Slewing Bearing: The Foundation of Rotational Motion

Slewing bearings, also known as rotary bearings or turntable bearings, represent one of the most critical components in modern machinery requiring rotational movement under heavy loads. These specialized bearing systems form the fundamental rotational interface between structural components in countless industrial applications, from massive wind turbines harnessing renewable energy to the towering cranes that define our urban skylines. Unlike conventional bearings designed primarily for rotary motion, slewing bearings are engineered to withstand complex combination loads—simultaneously handling axial, radial, and moment forces while facilitating precise rotation about a single axis. Their unique design integrates gear teeth directly onto either the inner or outer raceway, creating a multifunctional component that serves as both a structural connection point and a rotational mechanism. As industrial machinery continues to evolve toward greater load capacities, higher precision requirements, and improved operational efficiency, the importance of properly selected and maintained slewing bearings cannot be overstated. This comprehensive examination explores the technical specifications, application considerations, and economic factors surrounding these essential components that quietly enable much of our modern industrial infrastructure.

Table of Contents

Understanding the Basics of Slewing Bearings

What is a Slewing Bearing?

A slewing bearing is a large-scale rotational rolling-element bearing that typically features integrated gear teeth and mounting holes for structural connection. Unlike conventional bearings that are primarily designed to support radial or axial loads separately, slewing bearings are specifically engineered to handle combination loads—axial forces, radial forces, and tilting moments—simultaneously. These components consist of an inner ring and an outer ring, with rolling elements (balls or rollers) positioned between them, and are manufactured in diameters ranging from as small as 100mm to over 15 meters for specialized applications. The integrated gear teeth, which can be located on either the inner or outer ring, enable the transmission of rotational force from a pinion gear, facilitating controlled movement of the structure. Mounting holes drilled directly into both rings allow for direct bolting to structural components, eliminating the need for additional housings and creating a compact, integrated connection system. This design approach significantly simplifies machinery design while providing exceptional load-bearing capacity in a relatively compact form factor.

Key Characteristics of Slewing Bearings

Slewing bearings possess several distinctive characteristics that differentiate them from conventional bearing solutions. Their most notable feature is the ability to handle complex combination loads—a single slewing bearing can simultaneously support axial loads exceeding 10,000 kN, radial loads surpassing 5,000 kN, and tilting moments greater than 50,000 kNm, depending on size and design. These components exhibit exceptional structural rigidity, with deflection rates typically measuring less than 0.1 degrees under maximum load conditions, ensuring precise operational control. The integrated gear teeth are precision-machined to quality standards between DIN 5-8, with hardness typically ranging from 55-60 HRC to ensure long-term wear resistance and efficient power transmission. Slewing bearings are available in various sealing system configurations, commonly utilizing multi-layer labyrinth seals or specialized rubber compounds capable of excluding contaminants while retaining lubrication in demanding environments. Their design life expectancy typically ranges from 25,000 to 100,000 operational hours, depending on application conditions and maintenance practices, with many bearings outlasting the equipment they're installed in when properly maintained.

Benefits of Using Slewing Bearings

The implementation of slewing bearings in mechanical systems delivers numerous significant advantages that contribute to improved equipment performance, reduced complexity, and enhanced operational reliability. One of the primary benefits is their ability to simplify mechanical design by integrating multiple functions into a single component—replacing what would traditionally require separate bearing arrangements, gear mechanisms, and structural support elements. This integration results in substantial space savings, often reducing the required envelope by 30-40% compared to conventional solutions, while simultaneously decreasing overall system weight through the elimination of redundant structural supports. The compact nature of slewing bearings enables more efficient machinery design, particularly valuable in applications where space constraints directly impact operational capabilities, such as in mobile equipment or offshore installations.

From a performance perspective, slewing bearings offer exceptional load distribution characteristics, spreading forces evenly across their large diameter to minimize stress concentrations on supporting structures. This capability allows for the design of lighter supporting frameworks while maintaining structural integrity, potentially reducing material costs by 15-25% in many applications. The precision manufacturing of slewing bearings ensures smooth, consistent rotation with minimal friction, contributing to reduced power requirements for rotation—typically 20-30% lower than equivalent multi-component systems. Their sealed design provides inherent protection against environmental contaminants, significantly extending service intervals while maintaining lubrication integrity, with many modern designs featuring lifetime lubrication that eliminates the need for routine maintenance. The standardized mounting patterns and interface geometries streamline equipment design and manufacturing processes, reducing engineering time and simplifying procurement through the use of established industry standards.

Types of Slewing Bearings

Slewing bearings are available in several distinct configurations, each optimized for specific load conditions and application requirements. The four primary types include:

Single Row Ball Slewing Bearings: Featuring a single raceway with ball rolling elements, these bearings provide an optimal balance between load capacity and compact design. They excel in applications requiring smooth rotation with moderate moment loads, typically handling axial load to moment load ratios of approximately 1:0.8. Common applications include light to medium-duty rotary tables, material handling equipment, and smaller construction machinery. Their relatively simple design makes them cost-effective while providing low-friction operation suitable for manual or low-power actuation systems.

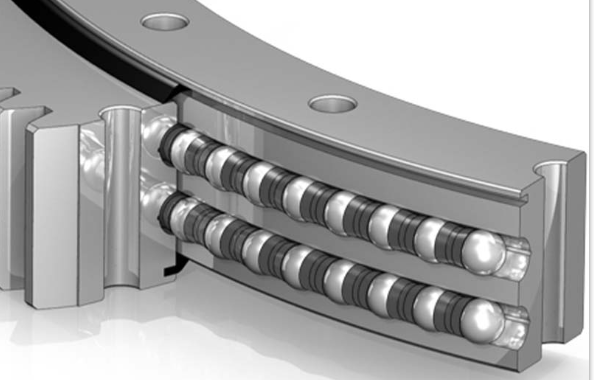

Double Row Ball Slewing Bearings: Utilizing two separate raceways with ball elements, this configuration significantly increases load capacity while maintaining compact dimensions. The dual raceway design provides approximately 40-50% greater moment load capacity compared to single row designs of similar diameter, making them ideal for applications with significant off-center loading. These bearings typically exhibit superior stiffness characteristics, with deflection rates 25-30% lower than equivalent single row designs, ensuring precise positioning under load. They're commonly employed in medium-duty cranes, excavators, and industrial robots where space constraints preclude larger diameter solutions.

Crossed Roller Slewing Bearings: Featuring cylindrical rollers arranged in a crossed pattern between raceways, these bearings provide exceptional rigidity and precision. The crossed roller design enables simultaneous support of all load types (axial, radial, and moment) with minimal elastic deformation, typically demonstrating 50-60% higher stiffness than equivalent ball bearing designs. This configuration offers superior rotational accuracy, with runout tolerances as low as 0.001 inches, making them ideal for precision applications such as machine tool rotary tables, measuring instruments, and telescope mounts. Their compact height profile makes them particularly valuable in applications with axial space constraints.

Three Row Roller Slewing Bearings: Representing the heaviest-duty configuration, these bearings utilize separate rows of rollers dedicated to handling specific load types—typically one row for axial loads and two rows for radial loads. This specialized arrangement provides exceptional load capacity, with large-diameter designs capable of supporting moment loads exceeding 100,000 kNm. The segregated load paths optimize material usage, making them particularly efficient for extreme load applications while maintaining relatively compact dimensions compared to alternative solutions. These bearings are primarily used in the most demanding applications, including heavy-duty mining equipment, large-scale construction cranes, and tunnel boring machines where reliability under extreme loads is paramount.

Installation and Maintenance

Installation Procedures

Proper installation is critical to achieving designed service life and performance from slewing bearings. The process begins with thorough preparation of mounting surfaces, which must be machined to precise flatness tolerances—typically within 0.1-0.3 mm per meter of diameter depending on bearing size and application requirements. Surface finish should achieve a roughness value (Ra) of 3.2-6.3 μm to ensure proper seating without compromising structural integrity. mounting surfaces must be clean and free from burrs, with particular attention paid to the alignment of mounting holes between the bearing and supporting structure. The bearing should be lifted using specifically designated threaded lifting holes (typically provided in the bearing rings) to prevent distortion or damage during handling.

Mounting bolts must be of the specified grade (typically Class 10.9 or higher for most applications) and tightened in a star pattern sequence to the manufacturer's recommended torque values, which are calculated based on bolt size, material strength, and application loads. Proper torque values typically range from 200-800 Nm for standard applications, with large-diameter bearings requiring special tensioning procedures to achieve consistent preload across all bolts. Alignment verification should be performed after initial tightening, checking for uniform contact patterns and ensuring free rotation without binding. Final lubrication of gear teeth and raceways should be performed according to manufacturer specifications, using recommended grease types and quantities based on operational temperature ranges and environmental conditions.

Maintenance Practices

Effective maintenance significantly extends slewing bearing service life and prevents premature failure. Regular inspection intervals should be established based on operational severity, with typical schedules ranging from 250-1,000 operating hours. Visual inspections should examine seal condition, looking for signs of damage, extrusion, or hardening that could compromise contamination exclusion. Lubrication analysis should include both raceway and gear tooth lubrication condition assessment, with re-lubrication performed using specified grease types and quantities—typically 0.3-0.5 kg of grease per meter of bearing diameter for raceway lubrication.

Operational monitoring should include regular checks for unusual noise, increased rotational torque, or visible deformation, any of which may indicate developing issues. Gear tooth inspection should be performed quarterly to assess wear patterns, with particular attention to proper backlash maintenance between the bearing gear and pinion (typically 0.2-0.5 mm depending on module size). For bearings in severe service environments, lubricant analysis can provide early warning of impending failure by detecting elevated levels of wear metals or contamination particles. Re-lubrication procedures must include complete purging of old lubricant to prevent additive breakdown contamination, with special attention to ensuring fresh grease completely circulates through all raceway passages.

Slewing Bearing Cost Analysis

The economic evaluation of slewing bearings requires consideration of both initial investment and long-term operational costs, which together determine the true total cost of ownership. Initial purchase prices vary significantly based on bearing type, size, and specifications—small single row ball bearings (500mm diameter) may cost $500-1,500, while large three row roller bearings (3,000mm diameter) can exceed $50,000-100,000 for specialized applications. Price determinants include material quality (typically 42CrMo4 or 50Mn steel), heat treatment processes (case hardening to 55-60 HRC), gear quality specification (DIN 5-8), and sealing system complexity. Customizations such as special coating requirements, unusual mounting patterns, or non-standard gear modifications typically add 20-40% to base prices.

Operational costs encompass several factors that significantly impact total ownership expense. Maintenance costs for properly specified slewing bearings typically represent 1-2% of initial cost annually when following recommended maintenance schedules, compared to 5-8% for improperly maintained bearings. Energy consumption varies based on sealing system design and lubrication efficiency, with modern low-friction seal designs reducing rotational torque by 15-25% compared to conventional designs, translating to meaningful power savings in continuously operating equipment. Downtime costs represent the most significant potential expense, with bearing failure in critical equipment potentially causing production losses of $10,000-50,000 per day in industrial settings, making reliability considerations paramount in bearing selection.

Lifecycle cost analysis demonstrates that while premium-quality slewing bearings may command 20-30% higher initial prices compared to economy alternatives, they typically deliver 100-300% longer service life, resulting in significantly lower cost per operating hour. This economic advantage is particularly pronounced in applications with high downtime costs or difficult replacement access, where bearing longevity directly impacts overall operational economics. The most cost-effective approach typically involves selecting bearings with appropriate specifications for the application rather than either over-specifying (with associated unnecessary initial cost) or under-specifying (with resulting premature failure and high replacement costs).

Applications of Slewing Bearings

Slewing bearings serve as critical components across diverse industrial sectors, enabling rotational motion in equipment ranging from precision instruments to massive heavy machinery. In the renewable energy sector, they form the core rotational mechanism in wind turbine yaw and pitch systems, with modern multi-megawatt turbines utilizing bearings of 1.5-4.0 meters diameter capable of supporting moment loads exceeding 15,000 kNm while maintaining precise positioning accuracy despite varying wind loads. The construction industry employs slewing bearings extensively in mobile cranes, tower cranes, and excavators, where they provide the reliable rotational base for boom movement—typically using three row roller designs for maximum load capacity in space-constrained applications.

Industrial manufacturing utilizes precision slewing bearings in machine tool rotary tables, welding positioners, and indexing equipment, where crossed roller designs provide the exceptional rigidity and accuracy required for machining tolerances within 0.001 inches. The material handling sector incorporates slewing bearings in port container cranes, stacker-reclaimers, and mining equipment, where their ability to handle combination loads while withstanding harsh environmental conditions ensures reliable operation under continuous heavy loading. Aerospace and defense applications employ highly specialized slewing bearings in radar systems, telescope mounts, and weapon platforms, where precision manufacturing and exceptional reliability are paramount despite relatively lower load requirements.

The transportation industry utilizes slewing bearings in vehicle turntables, ferry loading ramps, and railway maintenance equipment, leveraging their compact design and high load capacity to maximize payload space while ensuring operational safety. Marine applications include shipboard cranes, hatch cover mechanisms, and submarine periscope systems, where corrosion resistance and reliability in saltwater environments become critical selection factors. Medical equipment manufacturers incorporate miniature slewing bearings in CT scanner gantries and surgical robot arms, where smooth, precise rotation directly impacts diagnostic quality and procedural success.

Important Considerations for Slewing Bearing Selection and Use

| Consideration | Description | Impact of Incorrect Selection |

|---|---|---|

| Load Analysis | Precise calculation of all applied loads including axial forces, radial forces, moment loads, and any combination loads that may occur during operation. Dynamic factors for shock loads must be included. | Catastrophic failure through raceway brinelling, rolling element fracture, or ring cracking. Underestimated loads can cause premature bearing failure within 10-20% of expected lifespan. |

| Rotation Requirements | Analysis of rotational speed, acceleration/deceleration requirements, and precision needs including runout tolerance and backlash specifications. | Excessive speed can cause lubrication failure and overheating. Inadequate precision affects system accuracy. High acceleration demands require special consideration of inertia effects. |

| Environmental Conditions | Evaluation of operating temperature range, presence of contaminants, exposure to corrosive elements, and potential moisture intrusion. | Standard seals fail in contaminated environments, leading to abrasive wear. Standard materials corrode in chemical exposures. Temperature extremes affect lubrication performance and material properties. |

| Installation Constraints | Assessment of available space, mounting surface flatness requirements, alignment tolerances, and access for maintenance. | Improper mounting surface preparation causes ring distortion and premature failure. Inadequate space compromises sealing effectiveness and maintenance access. |

| Gear Requirements | Determination of gear quality needed, tooth hardness, precision requirements, and proper mating with pinion gear including backlash control. | Inadequate gear quality causes premature wear and noise. Improper backlash leads to impact loading and tooth fracture. Insufficient hardness reduces gear life significantly. |

| Lubrication System | Selection of appropriate lubrication type (grease or oil), viscosity grade, additive package, and re-lubrication interval based on operational conditions. | Incorrect lubricant leads to increased friction, overheating, and premature wear. Inadequate lubrication intervals cause metal-to-metal contact and catastrophic failure. |

| Service Life Expectancy | Calculation of required L10 life based on application criticality, desired maintenance intervals, and overall equipment design life. | Underestimated life requirements lead to premature failure and unplanned downtime. Overestimation results in overspecified bearings with unnecessary cost and weight penalties. |

Frequently Asked Questions (FAQ) About Slewing Bearings

Q1: What is the difference between a slewing bearing and a conventional rotary bearing?

A: Slewing bearings are specifically designed to handle combination loads (axial, radial, and moment loads simultaneously) while conventional rotary bearings typically handle primarily radial OR axial loads. Slewing bearings feature integrated mounting holes and often include gear teeth, making them complete functional components rather than just bearing elements. They're engineered for slow rotational speeds and oscillating movements rather than continuous high-speed rotation.

Q2: How long can I expect a slewing bearing to last in normal service?

A: Service life varies significantly based on application conditions, but properly specified and maintained slewing bearings typically achieve L10 lives of 25,000-100,000 operating hours. For equipment operating 8 hours daily, this translates to 8-30 years of service. Actual life depends on load severity, environmental conditions, maintenance practices, and operational factors. Many bearings outlast the equipment they're installed in when properly maintained.

Q3: Can slewing bearings be repaired or must they be replaced when worn?

A: While slewing bearings are generally considered non-repairable components, certain wear items can be addressed. Seal replacement, re-lubrication, and gear tooth refurbishment are possible in some cases. However, raceway damage or ring cracking typically requires complete replacement. Some manufacturers offer refurbishment services for large, expensive bearings, but this is often not economically viable for standard-sized bearings.

Q4: How often should slewing bearings be lubricated?

A: Lubrication intervals depend on operational factors including speed, temperature, load, and environmental conditions. Typical recommendations range from 100-500 operating hours for heavy-duty applications in contaminated environments to 1,000-2,000 hours for cleaner, less demanding applications. The first re-lubrication should occur after the first 50-100 hours of operation to remove initial wear particles. Always follow manufacturer recommendations for specific applications.

Q5: What are the signs of slewing bearing failure?

A: Common indicators include increased rotational torque, audible noise during operation (clicking, grinding, or rumbling), visible rust or lubricant leakage, increased gear backlash, and visible pitting or brinelling on raceways. Regular monitoring of these parameters allows for planned replacement before catastrophic failure occurs. Vibration analysis and lubricant particle testing can provide early warning of developing issues.