Three Row Roller Slewing Bearings Heavy Load Rotation Solution

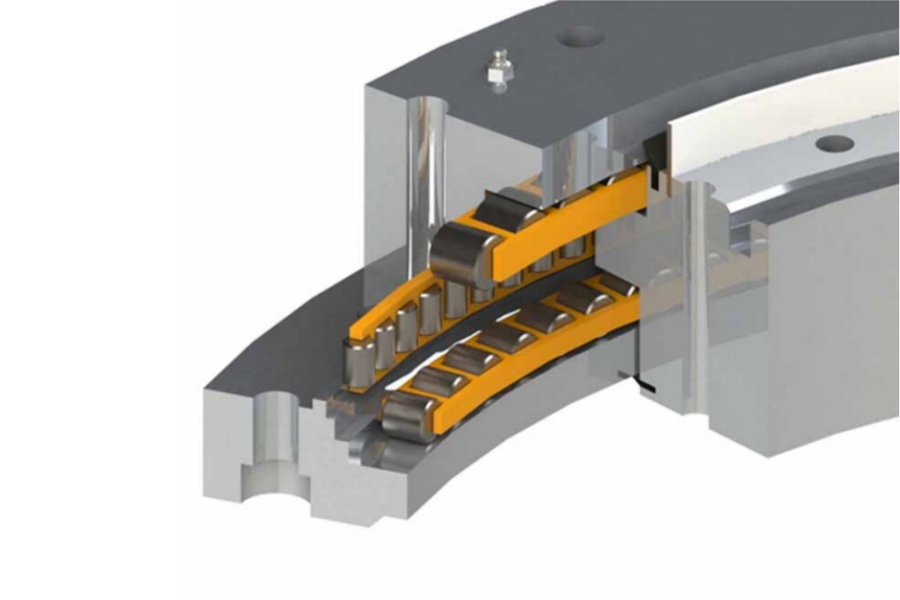

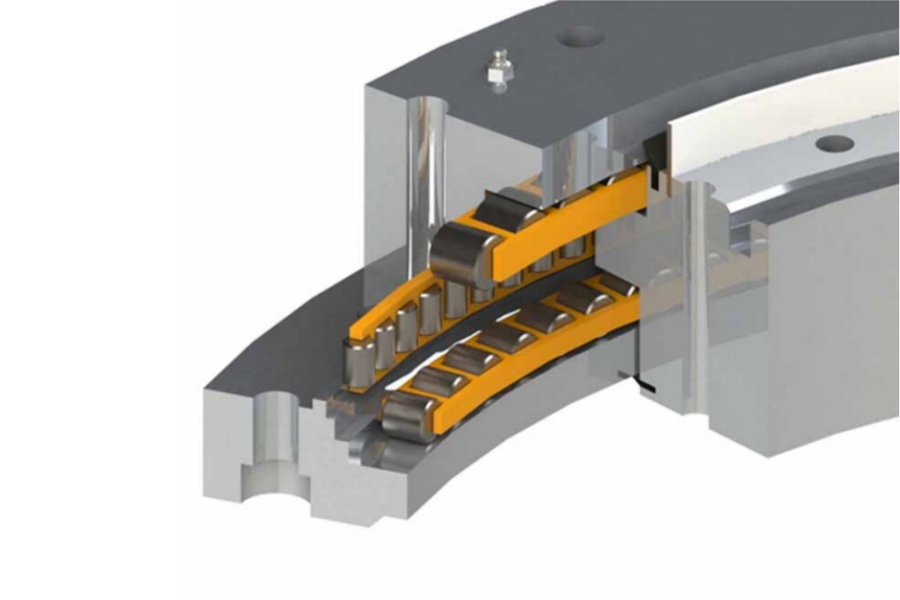

What is Three Row Roller Slewing Bearing

Three Row Roller Slewing Bearing is a precision-engineered rotational assembly consisting of an inner ring, outer ring, three independent rows of cylindrical rollers, high-strength cages or spacers, and advanced sealing systems. This specialized configuration dedicates two roller rows exclusively to handling axial forces while the third row manages radial loads. The raceways feature meticulously machined flat profiles hardened through intermediate frequency induction treatment to achieve surface hardness of HRC 55-60 with case depths of 3-6 mm. Unlike point-contact ball bearings, this design establishes full-line contact between rollers and raceways, creating unparalleled load distribution capabilities. Integrated mounting holes on both rings ensure secure installation onto heavy equipment structures. Precision-engineered cages maintain exact roller spacing and alignment, guaranteeing smooth rotation even under maximum operational stress.

Optimizing Gear Machining Efficiency

Enhancing gear production efficiency for Three Row Roller Slewing Bearings requires strategic approaches:

Implement multi-axis CNC hobbing machines with simultaneous cutting operations, reducing cycle times by 30-40%

Utilize CAM software for optimized toolpaths that minimize non-cutting movements

Employ high-speed machining with advanced carbide or ceramic cutting tools

Integrate induction hardening directly into production lines to eliminate secondary handling

Incorporate automated inspection systems like CMM or laser scanners for real-time quality control

Adopt sensor-based tool monitoring to predict replacement timing

Implement modular fixturing systems for rapid changeovers between production batches

Energy Efficiency Advantages of Three Row Roller Slewing Bearings

Three Row Roller Slewing Bearings deliver exceptional energy efficiency through innovative engineering. The full-line contact between cylindrical rollers and flat raceways reduces contact pressure by 65-70% compared to ball bearings, significantly lowering rolling friction torque. Optimized raceway geometry minimizes roller skidding and slippage, decreasing parasitic energy losses. Precision hardening maintains surface integrity throughout the bearing's operational life, preventing friction increases from surface degradation. The rigid structural design limits elastic deformation under heavy loads, reducing hysteresis power losses. Advanced sealing technologies maintain consistent lubrication integrity, preventing drag from contamination. Collectively, these features reduce operational energy consumption by 15-25% compared to equivalently sized ball-type slew bearings, particularly in high-load, low-speed applications.

Distinctive Technical Features of Three Row Roller Slewing Bearings

Record-Breaking Load Capacity: Triple-row configuration handles extreme forces (45,000 kN axial/15,000 kN radial)

Optimized Stress Distribution: Dedicated load paths eliminate cross-load interference

Superior Structural Rigidity: Full-line contact provides 200-300% greater stiffness than ball bearings

Precision Manufacturing: Roller diameter tolerances within ±0.005 mm and raceway flatness of 0.01 mm/m

Robust Construction: Forged alloy steel rings with through-hardening capabilities

Configuration Versatility: Non-geared, external gear, and internal gear variants available

Specialized Gear Hardening: Customizable tooth hardening including root-to-flank treatment

Extended Service Life: Minimum L10 rating exceeding 100,000 operational hours

Critical Industrial Applications of Three Row Roller Slewing Bearings

Mining Mega-Machines: Bucket wheel excavators (14,000+ ton/hour capacity), stackers, and reclaimers

Heavy Lift Crane Systems: Ship-to-shore cranes (2,500+ ton capacity), floating cranes, derricks

Steel Production: Ladle turrets, continuous casting machines, slab handling equipment

Port Infrastructure: Super-post-Panamax container cranes, bulk material handlers

Energy Sector: Jack-up rig positioning systems, heavy-lift vessel cranes

Specialized Engineering: Tunnel boring machines, radar platforms, launch pad structures

Key Pricing Factors of Three Row Roller Slewing Bearings

Material Specifications: Premium 42CrMo4/50Mn alloy steel versus standard carbon steel

Dimensional Scale: Bearings exceeding 5-meter diameter incur exponential cost increases

Precision Requirements: AGMA 14/ISO 1328 gear standards versus commercial tolerances

Heat Treatment Complexity: Integrated tooth root hardening adds 25-30% to base cost

Custom Engineering: Non-standard mounting interfaces or specialized sealing systems

Gear Configuration: Internal gears typically cost 15-20% more than external equivalents

Roller Quality: Precision-ground rollers (DIN 5401 Class 2) versus standard grade

Certification Compliance: Third-party inspection to EN 10204 3.1/3.2 specifications

Protective Coatings: Marine-grade corrosion-resistant treatments

Production Economics: Setup cost allocation for small-batch manufacturing

Supplier of Three Row Roller Slewing Bearings

LYRADRIVE stands as a global leader in manufacturing Three Row Roller Slewing Bearings engineered to ISO 9001 and DIN EN 15001-6 standards. Their technical expertise covers custom design solutions for bearings up to 8-meter diameter and 100-ton capacity, serving mining, port, and heavy construction industries worldwide. LYRADRIVE's integrated approach combines precision machining with specialized heat treatment and rigorous testing protocols, delivering complete rotation solutions backed by comprehensive technical support from installation through lifecycle maintenance.