Preventing Damage to Large Machinery Slewing Bearings

What is Truck Crane Slewing Bearing

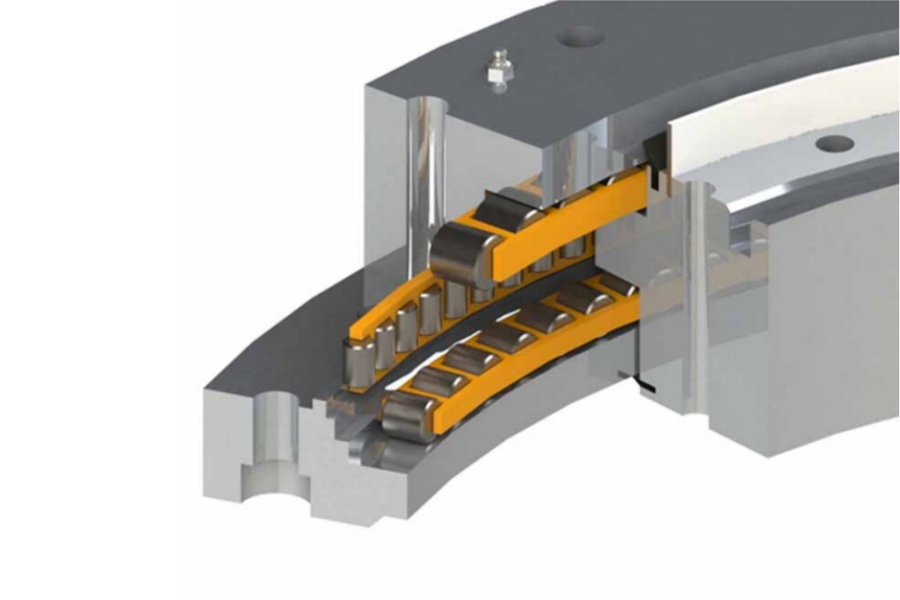

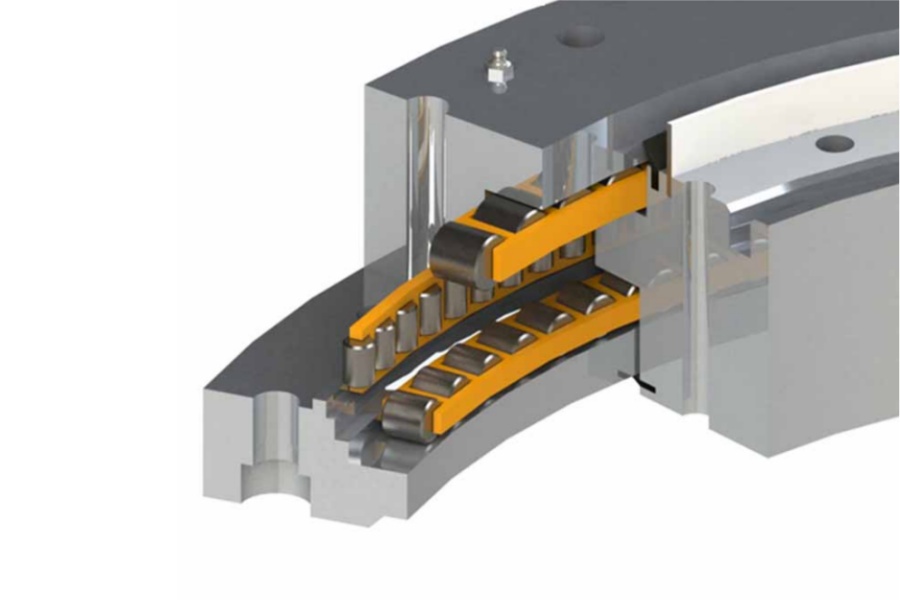

Truck Crane Slewing Bearing is a specialized high-capacity rotational bearing system enabling 360-degree movement between a truck crane’s upper structure (boom, cab, counterweights) and its carrier chassis. Engineered to withstand extreme axial loads from lifted loads, radial loads during boom extension, and dynamic moment loads during slewing operations, it integrates hardened raceways, gear teeth for drive mechanisms, and pre-drilled mounting holes. Its robust construction (typically forged 42CrMo4/50Mn steel) and precision-ground rolling elements ensure reliable performance under cyclical stress, variable weather, and high-impact job sites.

Key Strategies to Prevent Slewing Bearing Failure

Reinforce Mounting Structures

Increase Base Plate Thickness: Upgrade chassis and turntable mounting plates to 25–40mm thickness (vs. standard 15–20mm) using Q355B/ST52-3 high-tensile steel.

Stiffen Support Structures: Add radial reinforcement ribs (≥12mm thickness) around bolt circles to minimize elastic deformation under load.

Precision Machining: Ensure mounting surface flatness ≤0.3mm/m² and roughness ≤Ra 6.3μm to eliminate point loading.

Bolt Preload Control: Use hydraulic tensioners to achieve consistent 70–80% yield strength preload on 10.9/12.9 grade bolts with hardened flat washers.

Optimize Safety Factors in Design

Increase Bearing Height: Design 15–20% taller cross-sections (e.g., 180mm height for 2,000mm OD bearings) to enhance moment load resistance.

Maximize Rolling Elements: Raise roller/ball count by 10–15% (e.g., 140+ rollers in three-row designs) while maintaining >95% raceway contact.

Upsize Rolling Elements: Use rollers ≥40mm diameter in heavy-duty cranes to distribute contact stress below 2,200 MPa.

Advanced Cage Design: Implement segmented brass cages (CuZn25Al6) or solid steel cages to prevent skewing under shock loads.

Enhance Manufacturing Precision

Controlled Heat Treatment:

Reduce induction quenching speed to 80–120°C/s (vs. standard 150–200°C/s) for deeper case hardening (≥8mm depth).

Achieve surface hardness 58–62 HRC with core toughness 35–40 HRC to resist micro-pitting.

Raceway Integrity: Maintain grinding tolerances ≤0.025mm and surface finish ≤Ra 0.4μm.

Residual Stress Management: Implement cryogenic treatment (-196°C) post-quenching to minimize internal stresses.

Operational Safeguards

Load Monitoring: Install LMI systems to enforce 85% SWL (Safe Working Load) limits.

Seal Integrity: Use triple-lip seals with FKM compounds (IP67 rating) and automated grease injection every 50 operating hours.

Corrosion Protection: Apply zinc-nickel electroplating (20–30μm) or Dacromet coatings to raceways.

Critical Features of Truck Crane Slewing Bearings

Dynamic Load Ratings: Axial: 1,500–12,000 kN; Radial: 800–6,000 kN; Moment: 3,000–45,000 kN·m

Gear Integration: Ground spur/helical gears (DIN 6–8 accuracy) with 56–60 HRC hardness.

Sealing Systems: Triple-labyrinth seals with wear-resistant FKM/SBU lip materials.

Material Science: Vacuum-degassed 42CrMo4 steel, ultrasonic-tested for inclusions.

Precision Metrics: Raceway runout ≤0.05mm; gear radial wobble ≤0.1mm.

Industrial Applications

Mobile Cranes: 25–1,200-ton truck-mounted cranes (e.g., Liebherr LTM, Grove GMK)

Aerial Work Platforms: Rotational systems for 40m+ boom lift

Drilling Rigs: Foundation drilling equipment (e.g., Bauer BG, Soilmec SR)

Forestry Equipment: Grapple loaders and timber harvesters

Military Vehicles: Recovery crane systems

Price Determinants

Size & Capacity: Bearings >2.5m OD cost 2.8–3.5x more than 1m units.

Material Premium: 42CrMo4 alloy adds 25–30% cost vs. 50Mn steel.

Precision Upgrades: DIN 6 gear grinding increases cost 35% vs. DIN 8 milling.

Protection: Zinc-nickel plating adds $800–$1,200 per bearing.

Certification: EN 15048 bolt certification adds 8–12%.

Customization: Non-standard PCD bolt patterns incur 15–25% surcharge.

Supplier of Heavy-Duty Bearing

LYRADRIVE engineers ISO 9001/EN 15048-certified truck crane slewing bearings with proprietary SURE-TRAC™ hardening technology achieving 8–12mm case depth at 60±1 HRC. Their in-house FEA simulation optimizes reinforcement strategies for specific crane models while integrated load sensors enable predictive maintenance. Global technical support includes on-site bolt tensioning verification and customized regreasing protocols.