Slewing Bearing Installation Guide Mastering Correct Procedures

What is Slewing Bearing

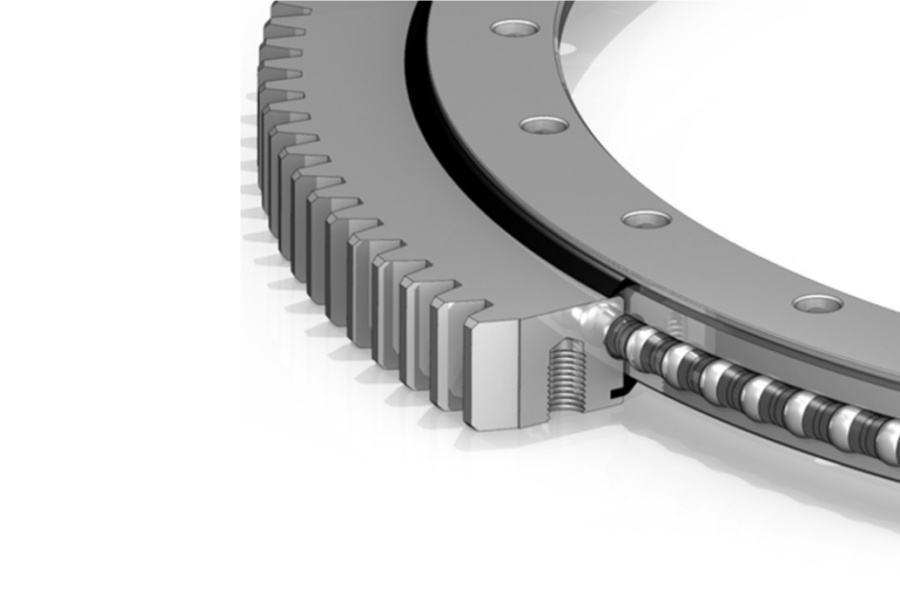

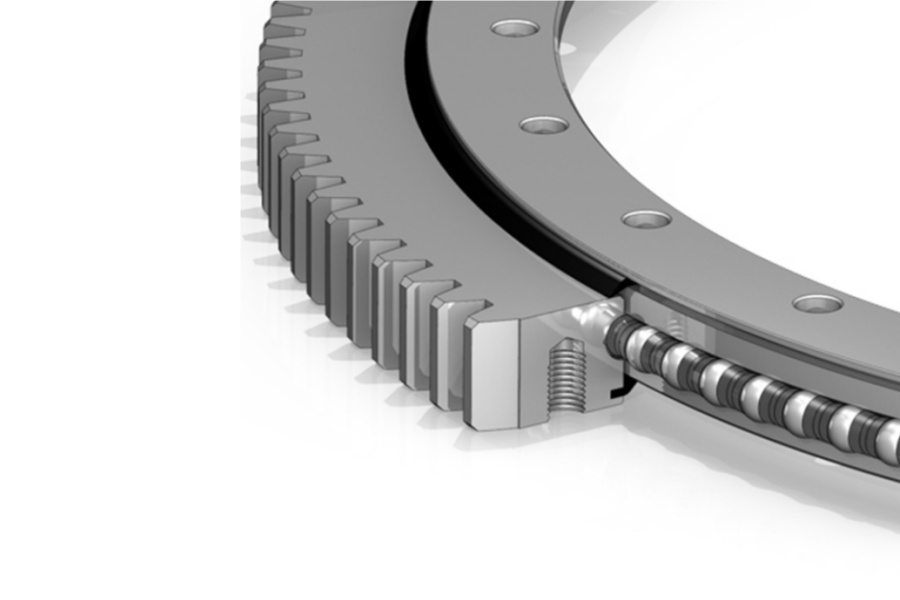

Slewing Bearing is a critical rotational component engineered to handle combined axial, radial, and moment loads in heavy machinery. Featuring integrated mounting holes and often gear teeth, it enables 360-degree rotation between structural sections in equipment like cranes, excavators, and wind turbines. Its hardened raceways and rolling elements (balls or rollers) demand meticulous installation to prevent premature wear, deformation, or catastrophic failure under operational stresses.

Step-by-Step Correct Installation Methodology

Pre-Installation Inspection & Surface Preparation

Verify Documentation: Cross-check bearing nameplate data (model, serial number) against purchase order and manufacturer’s certificate.

Visual & Functional Check: Inspect for transit damage (dents, seal tears). Manually rotate the bearing—movement must be smooth without binding or grinding noises.

Mounting Surface Requirements:

Flatness tolerance: ≤ 0.3 mm/m² (measured with precision straightedge).

Surface roughness: ≤ Ra 6.3 μm (machined finish, no milling marks or burrs).

Cleanliness: Remove oil, grease, weld spatter, or corrosion using non-abrasive solvents.

Bearing Positioning & Bolt Tightening Protocol

Soft Zone Orientation: Identify the "S" marked soft zone (untempered area from heat treatment). Position it within the non-load or minimal-load sector (e.g., opposite the crane boom).

Gap Elimination:

Place bearing horizontally on the mounting surface using nylon slings.

Insert a 0.05 mm feeler gauge at 100 mm intervals.

If gaps >0.1 mm exist, install annealed copper shims (0.2–1.0 mm thickness) beneath gaps—never use paint or putty.

Bolt Specifications:

Use only new ISO 898-1 Grade 10.9 or 12.9 bolts.

Apply Molykote G-Rapid Plus or equivalent anti-seize lubricant to threads.

Fit hardened steel flat washers (HRC 40–45); elastic washers are strictly prohibited.

Tightening Sequence:

Tighten bolts in a star pattern at 30% → 60% → 100% of final torque in three stages.

Final torque value: 70–80% of bolt yield strength (e.g., 1,150 N·m for M30 10.9 bolt).

Use calibrated hydraulic torque wrench ±3% accuracy.

Gear Meshing Adjustment (For Gear-Mounted Bearings)

Identify Hardened Zone: Locate gear teeth painted green/blue (indicating maximum hardness zone).

Set Backlash:

Place 0.03–0.04 x module thickness feeler gauge between pinion and marked teeth.

Example: Module 10 → backlash = 0.3–0.4 mm.

Adjust pinion position until slight drag is felt on the gauge.

Validation: Rotate bearing manually ≥ 3 full revolutions. Binding, uneven resistance, or noise indicates incorrect meshing.

Post-Installation Verification & Commissioning

Debris Removal: Clean raceways, gears, and adjacent components using lint-free cloths.

Interference Check: Verify 50 mm clearance between bearing and hydraulic lines/cabling.

Lubrication: Inject lithium complex EP-2 grease into gear teeth until excess emerges.

Test Run:

Energize system at ≤ 10% max RPM for 5 rotations.

Monitor torque (should be stable ≤ 15 N·m for 1m-diameter bearings).

Listen for abnormal sounds (e.g., metallic grinding = misalignment).

Inspect bolt heads for paint marker shifts (indicating loosening).

Critical Slewing Bearing Characteristics

Load Capacity: Axial: 500–10,000 kN; Radial: 250–5,000 kN; Moment: 1,000–30,000 kN·m

Gear Specifications: Ground teeth (DIN 6–7 accuracy), 55–60 HRC hardness, module 6–30.

Sealing: Triple-lip seals with HNBR/FKM compound (IP66 rating).

Material: Forged 42CrMo4/50Mn steel, through-hardened to 55±2 HRC.

Precision: Raceway radial runout ≤ 0.05 mm.

Industrial Applications

Mobile Cranes: Truck-mounted, all-terrain, and rough-terrain cranes (Liebherr, Grove)

Excavators: 20–800-ton mining and hydraulic excavators (CAT 6090, Komatsu PC8000)

Wind Turbines: Yaw systems (3–8 MW onshore/offshore)

Aerial Platforms: 40m+ boom lifts (JLG, Genie)

Medical LINACs: Radiation therapy gantries

Price Determinants

Size & Load Rating: Bearings >2m OD cost 2.5–4x more than 1m units.

Gear Quality: Ground gears add 25–35% cost vs. milled gears.

Material: 42CrMo4 alloy premium: 20–30% over 50Mn steel.

Precision Class: ISO P5 tolerance: +15–20% vs. P6.

Sealing: IP67 multi-lip seals: +10–15%.

Certification: EN 15048 bolt certification: +8–12%.

Supplier of slewing bearings

LYRADRIVE delivers ISO 9001-certified slewing bearings with installation-specific engineering support. Their PRO-TORQ™ bolt tensioning kits and FEA-based mounting surface analysis ensure optimal load distribution. Global service teams provide on-site installation supervision and backlash optimization, reducing commissioning failures by 40%.