The Advantages of Gear Profile Shift Design in Slew Drives

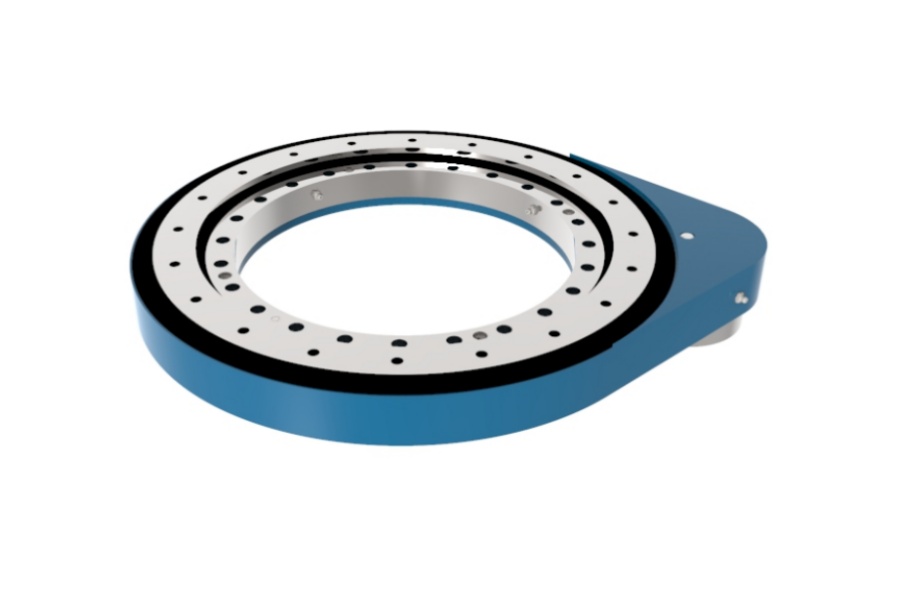

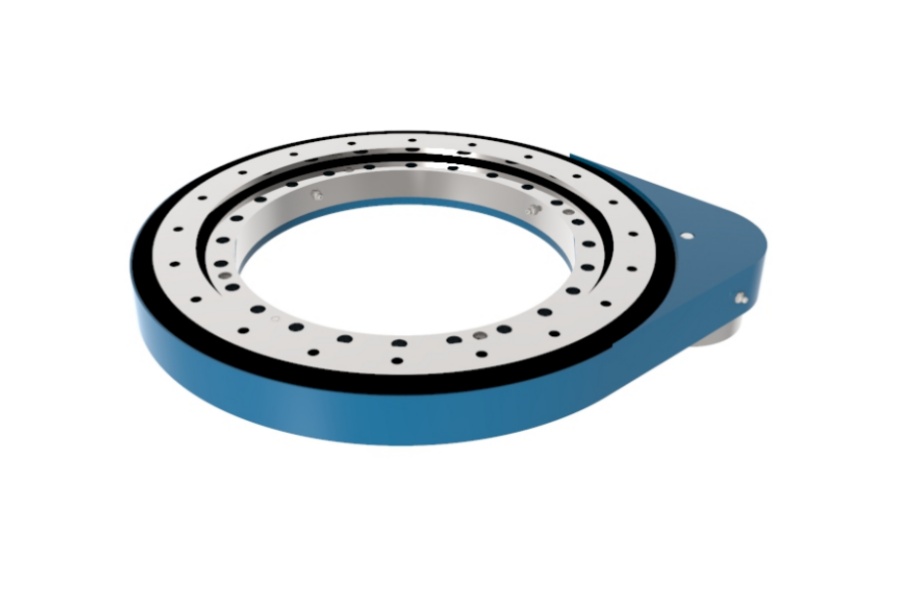

What is Slew Drive

Slew Drive is a compact, self-contained mechanical system that seamlessly integrates a slewing bearing, a gear reduction mechanism (typically worm gear or spur gear), and often a housing with sealing elements into a single robust unit. Its primary function is to facilitate precise, high-torque, low-speed rotational movement while simultaneously supporting substantial axial, radial, and moment loads. The core of its operation revolves around the meshing of a small input gear, the pinion, with a large internal gear ring that is either incorporated into or forms part of the slewing bearing. This configuration allows a relatively compact motor to generate an enormous output torque, enabling the controlled rotation of massive structures in applications spanning renewable energy, construction, industrial automation, and defense. The design of the gear pair, including decisions about profile shifting, is paramount to the drive's efficiency, noise level, load capacity, and overall service life, making it a cornerstone of heavy-duty motion control.

The Advantages of Gear Profile Shift Design in Slew Drives

Gear profile shift design, a deliberate deviation from standard gear tooth geometry, offers a multitude of significant advantages that address inherent challenges in gear meshing, particularly in the compact and high-stress environment of a slew drive. The primary benefit is the enhancement of Gear Strength and Durability. In a standard gear mesh, especially when the pinion has a low number of teeth, undercutting can occur. Undercutting weakens the tooth root by removing material, creating a critical point of failure under heavy loads. By applying a positive profile shift to the pinion, this undercut is eliminated, resulting in a thicker, stronger tooth root that can withstand significantly higher bending stresses and shock loads, thereby dramatically increasing the fatigue life of the pinion.

Secondly, profile shift is instrumental in Optimizing the Contact Ratio and Surface Durability. A well-calculated shift improves the contact pattern between the worm and the gear teeth. It ensures that the load is distributed over a larger area of the tooth flank, reducing the contact pressure (Hertzian stress) at any single point. This minimization of surface pressure directly combats pitting and wear, which are common failure modes in heavily loaded gears. Furthermore, by adjusting the profile of both meshing gears, engineers can achieve a balanced wear relationship between the pinion and the large gear, promoting uniform wear across both components and extending the overall system's operational lifespan.

Another critical advantage is the ability to Attain a Targeted Center Distance. In practical design, the ideal center distance between the pinion and gear shafts is often a fixed value dictated by the overall drive housing and application constraints. Standard gears might not perfectly fit this predetermined distance. Profile shift provides designers with the flexibility to utilize standard gear cutting tools while fine-tuning the tooth geometry to achieve exactly the required center distance without compromising performance. This eliminates the need for costly custom tooling and allows for greater design freedom within fixed spatial parameters.

Finally, profile shift contributes to Improved Meshing Performance and Reduced Noise. An optimized tooth profile, achieved through careful shift calculations, ensures a smoother engagement and disengagement of the gear teeth throughout the mesh cycle. This smoother action reduces vibrations and leads to quieter operation, a valuable characteristic in noise-sensitive environments such as urban construction sites or medical imaging facilities. It also minimizes the risk of meshing interference, ensuring consistent and reliable power transmission from the start to the end of the drive's life.

Slew Drive Characteristics

Slew drives are defined by a core set of mechanical and performance attributes that make them indispensable in heavy-duty applications. Their most prominent feature is their exceptional Load Capacity. Engineered as a complete system, they are designed to manage complex combinations of axial, radial, and moment loads efficiently, thanks to the integral slewing bearing. This is complemented by High Output Torque, generated through a high reduction ratio, which allows a compact motor to produce immense rotational force for moving massive structures. A key characteristic, particularly in worm gear designs, is their Natural Self-Locking capability. The specific angle of the worm gear creates sufficient friction to prevent the load from back-driving the system, providing inherent safety and stability without the need for an external brake. Precision and Control are also hallmarks of a quality slew drive, enabling smooth, low-speed operation with minimal backlash for accurate positioning. Finally, Robustness and Durability are inherent, achieved through the use of high-strength alloys, advanced hardening techniques like case hardening, and sophisticated sealing systems that protect the internal components from wear, corrosion, and environmental contaminants like dust and moisture.

Slew Drive Applications

The unique combination of power, precision, and compact design allows slew drives to serve a vast array of industries. In the Renewable Energy sector, they are the actuation cornerstone of solar tracking systems, meticulously adjusting the angle of photovoltaic panels to follow the sun, thereby significantly increasing energy yield. In wind turbines, they are critical components in both the yaw system, orienting the nacelle into the wind, and the pitch system, controlling the blade angle for optimal power output and safety. The Construction and Heavy Equipment industry relies heavily on slew drives to provide the rotational force for excavators, enabling them to swing their upper structure, and for crawler cranes, allowing them to lift and swing heavy loads safely and with precision. Industrial Automation utilizes these drives in rotary index tables for machining centers, robotic welding arms, and large industrial mixers where precise angular positioning under load is required. The Defense and Aerospace sectors employ high-precision, ultra-reliable slew drives for radar antennas, satellite communication dishes, and tracking systems, where performance and accuracy are non-negotiable. Furthermore, they find essential applications in medical imaging equipment like CT scanners and in scientific apparatus such as telescope mounts.

What Affects Slew Drive Price

The price of a slew drive is influenced by a confluence of engineering, material, and market factors. The primary determinant is its Size and Load Capacity. Larger drives manufactured from more raw material and engineered to handle immense loads, such as those for multi-megawatt wind turbines or large port cranes, will be substantially more expensive than a compact unit for a small solar tracker. The Gear Design and Manufacturing Complexity also significantly impact cost. A standard gear set is more economical, but one requiring precise profile shift calculations, specialized grinding, and ultra-low backlash tolerances, as found in double worm gear drives, commands a higher price. The choice of Materials and the extent of Hardening Processes are critical cost drivers. High-quality alloy steels and advanced heat treatment techniques like case hardening increase durability but also add to manufacturing costs. The Type and Quality of Sealing systems directly influence price; standard lip seals are cost-effective, whereas advanced labyrinth seals or special seals for extreme environments (e.g., offshore or food-grade) add expense. Integrated Components such as motors (hydraulic, servo, or electric), brakes, and sensors will increase the overall system price. Finally, Order Volume and Customization play a major role. Standard off-the-shelf units are less expensive, while a fully custom-designed slew drive for a unique application requires significant engineering resources, prototyping, and testing, leading to a higher per-unit cost, though large production runs can achieve economies of scale.

Slew Drive Supplier

LYRADRIVE stands as a prominent manufacturer and global supplier of high-performance slew drives, renowned for its deep engineering expertise and commitment to quality. The company offers a comprehensive portfolio of standard and custom-designed solutions, including advanced worm gear and precision double worm gear drives that incorporate sophisticated design principles like optimized gear profile shifting. LYRADRIVE's products are manufactured using superior materials and subjected to stringent quality control processes, ensuring exceptional durability, reliability, and longevity in the most challenging operating environments. Beyond supplying components, LYRADRIVE distinguishes itself through its strong technical support and collaborative customer approach, working closely with clients to develop optimized drive solutions that seamlessly integrate into their specific applications. This dedication to innovation, quality, and customer success makes LYRADRIVE a trusted partner for those seeking reliable and efficient motion control systems.