Lubrication in Worm Gear Slew Drives A Comprehensive Guide to Practices and Importance

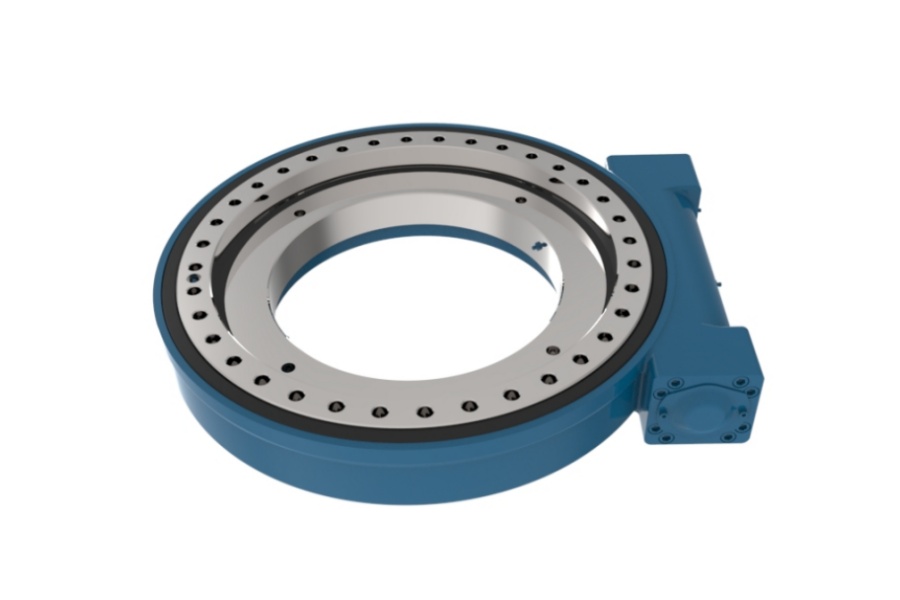

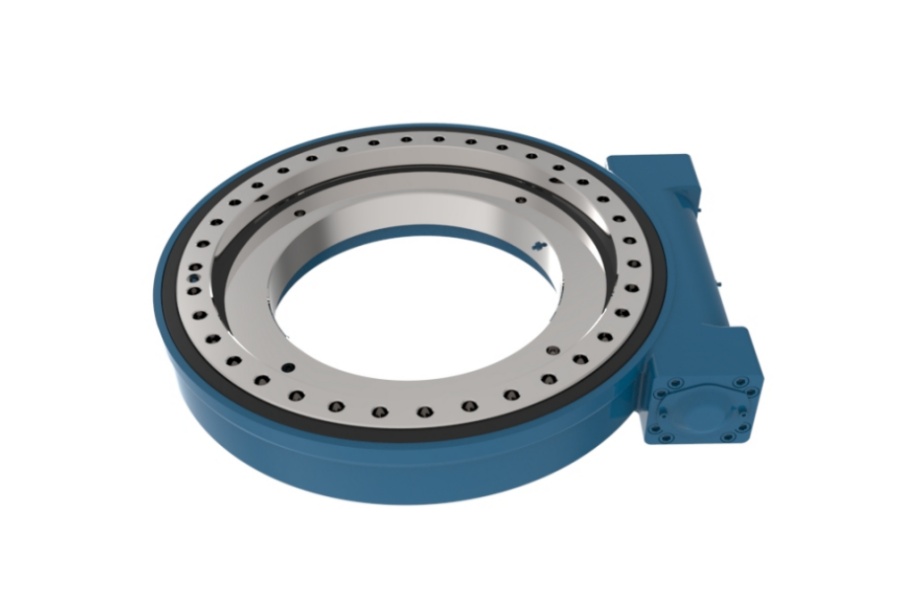

What is a Worm Gear Slew Drive

A Worm Gear Slew Drive is an integrated gearbox that facilitates slow rotation and precise positioning under high load conditions. It combines a worm gear mechanism, consisting of a hardened steel worm screw and a typically bronze alloy worm wheel, with a slewing bearing into a single compact and sealed unit. The primary function of this system is to convert a high-speed, low-torque input from an electric or hydraulic motor into a low-speed, high-torque output rotation. This makes it an indispensable component for applications requiring robust and controlled movement of heavy loads. The unique meshing action between the worm screw and the worm wheel is characterized by a significant amount of sliding contact, which inherently generates friction and heat. This fundamental characteristic makes the role of lubrication not just beneficial but absolutely essential for the unit's basic functionality and durability. The entire assembly is housed within a rigid structure that often includes mounting flanges and seals, designed for easy integration into larger machinery and systems.

Lubrication in Worm Gear Slew Drives

Lubrication is the lifeblood of a worm gear slew drive, directly influencing its efficiency, thermal performance, wear rate, and overall service life. The sliding action inherent in worm gear operation creates constant metal-to-metal contact. Without a proper lubricant, this would quickly lead to excessive wear, searing, and catastrophic failure. The lubricant's primary functions are to separate these metal surfaces with a protective film, reduce friction, dissipate the heat generated by that friction, protect against corrosion, and help in sealing out contaminants.

Selecting the correct lubricant is a critical decision. For worm gear slew drives, high-viscosity, high-viscosity-index oils or semi-fluid greases with extreme pressure (EP) additives are typically specified. These EP additives are crucial as they react chemically with metal surfaces under high pressure to prevent welding and scoring. The lubricant must also possess excellent thermal stability to resist breakdown under operating heat and oxidation over time. Adherence to the manufacturer's specifications for lubricant type and viscosity grade is paramount, as an incorrect choice can be as damaging as having no lubrication at all.

The lubrication process itself must be meticulous. Many slew drives are equipped with grease fittings (zerks) for relief and fill ports. The standard procedure involves purging the old lubricant by pumping new grease into the fill port until clean grease emerges from the relief port. This method ensures the removal of degraded lubricant and accumulated wear particles. The frequency of relubrication is not a fixed interval but depends on the operating conditions. Factors such as temperature extremes, continuous versus intermittent operation, exposure to moisture or abrasive dust, and the intensity of load cycles all significantly impact lubrication lifespan. A drive operating in a dirty, hot, and continuous environment will require far more frequent lubrication intervals than one in a clean, cool, and intermittent duty cycle. Regular oil analysis or inspection of purged grease can provide valuable insights into the internal condition of the drive and help optimize maintenance schedules.

Worm Gear Slew Drive Characteristics

Worm Gear Slew Drives are defined by a set of distinct characteristics that make them suitable for demanding applications. Their most renowned feature is inherent self-locking. Due to the high friction angle within the worm gear set, it is generally impossible to back-drive the system. This means a force applied to the output cannot cause the input worm to rotate, providing an integrated braking safety feature that holds loads securely without the need for an external brake. This is a critical safety and design advantage.

Another key characteristic is their ability to achieve high reduction ratios and tremendous output torque in a single compact stage. The gear ratio is determined by the number of threads on the worm and the number of teeth on the wheel, allowing for significant torque multiplication within a very space-efficient envelope. This integrated design simplifies the overall machinery design by combining multiple components into one pre-assembled, aligned, and sealed unit, reducing engineering complexity and installation time.

Furthermore, these drives are valued for their smooth and quiet operation. The continuous sliding contact of the worm gear mesh, when properly lubricated, produces motion with less vibration and noise compared to some other gear types. Finally, they are known for their robustness and high impact load resistance. The large contact area between the worm and the wheel allows the drive to absorb and distribute shock loads effectively, protecting the drive and the broader system from damage.

Worm Gear Slew Drive Applications

The unique combination of high torque, compact design, self-locking, and controlled motion makes the Worm Gear Slew Drive a critical component across a wide array of heavy-duty industries. In the renewable energy sector, they are the fundamental actuation mechanism in solar tracking systems. They precisely and reliably tilt and rotate massive arrays of solar panels to follow the sun's trajectory throughout the day, maximizing energy capture. Their self-locking capability is essential for holding these large structures in place during high winds.

The construction and heavy equipment industry relies heavily on slew drives. They form the core rotational mechanism for excavators, mobile cranes, and rotary drilling rigs, enabling the upper structure to slew 360 degrees. Their ability to handle immense moment loads and shock conditions while providing smooth, controlled rotation is critical for both performance and safety on the job site. In industrial automation, these drives are found in welding manipulators, heavy-duty turntables, and material handling positioners. They provide the precise and sturdy rotation needed for positioning large workpieces for machining, assembly, or inspection.

Other significant applications include radar and satellite communication antennae, where precise movement and absolute positional accuracy are required under various environmental conditions. The leisure industry also utilizes them in large amusement rides like Ferris wheels, where their reliability and safety are non-negotiable. Finally, they are increasingly used in advanced robotics, particularly for the base joint of large robotic arms, where their high torque density and stability are major advantages.

Factors Influencing Worm Gear Slew Drive Price

The cost of a Worm Gear Slew Drive is influenced by a multitude of factors that reflect its design complexity, manufacturing quality, and performance capabilities. The most fundamental cost driver is the physical size and torque capacity of the unit. A larger drive engineered to handle higher output torque and moment loads will require more raw material, larger bearings, and more robust internal gearing, directly increasing its manufacturing cost.

The materials selected for key components, especially the worm and worm wheel, significantly impact the price. A standard carbon steel worm paired with a phosphor bronze wheel is a common configuration. However, applications demanding higher durability, better efficiency, or operation in corrosive environments might require a case-hardened and precision-ground alloy steel worm mated with a specialized copper-alloy or composite wheel. These premium materials and the additional processing steps involved add considerable expense.

The required precision grade and performance specifications are another major factor. A drive specified for very low backlash, high positional accuracy, or exceptional tolerances for smoothness requires more advanced manufacturing techniques, stricter quality control measures, and often selective assembly, all of which contribute to a higher unit cost. Any form of customization will also affect the price. This includes special sealing solutions for extreme temperatures or submersion, custom mounting flanges or output shaft configurations, integrated motors or brakes, and unique surface treatments like special paints or coatings.

Finally, the manufacturer's brand reputation, quality certifications (such as ISO 9001), and the extent of post-sales technical support and warranty provided are reflected in the price. Established manufacturers with a proven track record of reliability and comprehensive global support often command a premium, which is justified by the reduced risk of failure and operational downtime for the customer.

Worm Gear Slew Drive Supplier

For engineers and procurement specialists seeking a reliable source for high-performance Worm Gear Slew Drives, LYRADRIVE presents itself as a formidable partner in the global market. The company has built a strong reputation for engineering and manufacturing robust, precision slew drives that meet the demanding requirements of various heavy-industry applications. LYRADRIVE's product portfolio is characterized by a commitment to rigorous quality control, utilizing superior materials and advanced manufacturing processes to ensure durability, efficiency, and long service life. They possess deep expertise in the critical area of lubrication management, offering drives that are optimally pre-lubricated and designed for effective maintenance throughout their operational lifespan. Beyond standard offerings, LYRADRIVE provides significant value through its engineering support and customization capabilities, working closely with clients to adapt drives for specific operational needs, whether it involves unique mounting configurations, special seals, or integration with specific motor types. By choosing LYRADRIVE, customers secure not just a component, but a partnership with a supplier dedicated to delivering the power, reliability, and precision necessary to drive their most challenging projects forward.