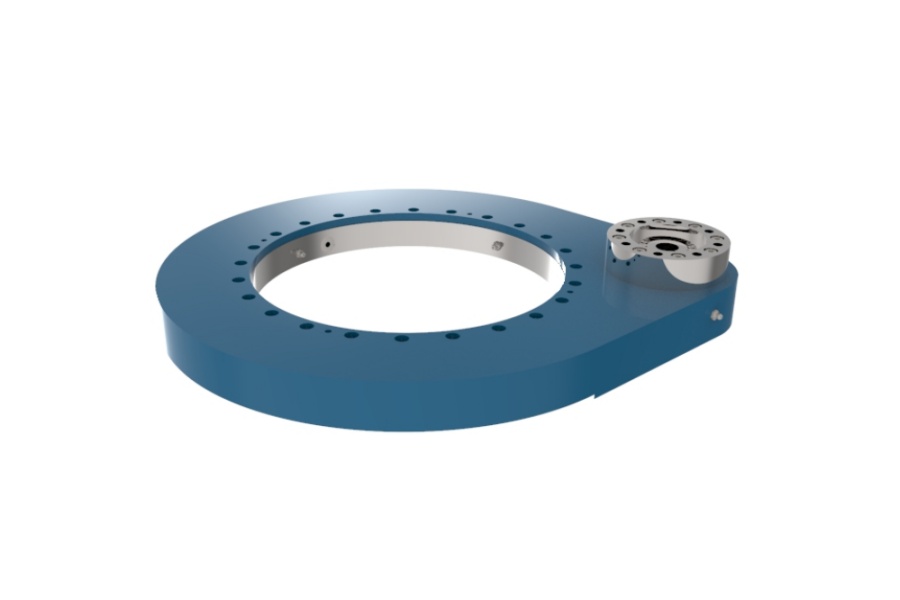

The Indestructible Core: Unveiling the SP-H 0455 Heavy Duty Gear Slewing Drive for Extreme Applications

What is the Heavy Duty Gear Slewing Drive SP-H 0455?

The SP-H 0455 represents the pinnacle of robust rotational power transmission. It's a precision-engineered, large-bore slewing drive designed explicitly for applications demanding exceptional strength, durability, and resilience against extreme forces. Unlike conventional slewing drives, the SP-H 0455 integrates a hardened, precision-ground helical gear system within a massively reinforced housing, creating a compact yet immensely powerful unit capable of handling immense axial, radial, and moment loads simultaneously. Its core function is to provide controlled, high-torque rotation for massive structures or equipment under the most severe operating conditions, ensuring reliable performance where failure is not an option. This drive is the solution for industries pushing the boundaries of mechanical stress.

Understanding the Heavy Duty Slewing Drive SP-H Series

The SP-H series stands as LYRADRIVE's flagship line for applications exceeding the capabilities of standard industrial drives. These drives are defined by their oversized, high-strength alloy steel construction, incorporating critical design enhancements. Key hallmarks include significantly increased gear module sizes for superior tooth strength, optimized bearing arrangements utilizing the largest possible rolling elements, and housings machined from solid forgings or heavy castings to resist deformation. The SP-H series employs advanced heat treatment processes, like carburizing and induction hardening, to achieve exceptional surface hardness and deep case depths on all critical wear surfaces. Premium sealing systems, often multi-layered and utilizing specialized materials, are standard to combat ingress of contaminants like dust, water, or abrasive particles, even under high-pressure washdowns. The series is designed around modularity, allowing precise configuration of gear ratios, motor flanges, mounting patterns, and sealing options to match specific application demands without compromising the core heavy-duty integrity.

Selecting a Slew Drive for High Shock Load Applications

Choosing the right slewing drive for environments plagued by sudden, intense impacts – high shock loads – is critical and requires specialized engineering. Standard drives risk catastrophic gear tooth fracture, bearing brinelling (permanent denting), housing cracks, or seal failure under such conditions. The SP-H 0455 is engineered specifically for this challenge. Its selection hinges on several non-negotiable factors. First, the gear design must prioritize impact resistance; helical gears offer smoother engagement and higher load sharing than worm gears, while hardened, precision-ground teeth with optimized profiles minimize stress concentrations. Second, bearing selection is paramount. Oversized, preloaded tapered roller bearings are typically essential in the SP-H series to handle combined loads and resist brinelling caused by shock. Third, structural rigidity is crucial; the housing must be massively reinforced with robust ribbing and thick walls to absorb energy without flexing or cracking. Fourth, internal clearances must be meticulously controlled and preloads carefully calculated to prevent damaging movement during impact events. Finally, material quality and advanced heat treatment processes ensure components possess the necessary toughness and fatigue strength to withstand repeated shocks over a long service life. The SP-H 0455 embodies these principles, making it a primary candidate for shock-intensive roles.

Unmatched Features of the Heavy Duty Gear Slewing Drive SP-H 0455

The SP-H 0455 isn't just heavy-duty; it's engineered for extremes. Its defining features translate directly into unparalleled reliability. At its heart lies a large-diameter, helical gear set manufactured from high-grade alloy steel, subjected to deep carburizing, hardening, and precision grinding. This process creates gears with exceptional surface hardness (typically 58-62 HRC) and a tough core, maximizing resistance to wear, pitting, and shock-induced fracture. The drive utilizes oversized, preloaded tapered roller bearings specifically chosen for their superior capacity to manage the complex combination of axial, radial, and moment loads encountered in heavy machinery, significantly enhancing stability and lifespan under shock. The housing is a monolithic structure, often CNC-machined from a solid forging or high-integrity casting, featuring substantial wall thicknesses and strategic ribbing. This design ensures minimal deflection under maximum load, protecting internal components and maintaining precise gear meshing. Triple-labyrinth seals, often combined with high-performance radial shaft seals and optional grease purge ports, create an exceptionally effective barrier against the ingress of water, dust, mud, and other abrasive contaminants, even in submerged or high-pressure cleaning scenarios. Standard inclusion of hardened, ground, and precisely fitted wear rings protects critical sealing surfaces. High-viscosity, extreme pressure grease is factory-filled for long-lasting lubrication. Robust integrated mounting flanges with numerous high-strength bolts ensure secure attachment to supporting structures. Optional features like integrated hydraulic motors, custom gear ratios, specialized coating (e.g., corrosion protection for marine environments), and integrated position sensors further enhance its versatility for mission-critical tasks.

Demanding Applications for the SP-H 0455 Heavy Duty Slewing Drive

The SP-H 0455 thrives where others falter, powering critical rotation in the world's toughest industries. In heavy crane applications, it provides the slewing motion for lattice boom crawler cranes, heavy-duty offshore cranes, and large pedestal cranes handling massive loads, often experiencing dynamic shock during lifting or sudden stops. Within the mining sector, it drives the slew function of massive excavators, bucket wheel reclaimers, stackers, and heavy-duty material handling shuttles, constantly battling abrasive dust, vibration, and impact loads from digging or dumping. For renewable energy, it forms the robust core of pitch and yaw drives for the largest multi-megawatt wind turbines, enduring constant weather extremes, gravitational forces, and dynamic wind gusts. The drive is indispensable in tunnel boring machines (TBMs), providing precise rotational control for the cutterhead under immense pressure and vibration deep underground. Heavy-duty industrial manipulators, robotic welding positioners handling massive components, and large radar or communication antenna platforms subject to wind loads also rely on the SP-H 0455's unwavering performance. Military applications, such as missile launcher platforms and heavy weapon system turrets, demand the absolute reliability and shock resistance this drive delivers. Essentially, any application involving massive weights, high inertia, unpredictable forces, or operation in severe, contaminant-rich environments is a prime candidate for the SP-H 0455.

Factors Influencing the Price of the Heavy Duty Gear Slewing Drive SP-H 0455

The SP-H 0455 represents a significant investment, reflecting its exceptional engineering and construction. Several key factors drive its price point. The sheer volume and quality of materials used are substantial; high-grade alloy steel forgings/castings for the housing and gears, large quantities of specialized bearing steel, and premium sealing components form the bulk of the cost. The extensive and precise machining required – CNC milling, turning, grinding of gears and critical surfaces – is complex and time-consuming, contributing significantly to the manufacturing expense. Advanced heat treatment processes like carburizing, hardening, and tempering are energy-intensive and require strict quality control, adding cost. The high-quality, large-diameter tapered roller bearings themselves represent a major component cost. Any customization dramatically impacts price; deviations from standard configurations, such as non-standard gear ratios, unique motor flanges (hydraulic, electric), special mounting patterns, custom shaft extensions, integrated encoders or brakes, specialized coatings (e.g., offshore-grade corrosion protection), or bespoke sealing solutions require additional engineering and manufacturing steps. Order volume plays a role, with larger quantities potentially benefiting from economies of scale. Finally, stringent quality assurance procedures, including rigorous testing of materials, sub-components, and the final assembled drive (often involving load testing and run-in), are essential for reliability and add to the overall cost. The price reflects the drive's capability to deliver reliable performance in the most punishing applications, minimizing costly downtime and replacements.

Supplier of SP-H 0455

When mission-critical rotation demands the ultimate in strength and reliability, LYRADRIVE stands as the engineering partner of choice. We specialize in the design, manufacture, and supply of high-performance slewing drives, with the SP-H series, including the flagship SP-H 0455, being a cornerstone of our offering. LYRADRIVE's expertise lies in understanding the extreme demands placed on heavy machinery. Our engineering team works closely with clients to precisely define application requirements – loads, speeds, environmental conditions, shock profiles, and space constraints. This deep application knowledge allows us to configure the SP-H 0455 optimally or even design custom variations to meet unique challenges. Manufacturing takes place in state-of-the-art facilities utilizing advanced CNC machining, strict quality control protocols (often exceeding industry standards), and rigorous testing procedures to ensure every drive leaving our factory meets the highest levels of performance and durability. Beyond supply, LYRADRIVE provides comprehensive technical support, from initial selection and integration guidance to maintenance recommendations and global after-sales service. We understand that downtime is unacceptable in heavy industries, and our commitment is to deliver not just a component, but a guarantee of robust, reliable rotational motion. Choosing LYRADRIVE means partnering with specialists dedicated to pushing the boundaries of slewing drive technology for the world's most demanding applications.

Investing in Unshakeable Performance

The Heavy Duty Gear Slewing Drive SP-H 0455 is not merely a component; it's an engineered solution for operational certainty in the face of extreme forces. It embodies the principles of maximum material integrity, precision manufacturing, and robust design necessary to withstand shock loads, relentless vibration, and harsh environments that would quickly destroy lesser drives. From enabling the massive lifting power of cranes and excavators to ensuring the precise positioning of wind turbines under gale-force winds, the SP-H 0455 delivers unwavering performance where it matters most. Its price reflects the premium materials, advanced processes, and engineering rigor invested in creating a product built for longevity and minimal lifecycle cost through reduced downtime and maintenance. For engineers and project managers specifying equipment for the most challenging industrial, mining, energy, or defense applications, the SP-H 0455 represents the benchmark in heavy-duty slewing technology – the indestructible core that keeps critical operations turning, reliably and powerfully, day after punishing day. When failure is not an option, the choice is clear. Partner with experts who understand extreme demands to specify the drive engineered to conquer them