Why Elastic Washers Are Avoided In Slewing Bearing Bolt Installation

What is a Slewing Bearing?

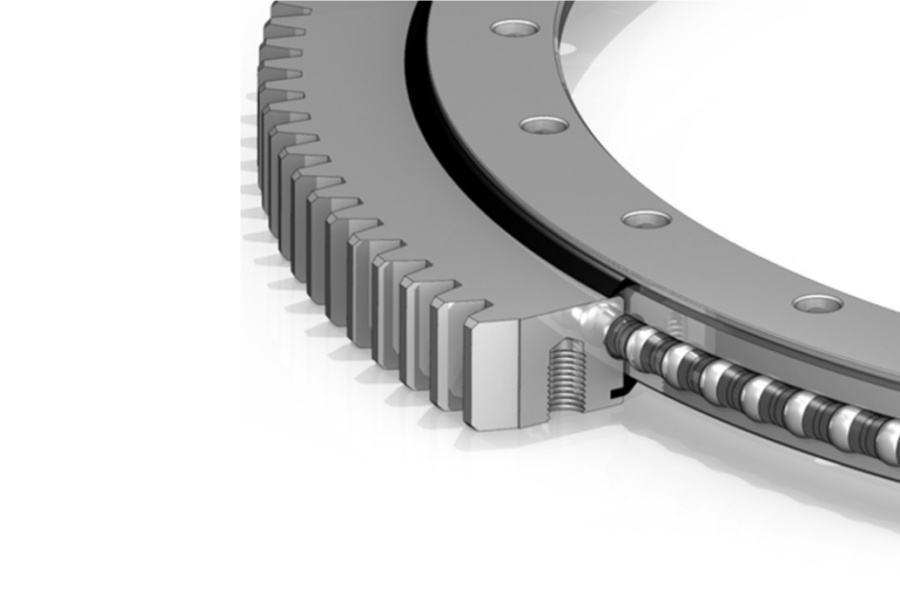

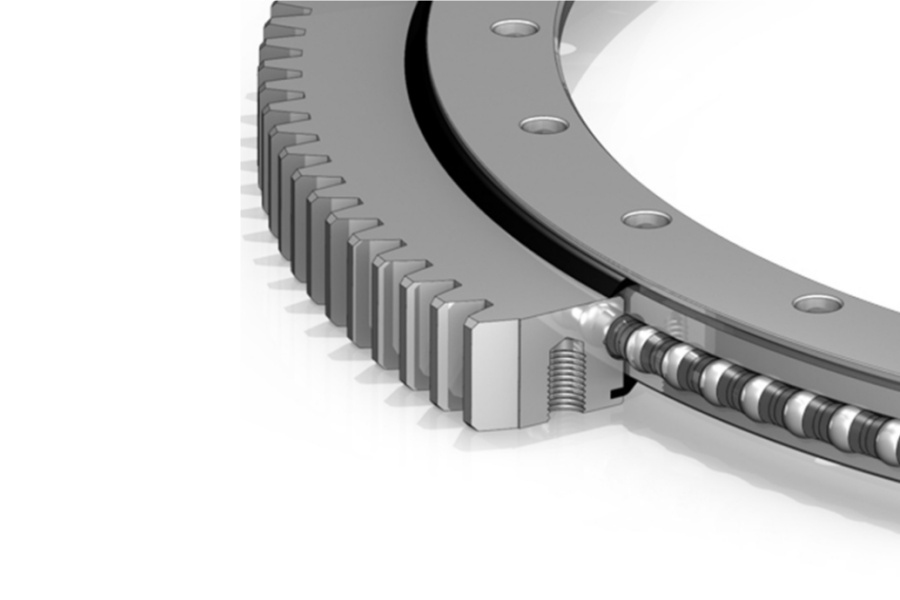

Slewing Bearing, also known as a turntable bearing or rotary joint, is a highly engineered rotational bearing component designed to handle exceptionally demanding combinations of axial, radial, and moment loads simultaneously. Unlike standard bearings, slewing bearings feature integrated mounting holes and often incorporate gear teeth directly on their inner or outer ring. Their robust construction allows them to facilitate smooth, controlled rotation between heavy structures under immense stress, such as the upper structure (house) and undercarriage of an excavator or the nacelle and tower of a wind turbine. These bearings are fundamental components in machinery requiring significant load-bearing capacity coupled with precise rotational movement.

Why Elastic Washers Are Prohibited for Slewing Bearing Bolts

The explicit instruction in slewing bearing installation manuals to avoid elastic washers (like spring washers or lock washers) stems from fundamental engineering principles critical to the bearing's performance and longevity. While elastic washers are common in many general machinery applications to prevent loosening under vibration, their use with slewing bearings is counterproductive and potentially damaging for several key reasons:

Fundamental Reliance on Friction, Not Spring Force: Slewing bearings operate under extreme loads. Consequently, their mounting bolts are invariably high-strength fasteners, typically Grade 10.9 or higher. The integrity of this bolted joint relies primarily on generating and maintaining an extremely high clamp load (preload force) through bolt tension. This high preload creates massive friction between the connected parts (the bearing ring flange and the mating structure), which is the primary mechanism resisting slippage and loosening under operational loads and vibrations. Elastic washers introduce a compressible element into this critical joint. Under the immense preload required, the washer compresses and loses its spring force. Crucially, this compression means the washer cannot maintain sufficient additional force to be effective against the high-frequency, high-magnitude vibrations typical in slewing bearing applications. Its intended anti-loosening function becomes negligible or non-existent under these conditions.

Risk of Inducing Plastic Deformation: Elastic washers have a significantly smaller, often uneven, contact surface area compared to flat washers. When the high preload force required for slewing bearing bolts is applied through an elastic washer, this force becomes concentrated onto a much smaller area of the bearing ring's mounting surface. Slewing bearing rings, while robust, are precisely machined components. Concentrating immense force onto a small area significantly increases the localized contact pressure. This pressure can easily exceed the yield strength of the bearing ring material (or sometimes the mating structure material), leading to permanent plastic deformation (indentation) of the mounting surface beneath the washer. Once this deformation occurs, the clamp load exerted by the bolt is irreversibly reduced. This creates a dangerous situation where the bolt is effectively loose from the outset, even if the nut hasn't visibly backed off.

Exacerbation by Operational Loads: Slewing bearings are specifically designed to handle large overturning moments (tilting forces). During operation, these moment loads constantly shift the pressure distribution across the mounting surface. The areas already weakened by potential plastic deformation caused by the elastic washer become critical failure points. The cyclic nature of these loads works to progressively worsen any initial deformation. Furthermore, the inherent "springiness" or tendency of some elastic washers to splay open under load can create instability within the joint. This instability, combined with the high loads and vibrations, dramatically accelerates wear and fatigue, potentially leading to catastrophic failure of the bolt, the washer itself, or the bearing mounting surface.

Incompatibility with Correct Alternatives: The proven and correct method for preventing loosening in high-strength bolted joints like slewing bearings involves maintaining the designed clamp load reliably. This is achieved through:

Precise Bolt Tightening: Using calibrated torque wrenches or, preferably, hydraulic tensioning tools to apply the exact preload specified by the bearing manufacturer.

High-Quality Flat Washers: Properly sized, hardened flat washers (usually matching the bolt grade) are essential. They distribute the immense bolt clamping force over a much larger area of the mounting surface. This distribution drastically reduces localized contact pressure, preventing the plastic deformation that elastic washers cause. The larger contact area also provides greater stability against the bearing's overturning moments.

Thread Locking Compounds: Applying a high-strength, permanent thread-locking adhesive (like Loctite 270 or equivalent) to the bolt threads is the primary active anti-loosening measure. This adhesive cures anaerobically within the thread interface, creating a powerful mechanical lock that prevents vibrational loosening without compromising clamp load.

Essential Characteristics of Slewing Bearings

Understanding why specific installation practices like avoiding elastic washers are crucial requires appreciating the inherent characteristics of slewing bearings:

Extreme Load Capacity: Engineered to support immense axial, radial, and moment loads simultaneously, far exceeding standard bearings.

Integrated Design: Feature bolt holes for direct mounting to structures and often incorporate gear teeth for rotational drive.

Precision Components: Require precise manufacturing tolerances and high-quality materials (typically through-hardened alloy steel like 42CrMo4 or 50Mn) to ensure structural integrity and longevity under stress.

Low-Speed, High-Torque Operation: Primarily function in slow-rotation applications where high torque transmission is essential.

Robust Sealing: Employ sophisticated multi-lip seals to protect internal rolling elements (balls or rollers) and raceways from harsh environmental contaminants like dirt, water, and dust.

Lubrication Systems: Include lubrication channels and zerks for regular grease replenishment to minimize wear and friction.

Critical Safety Component: Failure often leads to catastrophic machine breakdown, significant downtime, costly repairs, and severe safety hazards.

Diverse Applications of Slewing Bearings

The unique load-handling capabilities of slewing bearings make them indispensable in a vast array of heavy machinery and equipment across numerous industries:

Construction Machinery: Excavators, mobile cranes, crawler cranes, concrete pump trucks, pile drivers, drilling rigs (enabling boom rotation and superstructure slew).

Material Handling: Tower cranes, harbor cranes, reach stackers, container handlers, forklifts, stacker-reclaimers.

Wind Energy: Yaw drives (rotating nacelle to face wind) and pitch drives (adjusting blade angle) on wind turbines.

Industrial Equipment: Turntables, indexing tables, welding positioners, heavy-duty robots, ladle turrets in steel plants, tunnel boring machines.

Mining: Bucket wheel excavators, draglines, stackers, ship loaders/unloaders.

Defense & Aerospace: Radar platforms, missile launchers, gun turrets, telescope mounts.

Medical: Heavy radiation therapy equipment (like linear accelerators - LINACs).

Recreation: Ferris wheels, large rotating platforms.

Factors Influencing Slewing Bearing Price

The cost of a slewing bearing varies significantly based on numerous technical and commercial factors:

Size & Dimensions: Larger diameter and cross-section bearings require substantially more material and complex manufacturing processes, directly increasing cost.

Load Capacity Requirements: Bearings engineered to withstand higher axial, radial, and moment loads demand more robust designs, larger rolling elements, higher-grade materials, and more precise hardening, all adding to the price.

Bearing Type & Complexity: Single-row ball bearings are generally the most economical. Double-row ball bearings, cross roller bearings, and three-row roller bearings are progressively more complex and expensive. Gear teeth (internal or external), tooth quality (milled vs. ground), and special tooth profiles add significant cost.

Material Grade & Quality: The type of alloy steel (e.g., standard 50Mn vs. higher-grade 42CrMo4), the quality of the steel sourcing, and the depth and uniformity of the through-hardening process critically impact durability and price.

Manufacturing Precision & Tolerances: Tighter machining tolerances for raceways, gear profiles, mounting surfaces, and bolt holes require more advanced equipment, skilled labor, and rigorous quality control, increasing manufacturing costs.

Sealing Requirements: The number of sealing lips, seal material quality (e.g., standard NBR vs. highly resistant FKM/Viton), and complexity of the seal design influence cost. Special sealing for extreme environments adds more.

Lubrication System: Standard grease zerks vs. centralized lubrication channels and ports.

Surface Treatments & Coatings: Corrosion protection like phosphate coatings, paint, or specialized treatments (e.g., Dacromet, Geomet) add cost.

Certifications & Testing: Compliance with specific international standards (ISO, DIN, AGMA) or customer-specific certifications, and requirements for additional non-destructive testing (NDT) or load testing, increase manufacturing overhead.

Quantity & Customization: Standard catalogue bearings are cheaper per unit than fully custom designs. Larger order quantities typically offer economies of scale.

Supplier Expertise & Reputation: Established manufacturers with proven quality, reliability, and technical support often command a premium over lesser-known or lower-quality producers.

Market Conditions & Raw Material Costs: Fluctuations in global steel prices and energy costs directly impact bearing pricing.

Supplier of Slewing Bearing

LYRADRIVE stands as a globally recognized supplier of high-performance slewing bearings and drive solutions, serving diverse industries with demanding rotational requirements. Leveraging over 15 years of expertise, LYRADRIVE focuses on engineering excellence, stringent quality control aligned with international standards (ISO 9001), and responsive customer support. They offer a comprehensive range of standard and fully customized slewing bearings, manufactured using premium materials and advanced processes to ensure optimal load capacity, durability, and smooth operation under the most challenging conditions. LYRADRIVE collaborates closely with clients from design consultation through installation support, providing reliable solutions that enhance equipment performance and minimize downtime. Their commitment to technical expertise and quality makes them a preferred partner for critical slewing bearing applications worldwide.