Why Pinion and Gear Have Different Hardness in Slew Drives

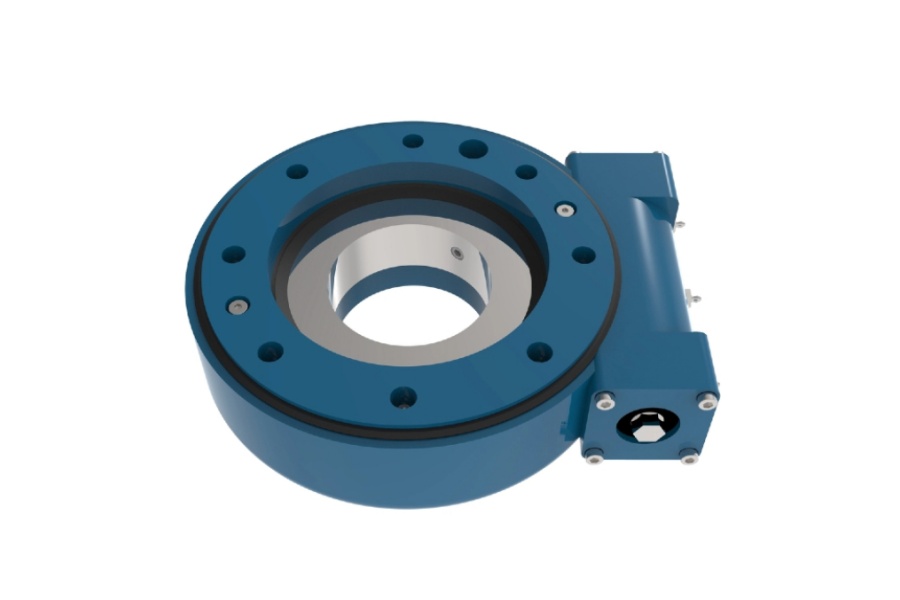

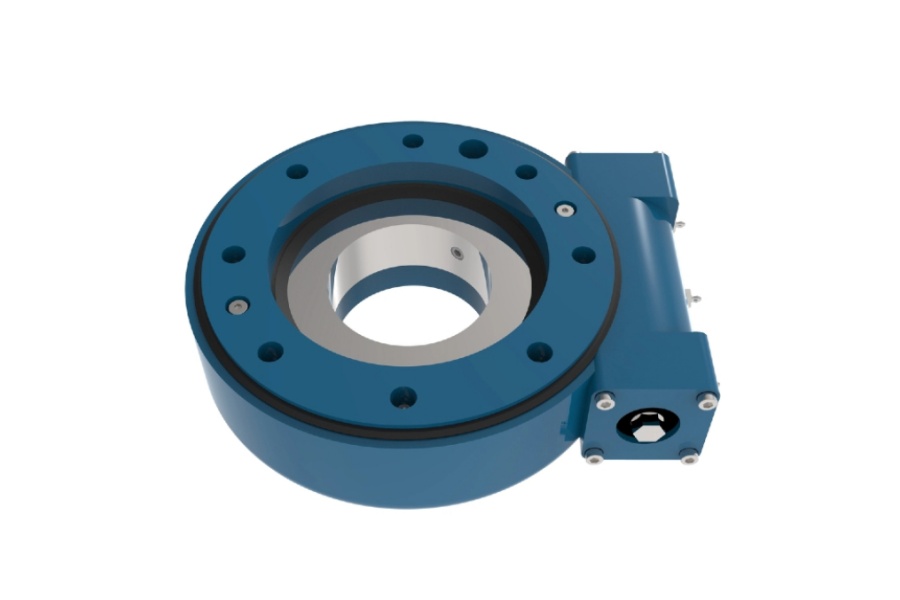

What is Slew Drive

Slew Drive is a compact, highly integrated mechanical assembly that combines a slewing bearing, a worm or spur gearbox, and often a mounting housing and sealing system into a single, self-contained unit. Its primary function is to provide precise, high-torque, low-speed rotational movement to heavy equipment while simultaneously supporting substantial axial, radial, and moment loads. The core of its operation involves a small input gear, known as the pinion (which can be a worm or a spur gear), meshing with a large gear ring that is integral to the slewing bearing's structure. This configuration allows a relatively small motor to generate a massive output torque, facilitating the controlled rotation of massive structures. Slew drives are prized for their ability to deliver powerful and precise motion in a space-efficient package, making them indispensable in applications ranging from solar energy and construction to aerospace and industrial automation. Their robust design is engineered for durability and reliable performance in the most demanding environments.

Why Pinion and Gear Have Different Hardness in Slew Drives

The strategic difference in tooth hardness between the pinion and the main gear is a fundamental principle in slew drive design, crucial for maximizing the system's service life and operational reliability. This intentional hardness gradient is implemented primarily to manage wear and prevent catastrophic failure modes. The pinion, being the smaller gear, experiences a significantly higher number of engagement cycles than the main gear. For every full rotation of the main gear, the pinion must rotate multiple times. This disparity in cycle count means the pinion teeth are subjected to wear and fatigue at a much faster rate. To counteract this, the pinion is manufactured from a harder material and undergoes a more intensive hardening process, such as case hardening or induction hardening. This gives its surface extreme resistance to abrasion and pitting, allowing it to withstand its high cyclical duty.

Conversely, the large main gear, often a integral part of the costly slewing bearing, is treated to a lower surface hardness. This is a deliberate choice for several reasons. First, if both gears were of equal and extreme hardness, the interaction would be brittle-on-brittle. Any misalignment, shock load, or contamination could cause not just wear, but catastrophic chipping or fracturing of teeth on both components. A slightly softer main gear is more ductile and forgiving. It can absorb minor impacts and deform slightly without cracking, making the system more robust against unexpected operational stresses. Second, in the event of inevitable wear over an extremely long lifespan, it is far more economical and practical to replace the smaller, easier-to-access pinion than the large, expensive main gear and bearing assembly. By designing the system so that the harder pinion wears down the softer main gear at an imperceptibly slow rate, engineers ensure that any wear is concentrated on the more replaceable component. This hardness differential effectively acts as a sacrificial wear management system, protecting the most valuable and difficult-to-replace part of the drive. It optimizes performance, minimizes downtime, and reduces the total cost of ownership over the machinery's lifespan.

Slew Drive Characteristics

Slew drives are defined by a set of core characteristics that make them unique and invaluable in heavy-duty applications. Their most prominent feature is their exceptional Load Capacity. Engineered to handle complex load combinations, they simultaneously manage axial, radial, and moment loads efficiently, thanks to the integrated slewing bearing design. This is complemented by High Output Torque, which allows a compact motor to generate immense rotational force through a high reduction ratio, enabling the movement of massive structures with precision. A key characteristic, especially in worm gear designs, is their Natural Self-Locking ability. The specific angle of the worm gear creates sufficient friction to prevent the load from back-driving the system, providing inherent safety and stability without the need for an external brake. Precision and Control are also hallmarks of a quality slew drive. They are designed for smooth, low-speed operation with minimal backlash, allowing for accurate positioning and repeatable movement critical in applications like solar tracking or robotic arms. Finally, Robustness and Durability are built into their DNA. Constructed from high-strength alloys and featuring advanced sealing systems, they are built to perform reliably in harsh environments, resisting wear, corrosion, and contamination from dust and moisture.

Slew Drive Applications

The unique combination of power, precision, and compactness allows slew drives to serve a vast array of industries. In the Renewable Energy sector, they are the cornerstone of solar tracking systems, meticulously adjusting the angle of photovoltaic panels to follow the sun, thereby significantly increasing energy yield. In wind turbines, they function in both the yaw system, orienting the nacelle into the wind, and the pitch system, controlling the blade angle for optimal power output and safety. The Construction and Heavy Equipment industry relies heavily on slew drives to provide the rotational force for excavators, enabling them to swing their upper structure, and for crawler cranes, allowing them to lift and swing heavy loads safely and with precision. Industrial Automation utilizes these drives in rotary index tables for machining centers, robotic welding arms, and large industrial mixers where precise angular positioning under load is required. The Defense and Aerospace sectors employ high-precision, ultra-reliable slew drives for radar antennas, satellite communication dishes, and weapon systems, where performance and accuracy cannot be compromised. Furthermore, they find applications in Medical imaging equipment like CT scanners and in scientific apparatus such as telescope mounts.

What Affects Slew Drive Price

The price of a slew drive is influenced by a multitude of engineering and market factors. The primary determinant is its Size and Load Capacity. Larger drives manufactured from more raw material and designed to handle immense loads, such as those for multi-megawatt wind turbines or large port cranes, will be substantially more expensive than a compact unit for a small solar tracker. The Gear Type and Design Complexity also significantly impact cost. A standard single worm gear drive is generally more economical. A double worm gear drive, with its additional components and precision machining required for ultra-low backlash, commands a higher price. The choice of materials and the extent of Hardening Processes are critical cost drivers. High-quality alloy steels and advanced hardening techniques like case hardening increase durability but also manufacturing costs. The Type and Quality of Sealing systems directly influence price; standard lip seals are cost-effective, whereas advanced labyrinth seals or special seals for extreme environments (e.g., offshore or food-grade) add expense. Integrated Components such as motors (hydraulic, servo, or electric), brakes, and sensors will increase the overall system price. Finally, Order Volume and Customization play a major role. Standard off-the-shelf units are less expensive, while a fully custom-designed slew drive for a unique application requires significant engineering resources, prototyping, and testing, leading to a higher per-unit cost, though large production runs can achieve economies of scale.

Slew Drive Supplier

LYRADRIVE stands as a prominent manufacturer and global supplier of high-performance slew drives, renowned for its engineering expertise and commitment to quality. The company offers a comprehensive portfolio of standard and custom-designed solutions, including robust worm gear and precision double worm gear drives, tailored to meet the rigorous demands of diverse industries such as renewable energy, construction, and industrial automation. LYRADRIVE's products are manufactured using superior materials and subjected to stringent quality control processes, ensuring exceptional durability, reliability, and longevity in the most challenging operating environments. Beyond supplying components, LYRADRIVE distinguishes itself through its strong technical support and collaborative customer approach, working closely with clients to develop optimized drive solutions that seamlessly integrate into their specific applications. This dedication to innovation, quality, and customer success makes LYRADRIVE a trusted partner for those seeking reliable and efficient motion control systems.