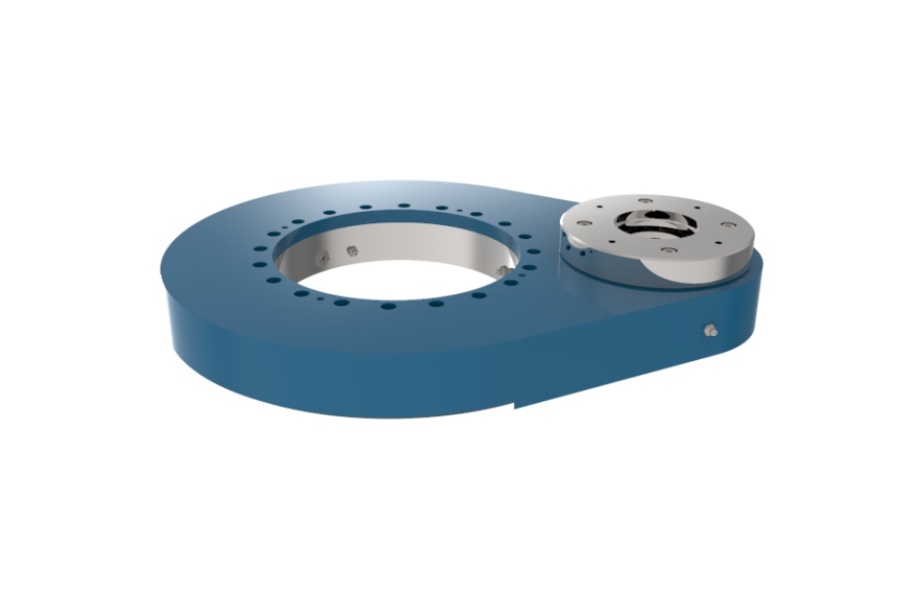

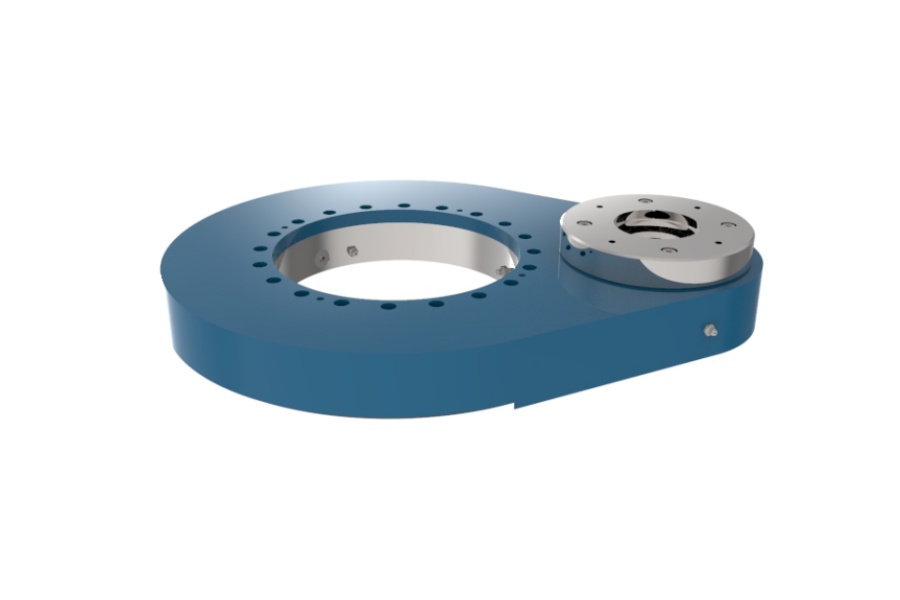

Spur Gear Slew Drive is a fully integrated mechanical actuator system designed to provide controlled, high-torque rotational movement about a single axis. It represents a complete fusion of a robust drive motor (typically hydraulic or electric), a high-ratio speed reducer such as a worm gearbox, and a large-diameter slewing ring bearing with a spur (straight-cut) gear machined directly onto either its inner or outer ring. This integrated design distinguishes it from systems where these components are sourced and assembled separately. The primary function of a slew drive is to efficiently transform the high-speed, low-torque output of its input motor into a slow-speed, high-torque rotational output, enabling it to manage immense loads with precise control. The term "spur gear" specifically refers to the geometry of the gear teeth on the slewing ring; these teeth are straight and aligned parallel to the axis of rotation, which differentiates it from other drives using helical or bevel gears. This configuration is prized for its manufacturing simplicity, ease of installation and maintenance, and its ability to deliver high power transmission efficiency in a compact and robust package, making it a cornerstone component in heavy machinery where reliability under extreme stress is paramount.

Gear Backlash Analysis In Spur Gear Slew Drive

Gear backlash, defined as the precise clearance between the meshing teeth of the slewing ring gear and the driving pinion in a spur gear slew drive, is not a manufacturing defect but a critical design parameter that must be meticulously engineered and controlled based on the specific application requirements. It is the angular distance the output gear can move without the input gear moving. This analysis delves into the sources, implications, and control strategies for backlash, which is a paramount factor influencing positioning accuracy, operational smoothness, noise levels, and overall system longevity.

The requirement for backlash is profoundly application-dependent. For instance, in applications involving continuous rotation in a single direction, such as a conveyor rotator or a slow-turning mixer, backlash is largely inconsequential. The primary requirements are smooth power transmission and high durability, as the constant direction of rotation keeps the gear teeth always in contact on one flank, effectively making the backlash value irrelevant to operation. Conversely, in high-speed, high-load applications like the yaw drive of a wind turbine or a rapidly indexing industrial robot, excessive backlash becomes highly detrimental. It can lead to significant issues with vibration, acoustic noise, and non-linear motion caused by repeated impacts as the pinion tooth slams into the ring gear tooth upon changes in torque direction or load. For these applications, a tightly controlled, minimal backlash is essential to ensure smoother power transfer, reduce dynamic loads, and mitigate wear. The most stringent demands come from applications requiring precise positioning and repeatability, such as automated assembly lines, medical imaging equipment (CT/MRI scanners), or satellite tracking antennas. Here, backlash directly translates to lost motion, preventing the system from achieving accurate stopping positions or maintaining precise alignment. For these systems, backlash is often specified to be within one arc-minute or even less, necessitating ultra-precise manufacturing and specialized anti-backlash designs.

The manufacturing and assembly process is the first line of defense in controlling backlash. In a standard slew drive designed for general-duty applications, the ring gear and pinion are machined (hobbled or shaped) and then heat-treated (induction hardened) to achieve the necessary surface hardness and wear resistance. After assembly, backlash is checked to ensure it falls within a broad acceptable range that guarantees smooth operation without binding. For drives destined for high-speed or high-load scenarios, a significant upgrade involves precision gear grinding. After the initial machining and heat treatment, both the ring gear and the pinion undergo a finishing process on a precision gear grinder. This critical step corrects any micro-geometric deviations or minor distortions induced during heat treatment, achieving a superior tooth profile, lead, and pitch accuracy. This results in a dramatically smoother meshing action, significantly reduced vibration and noise, and a more consistent and predictable backlash value across the entire gear rotation.

For applications where ultra-precise positioning is non-negotiable, standard manufacturing processes, even with grinding, may not suffice due to inherent factors like gear tooth runout. This is where advanced anti-backlash designs are implemented. The most effective mechanical solution is the dual-pinion or multi-pinion anti-backlash system. In this design, two pinions are spring-loaded or mechanically adjusted to mesh with the same ring gear but are preloaded against opposite flanks of the gear teeth. This ingenious arrangement effectively eliminates all free rotational movement by ensuring constant contact on both sides of the tooth, thereby reducing the effective backlash to near zero. This system provides exceptional positional accuracy without requiring astronomically expensive, perfection-level gear machining. An additional major benefit of a multi-pinion system is load sharing. The total driving torque is distributed between two or more pinions, reducing the load on each individual gear set. This is particularly advantageous for high-precision applications involving high inertial loads, as the impact forces during precise stopping are distributed, minimizing stress and wear on the gear teeth and significantly enhancing the drive's overall lifespan and reliability.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drives are defined by a distinct set of engineering characteristics that make them indispensable for high-torque, low-speed rotational applications. Their most defining feature is the exceptionally high torque output delivered in a compact and integrated package. By combining a high-ratio worm gear reducer with a large-diameter slewing ring, they achieve massive mechanical advantage, allowing relatively small input motors to control and move immensely heavy loads with precision. This integrated design eliminates the need for custom-designed mounting solutions for separate components, simplifying machine design, saving space, and reducing the overall number of parts in the system, which enhances reliability.

A key operational characteristic is their inherent self-locking capability when a worm gear reducer is employed. The design of the worm and worm wheel creates a high friction angle that prevents back-driving. This means that when the input drive stops, the load is immediately and reliably held in position without the need for an external braking system. This is a critical safety feature in applications like crane booms, solar trackers, or lifting platforms where maintaining a stationary position under load is absolutely essential. Furthermore, spur gear slew drives are renowned for their robustness and durability. They are constructed from high-strength, hardened steel alloys (e.g., 42CrMo4 for rings) and are designed to operate reliably under severe conditions, including exposure to heavy shock loads, vibrations, and harsh environmental elements, thanks to their protective sealing systems.

The use of a spur gear offers specific advantages. Compared to helical gears, spur gears are simpler to manufacture, inspect, and maintain. Their straightforward geometry allows for easier alignment during installation and meshing with the pinion. While they can be slightly noisier than helical gears at very high speeds, this is less of a concern in the slow-speed, high-torque applications where slew drives excel. Finally, these drives offer significant design flexibility. They can be configured with the gear on the inner or outer ring, sourced with different sealing and lubrication options for various environments, and customized with a range of input motors (electric, hydraulic) and gear reduction ratios to meet the exact torque and speed requirements of a specific application.

Applications of Spur Gear Slew Drive

The application of spur gear slew drives is extensive across industries that require robust, controlled, and powerful rotational movement. In the construction and heavy machinery sector, they are the fundamental actuation system in the boom rotation of mobile cranes, enabling precise positioning of heavy loads. They are also critical in concrete pump trucks for controlling the placement boom and in excavators for providing rotation in compact swing drives.

The renewable energy industry is a major and growing application field. Slew drives are the core component in solar tracking systems for both photovoltaic (PV) panels and concentrated solar power (CSP) systems. They provide the precise, powerful rotation needed to accurately angle solar arrays throughout the day, significantly increasing energy capture. Similarly, they are used in the yaw and pitch control systems of smaller wind turbines, adjusting the nacelle and blades to optimize performance.

In industrial automation and material handling, these drives are essential. They operate the rotating bases of robotic welding and assembly arms, provide motion for indexing tables on heavy-duty machining centers, and are found in rotary conveyors and palletizers. The mining and agricultural industries rely on them for robust performance in stackers, reclaimers, and heavy-duty tractors. Furthermore, their high precision and holding power make them suitable for specialized applications such as radar and satellite antenna positioning, medical imaging equipment like CT scanners, and even in deck cranes and winches on marine vessels.

Factors Influencing the Price of Spur Gear Slew Drive

The price of a spur gear slew drive is determined by a confluence of technical specifications, material choices, and commercial factors. The single largest cost driver is often the size and material of the core slewing ring. Larger diameters require more raw material and more complex machining processes. The grade of steel (e.g., standard 50Mn or high-strength 42CrMo4) and the extent of heat treatment (induction hardening) applied to the raceways and gear teeth significantly impact cost, as does the choice of rolling element (ball vs. more expensive crossed roller).

The level of customization and complexity is another major determinant. A standard, catalogued unit is more economical than a fully custom-designed drive. Customizations such as special gear specifications (module, precision grade), unique mounting hole patterns, specific seal materials for extreme temperatures, special surface coatings (e.g., anticorrosion treatments), and integrated sensors drastically increase manufacturing overhead. The specifications of the included components, namely the type and power of the input motor (standard electric motor vs. a customized hydraulic motor) and the design of the gear reducer, also form a significant portion of the total cost.

Performance requirements directly influence price. Drives manufactured to standard industrial tolerances are cost-effective. Those produced to ultra-precise, micron-level tolerances for applications like medical imaging or aerospace, which require 100% non-destructive testing (NDT), full material traceability, and extended performance validation, command a premium. Finally, order quantity and external factors play a role. Large volume orders benefit from economies of scale, reducing the unit cost. Global fluctuations in steel prices, international shipping costs, and import/export tariffs can also cause price variations.

Supplier of Spur Gear Slew Drive

For engineers seeking a reliable source for high-performance spur gear slew drives, LYRADRIVE stands as a manufacturer with deep expertise in the engineering and production of these integrated systems. The company provides comprehensive technical support, guiding customers through selection, installation, and maintenance best practices to ensure optimal performance and longevity. This support is backed by a rigorous quality management system governing every production stage, from material forging and precision gear hobbing to heat treatment, final assembly, and testing. By offering advanced manufacturing capabilities and a commitment to delivering robust and reliable drive solutions, LYRADRIVE has established itself as a trusted partner for a global clientele across diverse industries such as solar tracking, construction, and industrial automation.