What is Trailer Slewing Bearing

What is a Trailer Slewing Bearing?

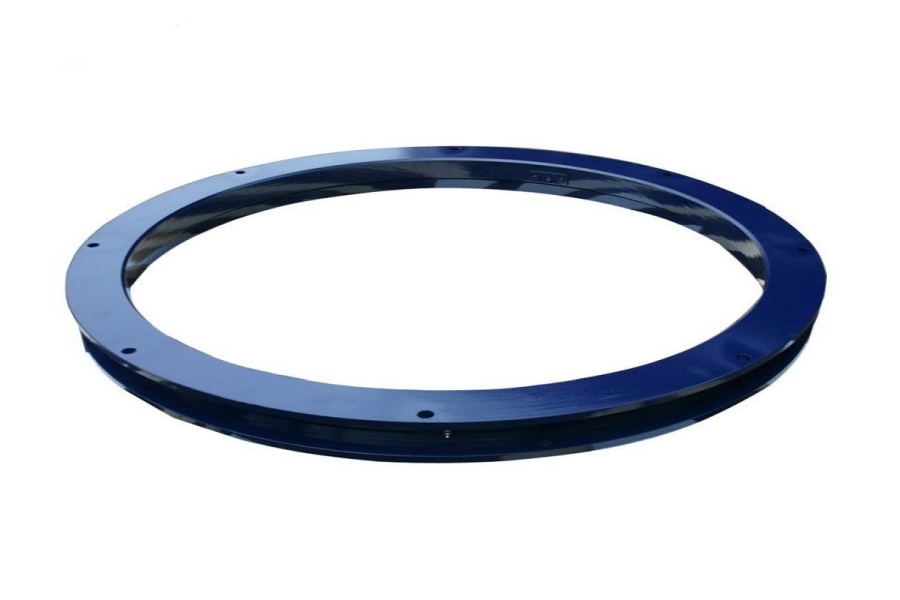

A Trailer Slewing Bearing is a heavy-duty rotational component designed to enable smooth 360-degree rotation between a trailer and its towing vehicle or between sections of a multi-axle trailer, ensuring precise maneuverability during transportation, loading, or specialized operations. This critical mechanical element combines a robust outer ring, rolling elements (balls or rollers), and an inner ring to handle axial, radial, and moment loads generated by the trailer’s weight, cargo shifts, and dynamic forces encountered on roads or worksites. Engineered for durability, these bearings are essential for applications requiring reliable rotation under stress, such as low-loader trailers transporting heavy machinery, tilt-bed trailers unloading equipment, or modular trailers used in military logistics. Their ability to withstand harsh environments—like dust, moisture, or extreme temperatures—makes them indispensable for industries prioritizing operational efficiency and safety.

Types of Trailer Slewing Bearings

Trailer Slewing Bearings are classified based on their internal design, load distribution mechanisms, and application-specific adaptations. Single-Row Ball Slewing Bearings utilize a single row of balls to manage moderate axial and radial loads, ideal for standard cargo trailers or light-duty tilt mechanisms where simplicity and cost-efficiency are prioritized. Double-Row Ball Slewing Bearings incorporate two parallel ball rows for enhanced load capacity and stability, commonly used in heavy-haul trailers transporting construction equipment or industrial machinery. Crossed Roller Slewing Bearings arrange cylindrical rollers in a 90-degree pattern to handle combined axial, radial, and moment loads with high precision, suited for specialized trailers like hydraulic modular transporters (HMTs) or self-steering axle systems requiring pinpoint rotational accuracy. Three-Row Roller Slewing Bearings combine separate axial and radial roller rows for extreme load scenarios, such as mining trailers carrying multi-ton ore loads or offshore logistics platforms. Sealed and Lubricated-for-Life Bearings feature integrated seals and pre-greased systems to minimize maintenance in environments prone to contamination, such as agricultural trailers operating in muddy fields or desert convoys exposed to sand.

Key Features of Trailer Slewing Bearings

The effectiveness of Trailer Slewing Bearings lies in their ability to balance strength, precision, and environmental resilience. High Load Capacity ensures they can support weights exceeding 100 tons while maintaining smooth rotation, critical for trailers hauling oversized industrial components or military vehicles. Corrosion Resistance, achieved through coatings like zinc-nickel plating or stainless steel construction, prolongs lifespan in coastal or chemically aggressive environments. Modular Design allows for easy integration into existing trailer systems, with pre-drilled mounting holes or customizable flange configurations simplifying installation. Low-Friction Operation, enabled by precision-ground raceways and high-quality rolling elements, reduces wear and energy consumption during frequent rotations. Weatherproof Sealing with IP67+ ratings protects internal components from water ingress, dust, and debris, ensuring reliability in rain, snow, or off-road conditions. Safety Locking Mechanisms, such as hydraulic brakes or manual pin locks, prevent unintended movement during loading or transport, enhancing operational safety.

Applications of Trailer Slewing Bearings

Trailer Slewing Bearings are pivotal in industries requiring versatile and robust transportation solutions. Heavy Haulage relies on them for low-loader trailers transporting turbines, excavators, or wind turbine blades, enabling precise alignment during loading and unloading. Construction and Mining use these bearings in tilt-bed trailers to dump aggregates or machinery efficiently, while modular trailers with self-steering axles navigate tight job sites. Agriculture employs them in grain trailers or manure spreaders requiring rotational flexibility in uneven terrain. Military Logistics integrates slewing bearings into tank transporters or modular trailers for rapid deployment in challenging environments. Renewable Energy projects utilize them to position solar panel carriers or wind turbine components during installation. Disaster Response teams depend on trailers with slewing bearings to transport and deploy emergency shelters or heavy equipment in flood zones or earthquake-affected areas.

Price Range

The cost of a Trailer Slewing Bearing varies widely depending on size, load capacity, and customization. Standard Single-Row Bearings for light-duty applications typically range from 1,500 to 5,000, offering basic rotational functionality for small cargo trailers. Heavy-Duty Double-Row or Crossed Roller Bearings designed for industrial or military use may cost between 8,000 and 30,000, depending on materials like hardened steel or corrosion-resistant alloys. Custom-Built Bearings for extreme conditions—such as offshore oil rig trailers or Arctic logistics platforms—can exceed $50,000, particularly when incorporating features like IoT sensors for load monitoring or explosion-proof certifications. Bulk orders for fleet operators often reduce per-unit costs by 10–20%, while expedited manufacturing or specialized coatings (e.g., ceramic hybrid bearings) may add 15–30% to the price.

Lifespan of Trailer Slewing Bearings

Operational longevity hinges on usage patterns, maintenance practices, and environmental exposure. Moderate-Duty Trailers in urban logistics or agriculture typically achieve 8–12 years of service with annual lubrication, seal inspections, and alignment checks. Heavy-Duty Applications like mining or military transport may shorten lifespan to 5–8 years due to constant high loads, abrasive environments, or frequent shock impacts. Harsh Conditions such as coastal salt spray or desert sandstorms can further reduce longevity to 3–6 years, even with advanced protective measures. Key maintenance strategies include using manufacturer-recommended greases, avoiding overloading beyond 80% of rated capacity, and replacing worn seals promptly to prevent contamination.

How to Choose the Right Trailer Slewing Bearing

Selecting the optimal bearing requires aligning technical specifications with operational demands. Calculate Load Requirements by evaluating axial, radial, and moment forces during peak operations, including dynamic factors like cargo shifts or uneven terrain, and apply a 1.5x safety factor to account for unexpected stresses. Prioritize Environmental Resistance—choose stainless steel or coated bearings for saltwater exposure, and sealed designs for dusty or wet environments. Assess Mounting Compatibility to ensure the bearing’s flange or bolt pattern matches the trailer’s chassis, avoiding costly modifications. Verify Certifications such as ISO 9001 or DNV-GL compliance for quality assurance, especially in regulated industries like aerospace or defense. Evaluate Total Cost of Ownership by considering long-term maintenance needs—premium bearings with lubricated-for-life systems may offset higher upfront costs through reduced downtime. Consult Experienced Suppliers who provide load-test reports, customization options, and post-sale support for troubleshooting.

Common Mistakes to Avoid

Underestimating Dynamic Loads by ignoring factors like cargo movement or road vibrations leads to premature bearing failure. Neglecting Corrosion Protection in humid or coastal areas accelerates component degradation—always opt for marine-grade materials. Using Incorrect Lubricants causes increased friction and overheating; adhere to manufacturer specifications for grease type and intervals. Overlooking Alignment Checks during installation results in uneven wear—use precision tools to ensure the bearing sits flush with mounting surfaces. Choosing Generic Bearings for Specialized Tasks, such as using standard models in high-shock mining trailers, compromises safety and performance. Delaying Maintenance allows minor issues like seal leaks to escalate into major repairs, increasing downtime and costs.

Trailer Slewing Bearing Supplier

LYRA Drive is a professional slewing bearings ,slew drive and gears manufacturer provides customized slew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.