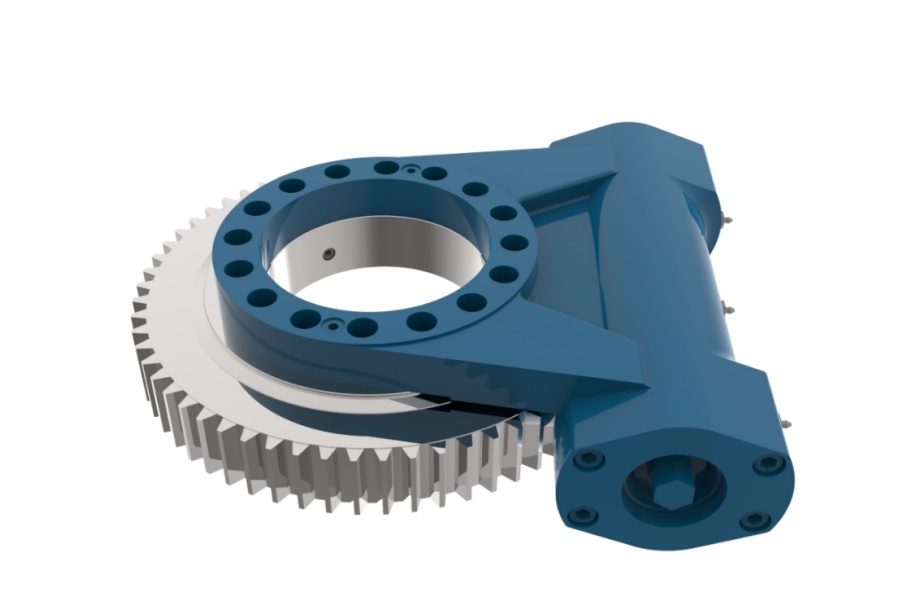

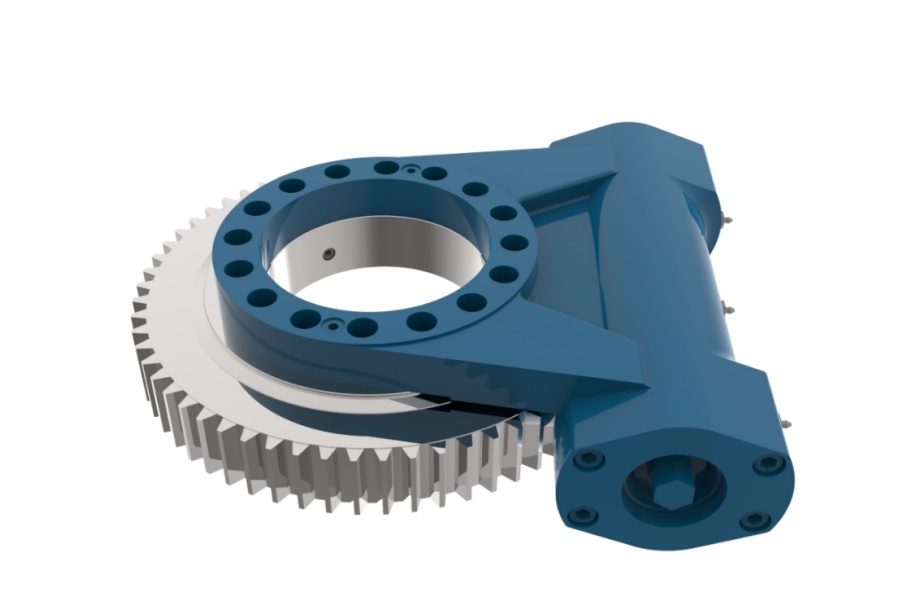

The Open Housing Slewing Drive S9 Power and Precision in a Modular Design

What is Open Housing Slew Drive S9

Open Housing Slew Drive S9 is a compact, high-performance rotary actuator specifically engineered to provide smooth, precise, and powerful rotational motion around a vertical axis. Its defining characteristic is the exposed structural framework of its housing, which deliberately leaves the internal gearing and critical components accessible. This deliberate design choice fundamentally differentiates it from traditional enclosed slewing drives, prioritizing ease of maintenance, inspection, and adaptability during integration into complex machinery. The S9 integrates a precision worm gear set for high reduction and self-locking capability directly with a robust split-type slewing ring bearing, creating a unified unit optimized for handling combined loads (axial, radial, and moment) efficiently. Engineered for demanding industrial applications, it delivers exceptional torque output and load capacity relative to its compact size and weight.

Understanding Split-Type Slewing Rings

The core innovation enabling the unique advantages of the S9 lies in its utilization of a split-type slewing ring bearing. Unlike conventional single-piece slewing rings, a split-type bearing is manufactured in two or more precision-machined segments. These segments are meticulously engineered to align perfectly when assembled, forming a complete bearing raceway without compromising structural integrity or load-handling capability. This segmentation is revolutionary for installation and maintenance scenarios. It eliminates the absolute requirement to disassemble large sections of machinery or thread the entire drive assembly over the end of a shaft for mounting. Instead, the split bearing segments can be positioned around an existing shaft or structural element and then securely bolted together, significantly simplifying integration, especially in retrofit applications or confined spaces. This inherent flexibility drastically reduces downtime during installation or bearing replacement, making the S9 exceptionally service-friendly.

S9 Technical Parameters: Engineered for Heavy-Duty Performance

The Open Housing Slew Drive S9 boasts an impressive set of technical specifications, reflecting its design for demanding operational environments. Its performance is characterized by high torque ratings and substantial load capacities:

Output Torque: 6.5 kN.m - This substantial torque enables the S9 to drive heavily loaded platforms or structures effectively.

Tilting Moment Torque: 33.9 kN.m - A critical rating indicating the drive's ability to resist overturning forces acting perpendicular to the axis of rotation.

Holding Torque: 38.7 kN.m - This high static holding torque ensures excellent resistance to back-driving, providing inherent braking and position stability without requiring an external brake in many applications, crucial for safety and precision.

Static Axial Rating: 338 kN - The maximum axial (thrust) load the bearing can support without permanent deformation when stationary.

Static Radial Rating: 135 kN - The maximum radial (side) load the bearing can support without permanent deformation when stationary.

Dynamic Axial Rating: 81 kN - The maximum continuous axial load the bearing can support while rotating under normal operating conditions.

Dynamic Radial Rating: 71 kN - The maximum continuous radial load the bearing can support while rotating under normal operating conditions.

Gear Ratio: 61:1 - This high reduction ratio provides significant mechanical advantage, allowing a relatively compact motor to generate high output torque while enabling precise speed control.

Tracking Precision: ≤ 0.17° - Indicates the drive's high positional accuracy and repeatability, essential for applications requiring fine pointing or controlled movement.

Weight: 39 kg - Remarkably lightweight for its performance capabilities, contributing to overall system weight savings and ease of handling.

These parameters clearly position the S9 as a solution for applications requiring significant power transmission, high load support, and reliable positioning in a relatively compact and lightweight package.

Open Housing Slew Drive S9 Characteristics: Defining Advantages

The S9's unique design translates into several compelling characteristics that offer tangible benefits over traditional enclosed slewing drives:

Unmatched Accessibility & Serviceability: The open-frame design is the standout feature. It allows direct visual inspection of gears, the worm/worm wheel interface, and bearing surfaces without disassembly. Lubrication points are readily accessible, simplifying routine maintenance. Crucially, critical components like the worm shaft or bearing segments can often be replaced without removing the entire unit from the host machine, drastically reducing downtime and maintenance costs.

Simplified Installation & Retrofit Capability: Primarily enabled by the split-type bearing, the S9 can be installed around existing shafts or structural members. This eliminates the need for costly and time-consuming disassembly of surrounding equipment or designing structures specifically for end-shaft mounting, offering immense flexibility for new designs and retrofitting existing machinery.

Robust Load Handling: Despite the open design, the S9 maintains exceptional structural integrity. It is engineered to handle significant combined loads – axial, radial, and tilting moments – simultaneously, as evidenced by its high static and dynamic load ratings and substantial tilting moment capacity.

High Precision & Stability: With tracking precision ≤ 0.17° and a high 61:1 gear ratio, the S9 delivers accurate and repeatable positioning. The worm gear mechanism provides inherent self-locking (especially evident in the high holding torque), ensuring stable positioning without external braking under typical loads.

Power Density: Delivering up to 6.5 kN.m of output torque while weighing only 39 kg, the S9 offers an excellent power-to-weight ratio, making it efficient for weight-sensitive applications.

Durability: Designed for industrial environments, the S9 utilizes high-quality materials and precision manufacturing to ensure long service life under demanding conditions. The accessible design also facilitates timely maintenance, further extending operational lifespan.

Thermal Management: The open structure allows for better heat dissipation compared to fully enclosed drives, potentially improving performance consistency and longevity, especially in high-duty-cycle applications.

Open Housing Slew Drive S9 Applications: Versatility in Motion

The combination of power, precision, flexibility, and ease of maintenance makes the Open Housing Slew Drive S9 suitable for a diverse range of demanding applications across numerous industries:

Solar Tracking Systems: Ideal for single-axis and dual-axis solar trackers, providing the torque needed to precisely orient large solar panels or parabolic troughs towards the sun throughout the day, maximizing energy capture. The precision and holding torque are critical here.

Material Handling & Cranes: Used in crane jib rotation, manipulator arms, and positioners, offering the strength to handle heavy loads and the stability for precise positioning. The split bearing design simplifies mounting on crane structures.

Construction & Heavy Equipment: Applicable in equipment like compactors, drilling rig attachments, and lifting devices requiring robust rotational movement under heavy loads and in harsh environments.

Wind Energy: Suitable for auxiliary systems within wind turbines, such as yaw drive backups or maintenance platform positioning, where reliability and serviceability are paramount.

Robotics & Automation: Provides precise rotary motion for robotic arms, welding positioners, indexing tables, and automated assembly lines where accuracy, repeatability, and compact size are valuable.

Medical & Imaging Equipment: Used in sophisticated diagnostic and therapeutic machines (like CT scanners or radiation therapy devices - where applicable based on precision needs) requiring smooth, precise, and stable rotation.

Satellite Communication & Radar: Enables precise positioning and tracking of satellite dishes and radar antennas, leveraging its high accuracy and stability.

Stage & Entertainment Technology: Powers the smooth and controlled rotation of lighting trusses, video screens, and performance platforms in theaters and event venues.

Agricultural Machinery: Used in large irrigation systems or specialized harvesting equipment requiring reliable rotational movement in outdoor conditions.

The S9's open design and split bearing are particularly advantageous in applications where space is constrained, maintenance access is difficult, retrofitting is necessary, or frequent inspection is required.

Factors Influencing Open Housing Slew Drive S9 Price

The cost of an Open Housing Slew Drive S9 is not fixed and can vary based on several key factors:

Order Volume: Like most industrial components, purchasing larger quantities typically results in significant per-unit cost reductions due to economies of scale in manufacturing and logistics.

Customization: While the S9 is a standard model, modifications can drive up costs. Examples include special coatings (e.g., corrosion resistance for marine environments), custom mounting flanges or shaft configurations, specific sealing solutions for extreme environments, unique lubrication requirements, or special material certifications.

Material Specifications: The base price assumes standard high-quality materials. Opting for premium alloys (e.g., for enhanced strength or corrosion resistance) or specialized heat treatments will increase the price.

Precision Requirements: While the S9 is inherently precise, achieving ultra-tight tolerances beyond the standard ≤0.17° tracking precision requires additional manufacturing steps and quality control, adding to the cost.

Gear Ratio Variations: While 61:1 is standard, if alternative ratios were offered to suit specific speed/torque needs, they might carry different price points based on manufacturing complexity.

Bearing Options: Variations in the split bearing design, such as different sealing systems, pre-load levels, or internal raceway treatments, can affect cost.

Geographic Market & Logistics: Manufacturing location, shipping distances, import duties, and local market dynamics influence the final landed cost for the buyer.

Supplier Value-Added Services: Technical support levels, design assistance, warranty terms, lead times, and after-sales service capabilities can be reflected in the pricing structure of different suppliers.

Supplier of Open Housing Slew Drive S9

For engineers and procurement specialists seeking a reliable source for the Open Housing Slew Drive S9, LYRADRIVE stands as a dedicated manufacturer specializing in slewing drive technology. Leveraging expertise in precision gearing and bearing integration, LYRADRIVE focuses on delivering robust and innovative solutions like the S9, designed to meet the rigorous demands of industrial applications. The company emphasizes performance, durability, and the unique serviceability advantages offered by the open housing and split-ring design. LYRADRIVE typically provides comprehensive technical specifications, supports integration queries, and offers manufacturing capabilities that can potentially accommodate specific customization needs while supplying the standard S9 model to the global market. Their focus is on delivering a critical motion component that enhances machine design flexibility and operational efficiency.