Unlocking Efficiency: The Complete Guide to Medium Duty Gear Slewing Drives for Industrial Applications

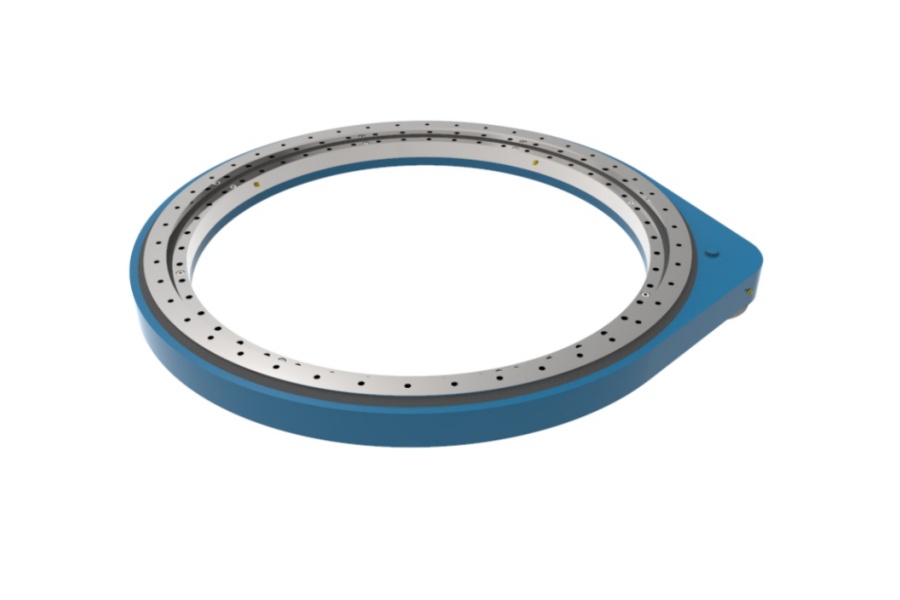

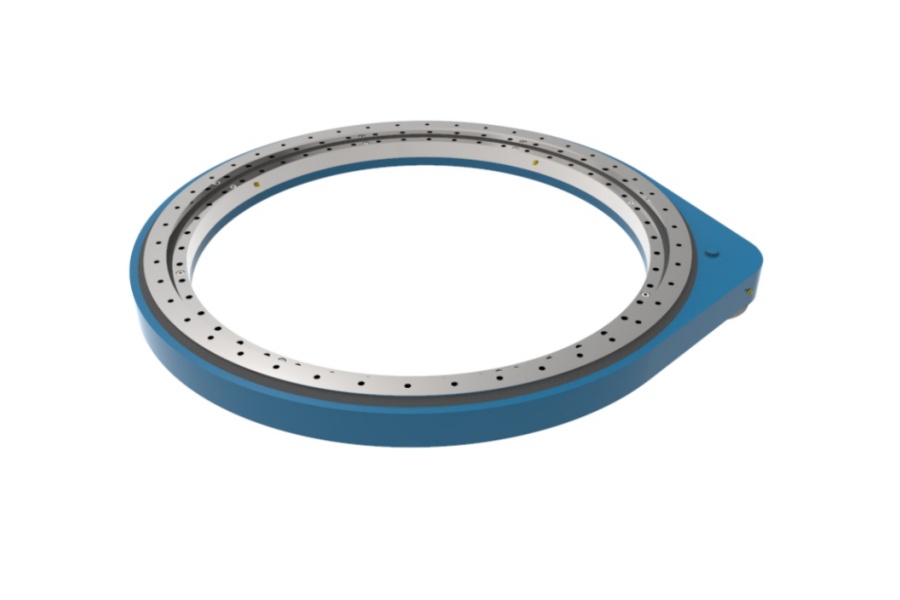

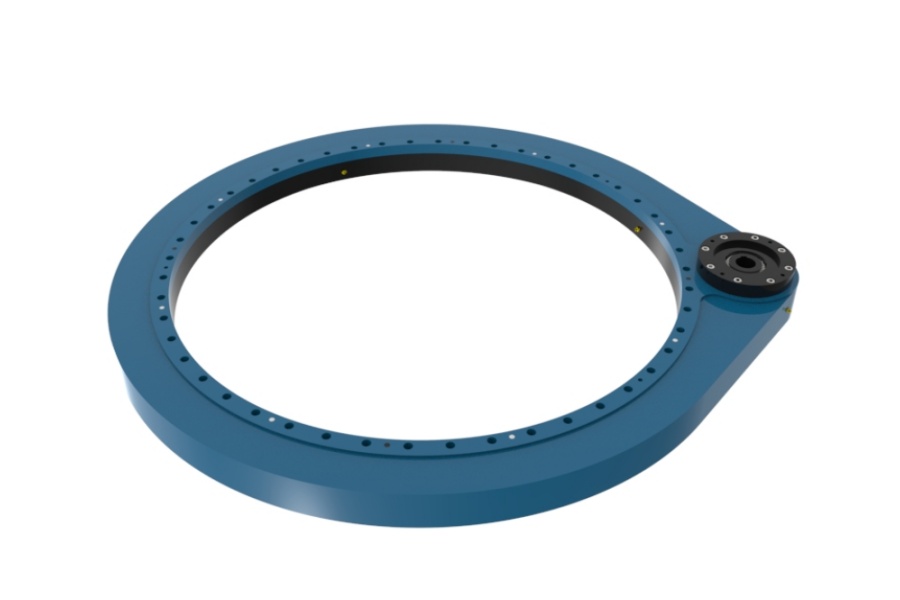

What Exactly is the Medium Duty Gear Slewing Drive SP-M 1091?

The SP-M 1091 is a specific model within a category of rotational power transmission devices known as slewing drives or slewing rings. It integrates several critical components into a compact, sealed unit: a high-quality worm gear set, a large-diameter slewing bearing (typically featuring crossed roller or ball bearings), a robust housing, and often sealing elements and preload adjustment mechanisms. The "Medium Duty" classification indicates it is engineered to handle substantial loads and torques, but is optimized for applications demanding a balance between strength, precision, and compactness, distinguishing it from larger, heavier heavy-duty units. The SP-M 1091 designation refers to its specific size, load rating, gear ratio, and mounting configuration as defined by the manufacturer, LYRADRIVE.

The Powerhouse: Understanding Heavy-Duty Industrial Turntable Drives

Heavy-duty industrial turntable drives represent the upper echelon of slewing drive technology. Engineered for the most extreme applications, these units are characterized by their massive size, exceptionally high load capacities (both axial and radial), and ability to transmit enormous output torques while resisting severe shock loads. They often feature hardened steel gears, specialized bearing arrangements (like triple-row roller bearings), reinforced housings, and advanced sealing systems. Applications demanding this level of performance include giant mining excavators, massive container cranes, heavy-lift offshore equipment, large radar installations, and significant segments of the wind turbine industry where nacelle yaw control requires immense rotational force under challenging conditions.

Medium Duty vs. Heavy Duty Slewing Drives: Choosing the Right Tool

Selecting between medium and heavy-duty slewing drives hinges on application requirements. Heavy-duty drives excel where ultimate strength and maximum torque are non-negotiable, often in massive machinery experiencing brutal loads. However, this capability comes with trade-offs: significantly larger physical dimensions, substantially higher weight, increased complexity, and a much higher price point. Medium-duty drives, like the SP-M 1091, offer a compelling alternative for a vast array of applications. They provide substantial torque and load capacity – sufficient for many industrial tasks – within a significantly more compact and lighter package. This translates to easier integration, lower material costs for supporting structures, and overall cost-effectiveness where the extreme capabilities of heavy-duty units are simply unnecessary. The SP-M 1091 occupies this crucial middle ground, delivering dependable power without excessive bulk or expense.

Standout Features of the Medium Duty Gear Slewing Drive SP-M 1091

The SP-M 1091 distinguishes itself through a combination of performance-oriented engineering and practical design. Its core strength lies in the hardened and ground worm gear set, meticulously manufactured to ensure smooth operation, high efficiency, and exceptional durability under continuous use. The integrated slewing bearing provides high rigidity and precision rotation, handling combined axial, radial, and moment loads effectively. A key feature is its compact footprint; the SP-M 1091 delivers impressive torque density relative to its size, making it ideal for space-constrained installations. Robust sealing protects critical internal components from dust, moisture, and contaminants, significantly extending service life even in harsh environments. The drive is engineered for low maintenance requirements, contributing to lower total operating costs. Furthermore, it often offers mounting flexibility and can be configured with various gear ratios to precisely match speed and torque requirements. Optional features like integrated motors, brakes, or position sensors enhance its versatility for sophisticated automation tasks.

Where the SP-M 1091 Excels: Diverse Industrial Applications

The versatility and robust performance of the SP-M 1091 make it indispensable across numerous sectors. In material handling, it powers industrial turntables for positioning heavy pallets, machinery, and workpieces, as well as operating robust indexing tables and sophisticated robotic welding positioners. The solar energy industry relies on it for precise azimuth and elevation tracking in mid-sized solar tracker systems, maximizing energy capture. Within construction and agriculture, it provides reliable rotation for crane jibs, concrete mixer drums, sprayer booms, and specialized drilling equipment attachments. Manufacturing utilizes it in automated assembly lines, packaging machinery requiring precise rotational indexing, and large fixture positioning. Additionally, it finds roles in stage and entertainment technology for moving platforms and lighting rigs, antenna positioning systems, medical imaging equipment rotation, and specialized machinery across diverse fields like forestry and recycling. Its adaptability is a key strength.

Factors Influencing the Price of the Medium Duty Gear Slewing Drive SP-M 1091

The cost of an SP-M 1091 unit is not fixed and depends on several key variables. The most fundamental is the specific load capacity and torque rating required; drives engineered for higher loads naturally command a higher price due to enhanced materials and manufacturing processes. The chosen gear ratio impacts cost, with higher reduction ratios often being more complex to produce. Material selection plays a significant role; housings and gears made from higher-grade alloys or subjected to advanced heat treatments increase durability but also cost. Manufacturing precision is paramount; drives built to tighter tolerances for smoother operation and higher efficiency require more sophisticated machining, impacting price. The inclusion of optional features like integrated high-efficiency motors (brushless DC, servo), electromagnetic brakes, absolute or incremental encoders for precise positioning feedback, special high-temperature or food-grade seals, or custom lubrication significantly adds to the base cost. Order volume is a critical factor; bulk purchases typically benefit from economies of scale, reducing the unit price. Finally, the required lead time can influence cost, with expedited manufacturing or delivery often incurring premiums.

Supplier of SP-M 1091

When sourcing a critical component like the SP-M 1091, choosing the right supplier is paramount. LYRADRIVE has established itself as a leading global manufacturer specializing in high-performance slewing drives for demanding industrial applications. They bring deep engineering expertise to the table, offering not just standardized products but also significant customization capabilities to tailor the SP-M 1091 (or other models) to your exact requirements. LYRADRIVE emphasizes stringent quality control throughout the manufacturing process, ensuring each drive meets rigorous performance and durability standards. Their commitment extends beyond the sale, providing comprehensive technical support for selection, integration, and troubleshooting. Furthermore, LYRADRIVE often maintains readily available stock or efficient production lines for popular models like the SP-M 1091, helping to minimize lead times and keep your projects on schedule. Partnering with LYRADRIVE means accessing reliable technology backed by industry knowledge and dedicated support.

The Strategic Advantage of Medium Duty Performance

The Medium Duty Gear Slewing Drive SP-M 1091 represents an optimal engineering solution for a vast spectrum of industrial challenges. It masterfully bridges the gap between the compactness of lighter units and the overwhelming power of heavy-duty drives. By delivering substantial torque, reliable load handling, and precise rotational control within a space-efficient and cost-effective package, the SP-M 1091 empowers designers and engineers. Its versatility across industries – from automating factory floors and harnessing solar energy to moving materials and building infrastructure – underscores its fundamental role in modern machinery. Understanding its capabilities, features, and the factors influencing its specification and cost allows for informed decision-making. For applications demanding robust performance without the footprint or expense of heavy-duty alternatives, the SP-M 1091 stands as a proven, efficient, and strategic choice. Partnering with an experienced manufacturer like LYRADRIVE ensures access to this technology, backed by the engineering support and quality assurance necessary for long-term operational success. Selecting the SP-M 1091 is an investment in reliable motion, enhanced productivity, and optimized machine design.