Unmasking the Beast: The Open Housing Slewing Drive S9 Revolutionizing Heavy Machinery

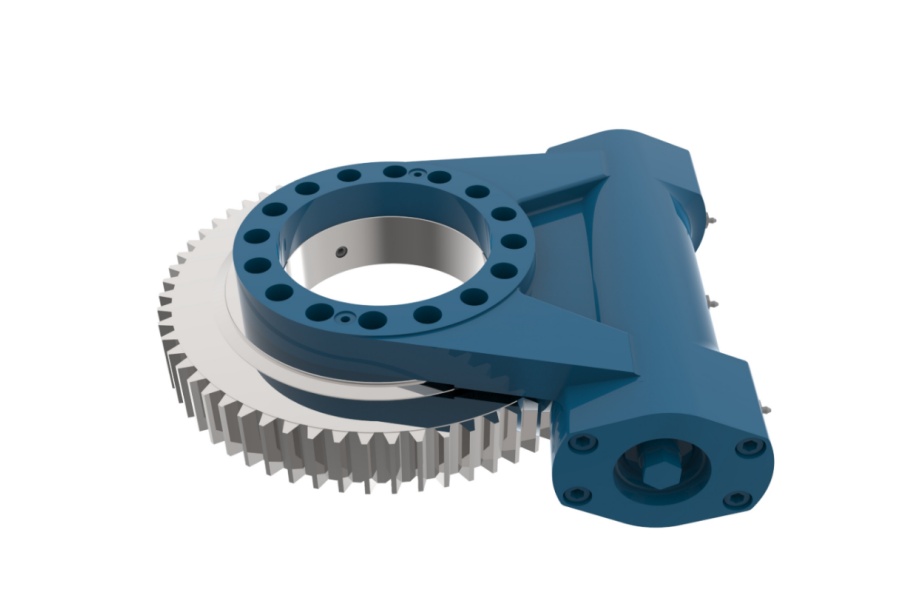

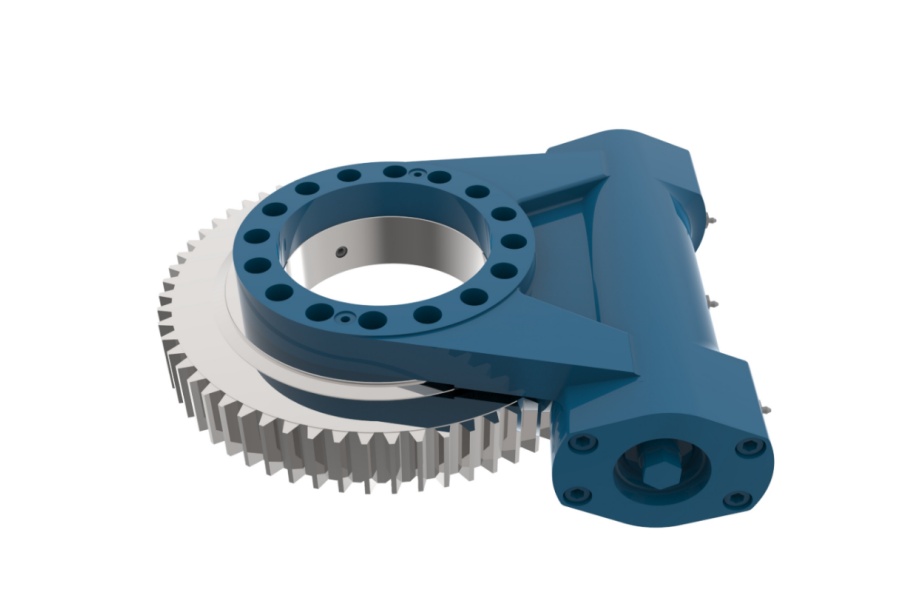

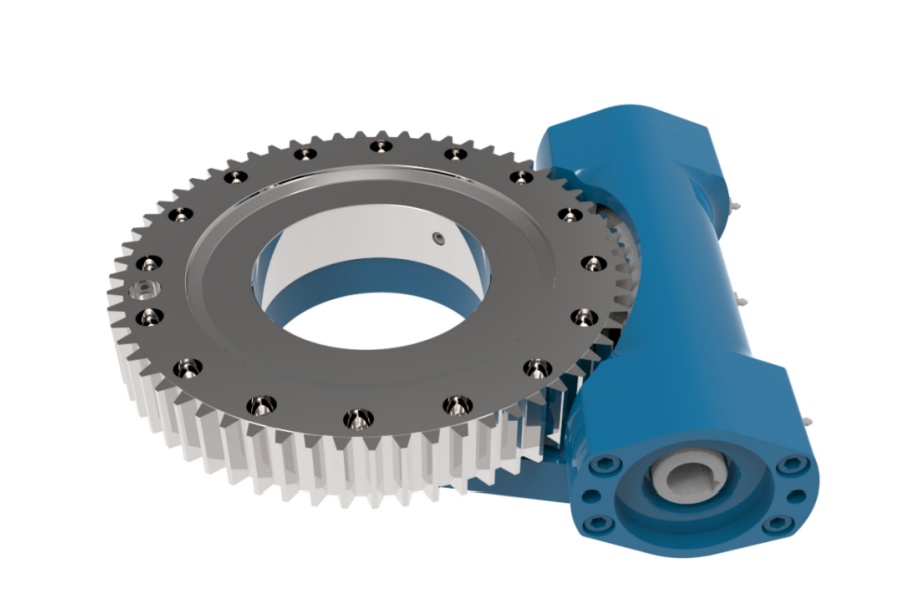

What is the Open Housing Slewing Drive S9?

The Open Housing Slewing Drive S9 is a sophisticated rotational drive mechanism characterized by its distinct, non-enclosed housing design. Unlike conventional slewing drives sealed within a rigid casing, the S9's core components – the large-diameter bearings, precision gearing (typically worm or planetary sets), and often the motor interface – are partially exposed or easily accessible. This deliberate design philosophy prioritizes unparalleled access for inspection, maintenance, and repair without requiring complete drive disassembly. Engineered for exceptional torque density and radial/axial load capacity, the S9 translates rotational input into powerful, controlled output rotation for the platform it supports, making it the backbone of applications requiring immense strength and precise movement under stress.

Shielded by Strength: S9 Drives in Shield Machine Repair

Shield machines, the titans of underground tunneling, demand absolute reliability from every component. When their slewing drives, responsible for rotating the cutting wheel assembly, fail or degrade, downtime is catastrophic. The Open Housing Slewing Drive S9 is uniquely suited for shield machine repair and refurbishment. Its open architecture allows maintenance crews unparalleled access directly to critical wear points like bearing races, gear teeth, and sealing surfaces. Inspection becomes visual and tactile, enabling rapid assessment of damage (pitting, spalling, wear, seal failure). Crucially, targeted repairs or component replacements (bearings, gears, seals) can often be performed in-situ or with minimal drive removal, drastically slashing repair time and cost compared to battling with a fully sealed unit. The S9's inherent robustness also ensures it can handle the immense cutting forces and vibrations inherent in tunneling operations post-repair.

Diagnosing the Growl: S9 Slewing Drive Noise Troubleshooting

Anomalous noises from a slewing drive are urgent warnings. The S9's open design significantly streamlines the diagnostic process. Follow this structured flow:

Isolate & Identify: Determine the type of noise (grinding, clicking, whining, rumbling) and its occurrence (continuous, intermittent, specific load/direction).

Visual Inspection (Leverage Openness): Immediately inspect exposed gear teeth for chipping, pitting, or lack of lubrication. Check accessible bearing surfaces for scoring, discoloration (overheating), or contamination ingress. Examine seals for damage or leakage paths.

Lubrication Check: Verify lubricant level, condition (presence of metal flakes, water, degradation), and correct specification. Insufficient or contaminated lube is a prime noise culprit.

Bearing Focus: Rumbling or grinding often points to bearings. Use stethoscopes or vibration analysis tools on the bearing housings where possible. Check for axial/radial play by manually rocking the driven structure.

Gear Mesh Assessment: Whining or howling under load suggests gear mesh issues (misalignment, wear, incorrect backlash). Check backlash settings per manufacturer specs. Inspect worm threads or planetary gears visually where accessible.

Mounting & Structure: Ensure the drive base and surrounding structure are rigid, free of cracks, and bolts are torqued correctly. Loose mounts can cause knocking or shifting noises.

Motor & Input: Rule out the input motor or gearbox as the noise source by temporarily disconnecting if possible. Check couplings and input shafts.

Contamination: Look for evidence of water, grit, or foreign material inside the drive through the open sections.

Document & Act: Correlate findings. Pinpointing the issue is faster with the S9's accessibility, leading to targeted corrective action – lubrication top-up/purge, seal replacement, bearing swap, or gear adjustment.

The Future is Modular: S9 and Advanced Modular Slewing Systems

The Open Housing S9 drive is a cornerstone of the burgeoning modular slewing revolution. Its design inherently supports modularity. Key components (bearing modules, gearbox cassettes, seal assemblies, even motor mounts) can be engineered as pre-assembled, pre-tested units. The open structure allows these modules to be accessed and swapped with relative ease compared to sealed drives. This modularity offers game-changing benefits: drastically reduced Mean Time To Repair (MTTR), simplified spare parts logistics (stock modules instead of entire drives), easier upgrades (swapping gear ratios), and enhanced flexibility in machine design and customization. A failed bearing module doesn't necessitate replacing the entire drive system, translating to massive operational cost savings and uptime preservation.

Uncompromising Power: Defining Features of the Open Housing S9 Drive

The S9 isn't just different; it's engineered for superiority:

Unparalleled Serviceability: The defining feature. Direct access slashes maintenance time, complexity, and cost. Visual inspection is immediate.

Extreme Load Capacity: Robust construction with large-diameter bearings and hardened, precision gearing delivers exceptional radial, axial, and moment load handling.

Enhanced Heat Dissipation: The open design allows for better airflow around critical components like bearings and gears, reducing operating temperatures and extending lubricant and component life, especially in high-duty cycles.

Optimized Lubrication Management: Easier access for lubrication checks, purges, and changes. Contaminants are also easier to spot and flush out.

Robustness & Durability: Built with high-grade materials and rigorous manufacturing standards to withstand shock loads, vibrations, and harsh environments (dust, moisture, temperature extremes).

Modularity Potential: Designed to integrate seamlessly with modular component strategies for maximum lifecycle value.

Versatile Mounting & Integration: Adaptable mounting options facilitate integration into diverse machinery designs.

Where Giants Turn: Key Applications for the Open Housing S9 Drive

The S9's blend of strength, serviceability, and reliability makes it indispensable in sectors where downtime is measured in fortunes:

Heavy Construction & Earthmoving: Excavator attachments (crushers, pulverizers, grapples), large material handlers, drilling rig bases, crane jibs requiring high moment load capacity.

Mining & Quarrying: Robust crushers, screeners, stackers, reclaimers, and large excavators operating in abrasive, high-impact environments.

Tunneling & Shield Machines: Critical for rotating cutterheads and other assemblies under immense pressure and in confined, dirty spaces demanding serviceability.

Forestry Processing: Delimbers, harvesters, and forwarders needing high torque and resilience against shock loads in demanding conditions.

Recycling & Material Handling: Heavy-duty shredders, shear handlers, and bulk material handling equipment requiring reliable rotation under extreme stress.

Renewable Energy: Foundation positioning systems for large installations, heavy-duty solar tracker drives.

Specialized Heavy Machinery: Any application demanding high rotational torque, load capacity, and ease of maintenance in challenging settings.

Investing in Rotation: Factors Influencing Open Housing S9 Drive Pricing

The cost of an Open Housing Slewing Drive S9 reflects its advanced engineering and capabilities. Key factors include:

Load Capacity: The primary driver. Drives rated for higher radial, axial, and moment loads require larger bearings, heavier structural components, and more robust gearing, significantly increasing cost.

Size & Torque Rating: Larger diameter drives handling higher input torque naturally cost more due to material volume and manufacturing complexity.

Gear Type & Ratio: Precision planetary gear sets often command a premium over worm gears. Complex or very high reduction ratios add cost.

Bearing Quality & Type: The size, precision grade (e.g., P4, P2), and type (crossed roller, triple row roller) of the main bearings are major cost factors. High-precision, large-capacity bearings are expensive.

Material Specifications: Use of high-strength, hardened, or corrosion-resistant alloys (e.g., special steels, coatings) increases material costs.

Sealing & Protection (IP Rating): While open, critical areas still need protection. Advanced sealing systems for high IP ratings (dust/water resistance) add cost. Optional hardened covers or shields also contribute.

Customization & Integration: Modifications from standard designs (special bolt patterns, interfaces, mounting lugs, integrated sensors) incur engineering and manufacturing expenses.

Manufacturing Precision & Quality Control: The level of machining accuracy, heat treatment, grinding, and rigorous QC (like 100% gear inspection) impacts price. Premium brands invest heavily here.

Brand Reputation & Certifications: Established manufacturers with proven reliability, extensive testing, and industry certifications often command a premium justified by reduced risk and longer service life.

Order Volume & Supply Chain: Economies of scale apply. Long lead times for specific components can also influence market price.

Securing Your Rotational Core: Partnering with a Premier S9 Supplier

Selecting the right supplier for Open Housing Slewing Drive S9 units is as critical as the drive itself. You need a partner offering more than just a product; you need engineering support, reliability, and global service capability. Leading suppliers in this high-performance segment distinguish themselves through:

Proven Expertise & Application Engineering: Deep understanding of heavy machinery dynamics and the ability to engineer S9 solutions tailored to specific, extreme operational demands (loads, environment, duty cycle).

Rigorous Manufacturing & Quality: State-of-the-art facilities employing precision machining, advanced heat treatment, meticulous assembly, and exhaustive testing protocols (load testing, rotational accuracy, backlash checks, seal integrity). Certifications (ISO 9001, etc.) are essential.

Uncompromising Material Selection: Sourcing only high-grade bearing steels and alloys, and partnering with top-tier bearing and gear suppliers.

Technical Support & Diagnostics: Providing expert troubleshooting support, noise analysis guidance, and proactive maintenance recommendations throughout the drive's lifecycle.

Global Support & Spare Parts Network: Ensuring rapid availability of critical spare parts and modules worldwide to minimize downtime. Comprehensive repair and refurbishment services are crucial.

Focus on Modularity & Serviceability: Designing S9 drives with modularity principles from the ground up, facilitating the quick-swap capabilities that deliver maximum uptime.

Supplier of Open Housing Slewing Drive S9

Commitment to Innovation: Continuously refining designs for enhanced performance, durability, and ease of maintenance. LYRADRIVE embodies these critical supplier attributes. With a relentless focus on engineering excellence for the most demanding applications, LYRADRIVE delivers Open Housing Slewing Drive S9 solutions built on a foundation of precision manufacturing, rigorous testing, and unparalleled commitment to customer support and machinery uptime. Their expertise ensures your rotational drive isn't just a component, but a guaranteed cornerstone of productivity. Partnering with LYRADRIVE means investing in proven rotational power designed for the long haul.