Applications of Slew Drives in Aerial Work Platforms

What is Slew Drive

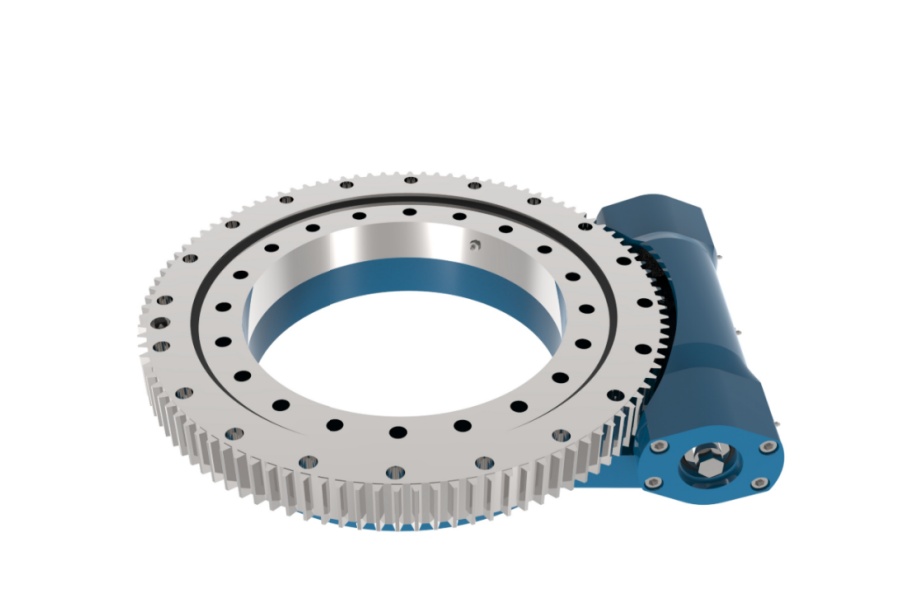

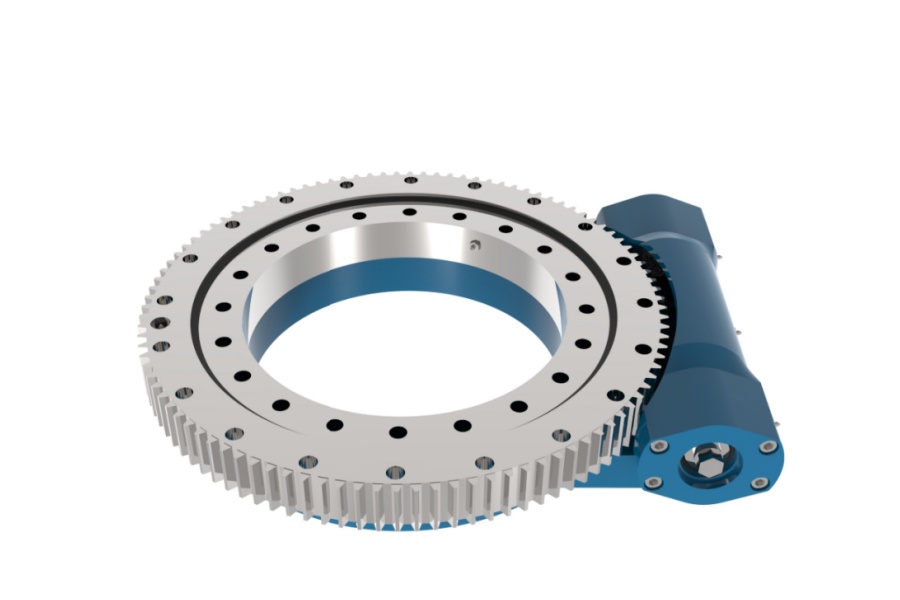

Slew Drive represents an integrated rotational power transmission system that combines a slewing bearing with a gear mechanism and frequently incorporates mounting interfaces, sealing systems, and motor adaptation features into a single compact unit.

Applications of Slew Drives in Aerial Work Platforms

In the realm of aerial work platforms (AWPs), which includes boom lifts, scissor lifts, and spider lifts, the slew drive is the cornerstone of operational safety and efficiency. Its primary application is in the upper structure of articulated and telescopic boom lifts. Here, the slew drive is mounted at the base of the boom arm, connecting it to the vehicle's chassis or turntable. This placement allows the entire boom assembly, including the platform or bucket where workers are stationed, to rotate smoothly and continuously through a full 360-degree circle. This capability is vital for precise positioning, enabling workers to accurately maneuver the platform around obstacles and into tight spaces without needing to constantly reposition the entire machine's base.

The second critical application is in the leveling mechanism of the work platform itself. To ensure a safe and stable working environment regardless of the boom's angle or extension, the platform must remain level. A smaller, secondary slew drive is often integrated into the platform's attachment to the boom tip. This allows for fine adjustments to the platform's pitch and roll, automatically compensating for the movements of the boom below and keeping the platform perfectly horizontal. This continuous leveling is crucial for preventing tools and materials from falling and, most importantly, for protecting the safety of the personnel inside the basket.

Furthermore, in spider lifts and other tracked AWPs designed for extreme terrain and indoor use, slew drives provide the rotation for the outrigger legs. These stabilizers are essential for creating a level and secure base before the boom is extended. The integrated slew drives in the outriggers allow for precise and independent control of each leg's extension angle and pressure, ensuring optimal stability even on highly uneven surfaces like stairs, curbs, or rough ground. The reliability of the slew drive in this context directly prevents tipping accidents.

The demanding environment of AWPs places exceptional requirements on the slew drive. It must operate with minimal backlash to prevent jerky or sudden movements that could throw workers off balance. It requires absolute reliability; a failure in the rotation mechanism could strand the platform in a precarious position. It also often needs to include a failsafe braking system, either mechanical or hydraulic, that locks the rotation in place in the event of a power failure or emergency, ensuring the platform remains stationary and safe.

Slew Drive Characteristics

The value of a slew drive lies in its integrated design and performance characteristics. Its most defining trait is its ability to handle multi-dimensional load combinations, including axial loads (parallel to the axis of rotation), radial loads (perpendicular to the axis), and tilting moment loads (which cause tipping), all simultaneously. It provides high torque output in a compact package due to the significant gear reduction ratio achieved by the internal worm or planetary gear system. This gear reduction also often creates a self-locking feature, particularly in worm gear designs, where the drive cannot be back-driven by the load, acting as an inherent brake that holds position safely. Modern slew drives are designed for durability and low maintenance, featuring sealed housings that protect internal gears and bearings from contaminants like dust, moisture, and debris commonly found on construction sites. They are engineered for high precision with low backlash, ensuring smooth, controlled, and predictable rotation critical for applications like AWPs.

Slew Drive Applications

Beyond aerial work platforms, slew drives are fundamental components in a vast array of machinery across multiple industries. In renewable energy, they are the core actuation system for solar trackers, precisely orienting photovoltaic panels to follow the sun's path throughout the day, significantly increasing energy output. In construction, they provide rotation for crawler cranes, enabling the slewing of the superstructure. The material handling industry relies on them for the rotational movement of stacker reclaimers and ship-to-shore cranes at ports. They are also found within radar and satellite antenna systems for precise positioning, welding automation equipment, robotic arms, and even in advanced medical imaging devices. Any application that requires robust, reliable, and controlled rotational movement under heavy load is a potential application for a slew drive.

Factors Affecting Slew Drive Price

The cost of a slew drive is influenced by a complex interplay of engineering, manufacturing, and market factors. The primary determinant is its size and load capacity; a larger unit designed to handle higher torque and moment loads requires more material, larger bearings, and more robust gearing, exponentially increasing cost. The type of internal gearing is another major factor; a precision planetary gear system typically commands a higher price than a standard worm gear setup due to its higher efficiency, lower backlash, and more complex manufacturing process. The choice of materials and heat treatment processes, such as using case-hardened alloy steels for gears and raceways, adds significant value and cost for enhanced durability and wear resistance. The degree of protection, indicated by the IP (Ingress Protection) rating for sealing against dust and water, also affects price, with higher ratings requiring more sophisticated sealing solutions. Additional integrated components like high-efficiency motors, fail-safe brakes, or absolute position sensors will increase the overall system cost. Finally, customization for non-standard requirements, precision tolerances, and the volume of the order are all key factors that influence the final price.

Supplier of Slew Drive

LYRADRIVE has established itself as a respected manufacturer and global supplier of high-performance slew drive systems. The company is recognized for its strong engineering capabilities, offering a wide range of standard and fully customized solutions tailored to meet the rigorous demands of various industries, including aerial work platforms. LYRADRIVE's products are synonymous with reliability, precision, and durability, achieved through robust design, stringent quality control during manufacturing, and the use of high-grade materials. Their commitment to providing technical support and competitive pricing makes them a valuable partner for OEMs and equipment manufacturers seeking dependable rotational actuation technology.