How To Improve Gear Processing Efficiency For Slewing Bearings

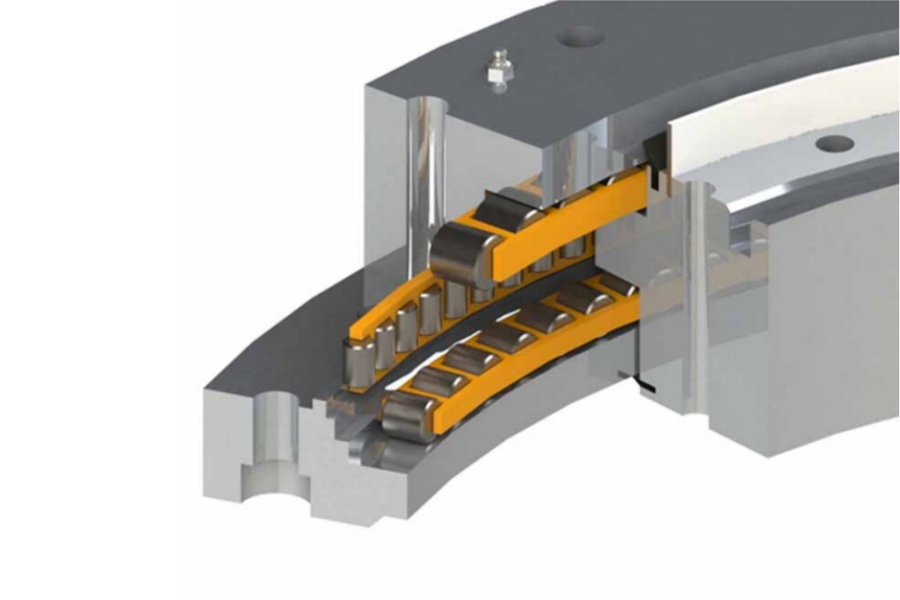

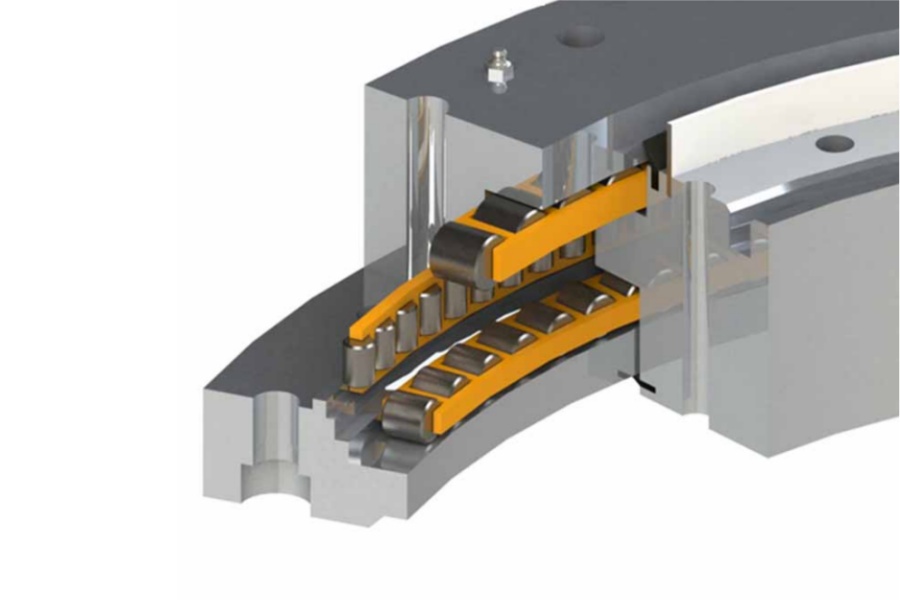

What Is A Slewing Bearing?

Slewing Bearing is a large-diameter rotational bearing engineered to handle extreme combined loads (axial, radial, and tilting moments) at low speeds. Its defining feature is integrated hardened gear teeth – machined directly onto the inner or outer ring – enabling direct torque transmission between rotating structures. As core components in cranes, excavators, wind turbines, and port equipment, gear machining constitutes over 40% of total manufacturing time, directly impacting delivery schedules and production capacity.

Why Gear Processing Efficiency Matters

Rising demand from infrastructure and renewable energy projects has intensified pressure on slewing bearing manufacturers. Traditional gear machining methods create significant bottlenecks:

Internal Gears: Exclusively processed via slow shaping (reciprocating cutting motion)

External Gears: Typically hobbed with moderate efficiency

Shared Limitations: Small depth-of-cut per pass, lengthy cycle times, and inability to handle large modules efficiently

High-Speed Milling: The Efficiency Breakthrough

CNC High-Speed Gear Milling has emerged as the transformative solution, particularly for large-diameter slewing bearings:

Revolutionary Internal Gear Machining

Utilizes specialized form cutters with multi-tooth engagement

Achieves 5-8X faster cycle times vs. shaping

Processes modules up to M40+ with deep cuts (10-15mm vs. shaping’s 1-3mm)

External Gear Advantages

Replaces hobbing with simultaneous multi-axis contouring

Reduces non-cutting time through optimized tool paths

Enables dry machining for faster chip evacuation

Core Technical Advantages

Adaptive Machining: Automatically adjusts feed rates to material hardness variations

Tool Longevity: Indexable carbide inserts withstand high cutting forces

Setup Reduction: Single clamping for tooth profiling and flank finishing

Strategic Implementation Guide

Internal Gears: Prioritize dedicated milling centers over shaping

External Gears: Adopt milling for modules > M12 and diameters > 2m

Pre-Machining: Use ultrasonic testing to identify material inconsistencies

Tooling: Deploy variable-helix cutters for vibration suppression

Post-Processing: Coordinate with induction hardening to minimize distortion correction

Key Slewing Bearing Characteristics

Tri-Load Capacity: Simultaneously manages axial, radial, and moment loads

Integrated Gearing: Hardened teeth enable direct drive functionality

Macro-Scale Dimensions: Diameters from 0.5m to 10m+

Custom Configurations: Modular designs for seals, lubrication, and mounting

Precision Demands: DIN 3962 Class 7-9 gear accuracy standards

Critical Applications Demanding Efficiency

Wind Energy: Yaw/pitch systems requiring 20,000+ cycle life

Mining: Excavator swing rings processing 500+ tons

Port Cranes: Container handlers with <0.1° positioning accuracy

Defense: Radar platforms needing vibration-free rotation

Solar Farms: Trackers requiring daily 180° rotations

Slewing Bearing Cost Drivers

Material Volume: Steel consumption scales cubically with diameter

Gear Specifications: Internal gears add 15-25% cost vs. external

Heat Treatment: Induction hardening accounts for 20-30% of COGS

Precision Requirements: Achieving DIN Class 7 adds 40% machining time

Logistics: Oversize transportation for bearings >4m diameter

Compliance: Certifications (DNV/GL, CE) increase documentation costs

Supplier of Slewing Bearing

LYRADRIVE delivers industry-leading slewing bearing solutions through strategic technological investments. Our dedicated high-speed milling centers slash internal gear production time by 70% while maintaining JIS B 1702 precision standards. With integrated manufacturing from forging to final grinding, we eliminate supply chain delays. Engineering teams collaborate with clients to optimize gear designs for manufacturability – balancing module size, tooth profile, and hardness specifications to reduce total cost. Rigorous QA protocols including coordinate scanning and gear analyzer testing ensure reliable performance under extreme loads. Contact LYRADRIVE to leverage our efficient production ecosystem for your next project.