What is Light Load Slewing Bearing

What is a Light Load Slewing Bearing?

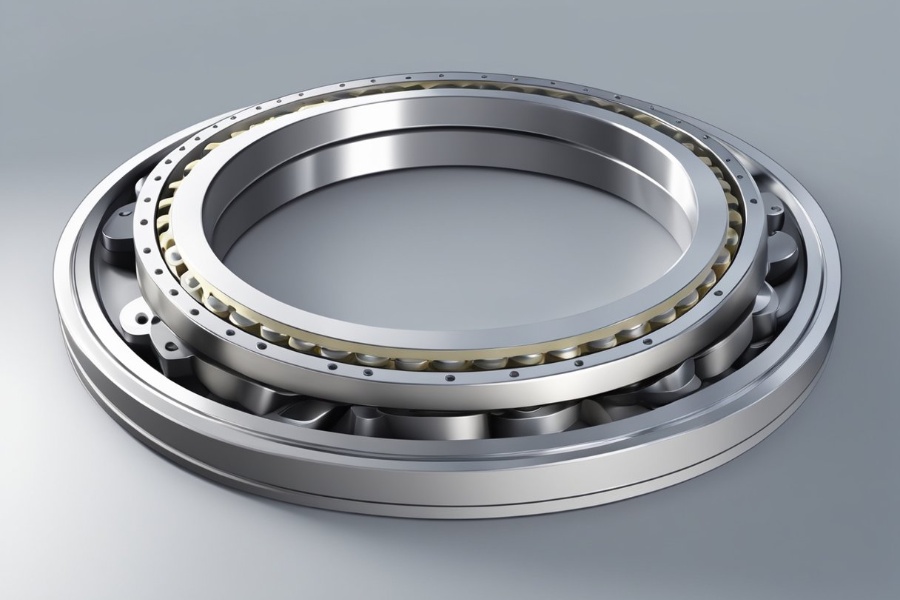

A light load slewing bearing is a compact rotational component engineered to manage relatively low axial, radial, and moment loads while enabling smooth 360-degree rotation in machinery and equipment. Designed for applications where heavy-duty bearings would be excessive, these units prioritize efficiency, space-saving design, and cost-effectiveness. Commonly used in systems like small robotics, medical devices, or solar trackers, light load slewing bearings often feature simplified constructions—such as single-row ball or roller configurations—and lightweight materials like aluminum alloys. Their streamlined build makes them ideal for scenarios demanding precision and reliability without the bulk or complexity of industrial-grade bearings.

Types of Light Load Slewing Bearings

Light load slewing bearings are available in multiple configurations to suit specific operational needs. Single-Row Ball Slewing Bearings utilize a single row of balls to handle moderate loads with minimal friction, making them suitable for rotating camera mounts, small conveyor systems, or adjustable furniture. Crossed Roller Slewing Bearings arrange cylindrical rollers in a perpendicular pattern, providing enhanced rigidity and precision for tasks like robotic arm joints or optical alignment tools. Three-Row Roller Slewing Bearings (Light-Duty Variants) combine axial and radial rollers in separate rows for balanced load distribution in applications such as light industrial turntables or packaging machinery. Flange-Mounted Slewing Bearings come with pre-drilled holes for easy integration into compact machinery, while Hollow Shaft Slewing Bearings feature a central bore for internal cable or hydraulic line routing in automated guided vehicles or small solar tracking systems.

Key Features of Light Load Slewing Bearings

Light load slewing bearings are defined by their user-friendly design and practical functionality. Compact dimensions allow seamless integration into tight spaces without compromising rotational efficiency, while lightweight materials like aluminum or low-carbon steel reduce overall system weight. Polished raceways and precision-engineered ball or roller assemblies ensure low friction operation, critical for applications such as medical imaging devices or adjustable monitors. Many models include integrated sealing systems to protect against dust, moisture, and debris in semi-harsh environments like outdoor garden equipment or agricultural tools. Modular designs simplify installation and maintenance, enabling quick component swaps without disassembling entire systems. Cost-effective manufacturing further enhances accessibility for startups, hobbyists, or projects with strict budget constraints.

Applications of Light Load Slewing Bearings

These bearings are widely used across industries and devices where heavy-duty components are unnecessary. In consumer electronics, they enable smooth rotation in adjustable monitor stands, rotating smart home devices, or ergonomic office furniture. Medical equipment such as X-ray machines, surgical robots, or dental chairs rely on their precision for accurate positioning. Renewable energy applications include small-scale solar trackers that adjust panel angles to optimize sunlight capture. Automation and robotics utilize them in collaborative robot joints, packaging machinery turntables, or 3D printer components. Even agricultural tools like portable seed spreaders or lightweight irrigation systems benefit from their durability in outdoor settings.

Price Range

Light load slewing bearings are generally more affordable than heavy-duty models, with costs varying based on size, material, and complexity. Basic single-row ball bearings for DIY projects or small machinery typically range from 50 to 200. Crossed roller variants designed for high-precision tasks in medical or optical equipment may cost between 300 and 1,000. Customized designs, such as flange-mounted or hollow shaft bearings, can range from 500 to 2,500, depending on material upgrades like stainless steel or specialty seals. Bulk orders for industrial automation systems may reduce per-unit costs by 10–20%, while expedited production or niche material requests (e.g., food-grade lubricants) can increase prices by 15–30%.

Lifespan of Light Load Slewing Bearings

The operational lifespan of these bearings depends on usage intensity, maintenance practices, and environmental conditions. In light-duty applications like home automation or small electronics, they can last 8–12 years with minimal upkeep. Industrial uses such as conveyor systems or robotics operating 8–12 hours daily typically see lifespans of 5–8 years with regular lubrication and load management. Harsh environments—such as outdoor solar trackers exposed to rain, dust, or temperature fluctuations—may reduce longevity to 3–5 years, even with sealed designs. Key factors for maximizing lifespan include avoiding overloading (staying below 75% of rated capacity), using compatible lubricants, and protecting against contaminants like sand or chemicals.

How to Choose the Right Light Load Slewing Bearing

Selecting the ideal bearing requires balancing technical specifications with practical considerations. Begin by calculating axial, radial, and moment loads using manufacturer guidelines or simulation tools, then choose a bearing with a 20–30% safety margin. For precision-critical tasks like optical alignment, prioritize crossed roller bearings with low backlash, while single-row ball bearings suit cost-sensitive, moderate-speed applications. Evaluate environmental conditions—stainless steel and IP65+ seals are essential for humid or dusty settings, whereas aluminum suffices for lightweight indoor systems. Verify mounting compatibility: flange-mounted bearings simplify installation in pre-drilled machinery, while hollow shafts streamline cable management. Partner with suppliers offering certifications like ISO 9001 and request load-test reports for critical applications. Finally, consider total cost of ownership—budget options may require frequent replacements, while higher-quality models offer long-term reliability.

Common Mistakes to Avoid

A frequent error is overestimating load capacity—using a light-duty bearing for even slightly heavy loads accelerates wear and leads to premature failure. Ignoring environmental protection, such as deploying unsealed bearings in dusty or wet environments, invites contamination and corrosion. Using incorrect lubricants, like generic grease instead of manufacturer-recommended types, increases friction and heat, degrading performance. Misalignment during installation strains bearings, causing uneven wear; always use alignment tools and adhere to torque specifications for bolts. Skipping maintenance schedules, such as annual lubrication or inspections, drastically shortens lifespan. Lastly, choosing solely based on price often backfires—cheaper bearings may cost significantly more in repairs if they fail prematurely.

Light Load Slewing Bearing Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.