The Application of Slew Drives in Welding Positioners

What is a Slew Drive

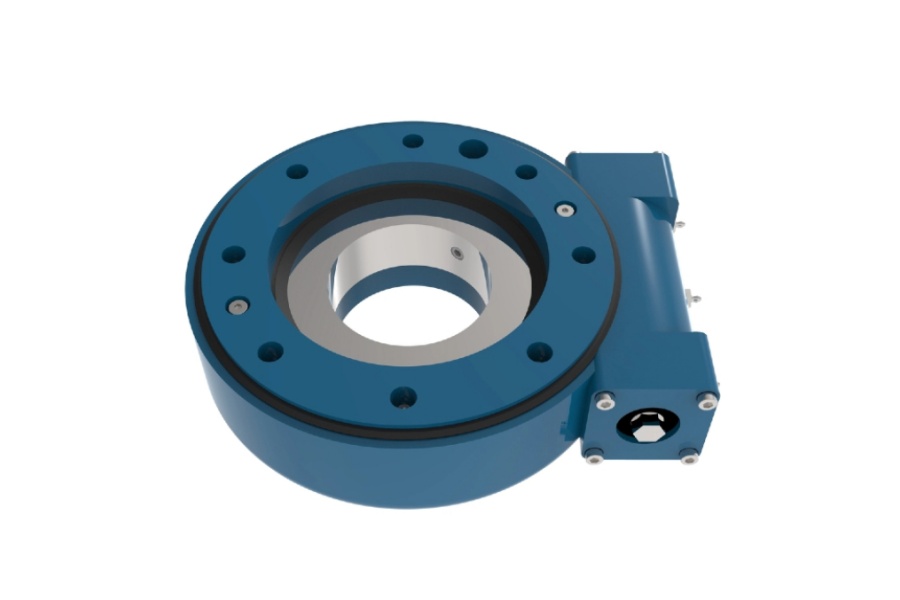

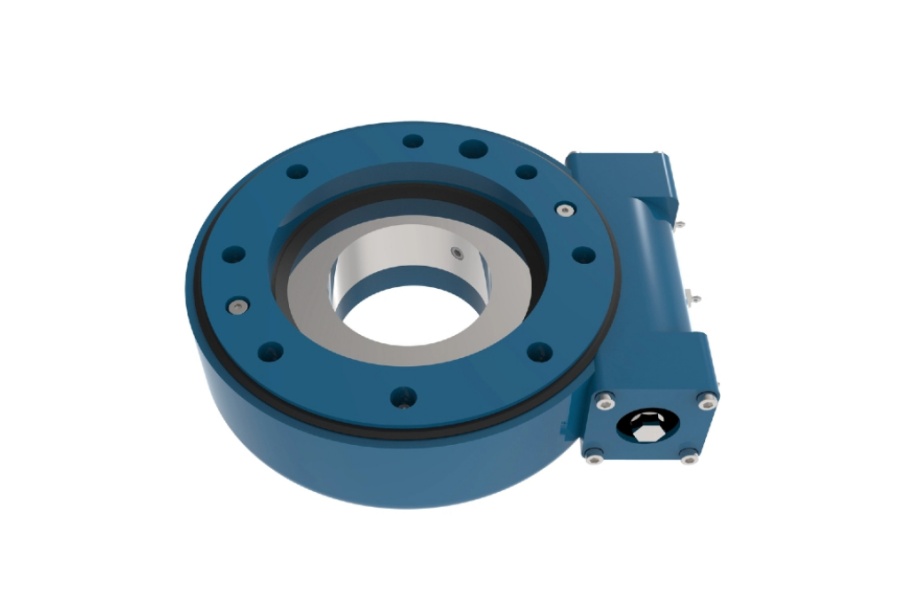

A Slew Drive is an integrated power transmission and rotational system that combines a slewing bearing with a gearbox (typically worm gear or planetary gear) and a mounting structure into a single compact unit. Its primary function is to facilitate controlled rotational movement under heavy loads with high torque output and exceptional stability. The core mechanism involves a central gear set that drives the rotation of the bearing's raceway, converting input power from an electric, hydraulic, or pneumatic motor into a slow-speed, high-torque output rotation. This integrated design provides significant advantages over traditional custom-built systems by offering a pre-assembled, pre-aligned, and sealed solution that simplifies installation and enhances reliability. Slew drives are engineered to handle complex combinations of loads, including axial, radial, and moment loads simultaneously, making them indispensable components in various heavy-duty industrial applications where precise rotational positioning is required.

The Application of Slew Drives in Welding Positioners

In welding positioners, slew drives serve as the fundamental rotational mechanism that enables precise manipulation and positioning of workpieces during welding operations. These systems are critical for achieving optimal weld quality, operator safety, and production efficiency. Welding positioners utilize slew drives to rotate large, often irregularly shaped workpieces into the ideal position for welding, allowing the welder to work on horizontal surfaces whenever possible, which significantly improves weld quality and reduces operator fatigue. The slew drive's ability to provide smooth, continuous rotation with precise control allows for consistent weld speed and bead placement, essential for high-quality fabrication outcomes.

Heavy-duty welding positioners employed in industries such as shipbuilding, pressure vessel manufacturing, and structural steel fabrication rely on robust slew drives capable of handling extremely heavy loads ranging from several hundred kilograms to multiple tons. The precision control offered by slew drives, particularly those with worm gear configurations, ensures accurate angular positioning, which is crucial when working on complex assemblies requiring multiple welds at specific angles. Many modern welding positioners incorporate programmable logic controllers that interface with slew drive motors, enabling automated welding sequences and repeatable positioning for batch production. The sealed construction of quality slew drives protects internal components from welding spatter, dust, and other contaminants prevalent in manufacturing environments, ensuring long-term reliability and reducing maintenance requirements. By providing stable, vibration-free rotation, slew drives help maintain consistent arc length and welding parameters throughout the rotational cycle, directly contributing to improved weld integrity and reduced rework rates.

Slew Drive Characteristics

Slew drives possess several distinct characteristics that make them particularly suitable for demanding applications like welding positioners. Their most notable feature is the ability to generate exceptionally high torque output in a compact form factor, achieved through efficient gear reduction systems that multiply motor torque while reducing output speed. This high torque density enables them to rotate massive workpieces with precise control. The integrated design of slew drives represents another significant characteristic, as they combine multiple components including bearings, gears, seals, and often motors into a single sealed unit that reduces installation complexity and improves overall system reliability.

Precision positioning capability is another critical characteristic, with many slew drives offering low backlash operation and precise angular resolution that enables accurate workpiece orientation. This is particularly important in automated welding applications where repeatable positioning is essential for consistent quality. Their robust construction allows them to withstand harsh operating environments, including exposure to welding spatter, temperature variations, and particulate contamination, while maintaining performance reliability. The modularity and configuration flexibility of slew drives allow engineers to select from various mounting options, gear ratios, drive types, and motor interfaces to match specific application requirements.

Many slew drive designs incorporate built-in safety features such as mechanical self-locking in worm gear configurations, which prevents unwanted movement and holds positions securely even when power is disconnected. This is particularly valuable in welding applications where unexpected rotation could create safety hazards or damage workpieces. The efficiency of modern slew drives has significantly improved through advanced gear designs, premium lubricants, and optimized sealing systems that reduce friction and energy consumption while extending service intervals.

Slew Drive Applications

Beyond welding positioners, slew drives serve numerous applications across various industries that require controlled rotational movement under load. In renewable energy, they are essential components in solar tracking systems, precisely orienting photovoltaic panels to follow the sun's path throughout the day, thereby maximizing energy generation efficiency. Wind turbine manufacturers utilize large slew drives in yaw and pitch control systems to optimize blade angle relative to wind direction and speed. The construction equipment industry extensively employs slew drives in excavators, cranes, and concrete pumps where they provide the rotational capability for upper structures and booms.

Material handling equipment such as rotary conveyors, stacker-reclaimers, and industrial robots rely on slew drives for precise positioning and movement control. In the aerospace and defense sectors, slew drives are critical components in radar systems, satellite antennas, and weapon positioning systems where accuracy and reliability are paramount. Entertainment industries use them in rotating stages, Ferris wheels, and other amusement rides where smooth, controlled rotation enhances guest experiences while ensuring safety. Industrial automation applications include indexing tables, assembly positioners, and packaging machinery that require precise rotational indexing and positioning.

The mining industry utilizes heavy-duty slew drives in drilling rigs, conveyor turntables, and processing equipment where they must operate reliably in extremely harsh conditions with minimal maintenance. Marine applications include deck cranes, winch systems, and propulsion steering mechanisms that benefit from the compact, integrated design of modern slew drives. Agricultural machinery manufacturers incorporate them into irrigation systems, conveyor rotators, and specialized harvesting equipment where reliability and resistance to environmental contaminants are essential.

Factors Influencing Slew Drive Price

The cost of a slew drive is determined by multiple factors that reflect its technical specifications, performance requirements, and manufacturing quality. Load capacity represents the primary cost driver, as units designed to handle higher moment, axial, and radial loads require larger bearings, more robust gearing, and heavier structural components that increase material and manufacturing costs. The torque requirements significantly impact price, with higher torque ratings necessitating larger gear sets, more powerful drive mechanisms, and heavier-duty components throughout the assembly.

Precision requirements greatly influence cost, as drives manufactured to tighter tolerances with lower backlash specifications require more advanced manufacturing processes, specialized equipment, and additional quality control measures. The choice of gear type affects pricing, with worm gear drives typically being more cost-effective for applications requiring self-locking capability, while planetary gear systems command premium pricing for applications demanding higher efficiency and precision. Material selection constitutes another significant factor, with premium materials such as case-hardened alloy steels, specialized bearing steels, and advanced sealing materials increasing cost but enhancing performance and longevity.

Customization requirements substantially impact pricing, as modifications to standard designs including special mounting configurations, unique sealing solutions, custom gear ratios, or special surface treatments require additional engineering and manufacturing resources. Motor integration options affect cost, with drives supplied with integrated motors, brakes, or encoders being more expensive than bare units. Environmental protection ratings influence price, as drives designed for higher IP protection classes or specific environmental resistance require more sophisticated sealing systems and protective treatments.

Brand reputation and certification requirements contribute to cost variations, with manufacturers holding quality certifications such as ISO 9001 typically commanding premium prices that reflect their investment in quality systems and processes. Finally, quantity and procurement terms affect unit pricing, with volume purchases typically benefiting from economies of scale that reduce per-unit costs.

Slew Drive Supplier

LYRADRIVE has established itself as a prominent manufacturer and supplier of high-performance slew drives for industrial applications worldwide. The company's product portfolio encompasses a wide range of standard and customized slew drive solutions engineered to meet the demanding requirements of modern manufacturing and automation systems. LYRADRIVE's technical expertise extends across multiple drive technologies including worm gear, planetary gear, and hybrid systems, allowing them to provide optimal solutions for specific application requirements. Their engineering team collaborates closely with clients to develop customized solutions that address unique challenges in load capacity, environmental conditions, and integration requirements. The company maintains rigorous quality standards throughout its manufacturing processes, utilizing advanced production equipment and comprehensive testing protocols to ensure product reliability and performance. LYRADRIVE's global distribution and support network provides customers with technical assistance, maintenance services, and replacement parts, ensuring optimal performance throughout the equipment lifecycle. By combining technical innovation with practical application expertise, LYRADRIVE delivers slew drive solutions that enhance equipment performance, reliability, and operational efficiency across diverse industrial sectors.