Slew Drive Oil Temperature Overheating Causes and Solutions

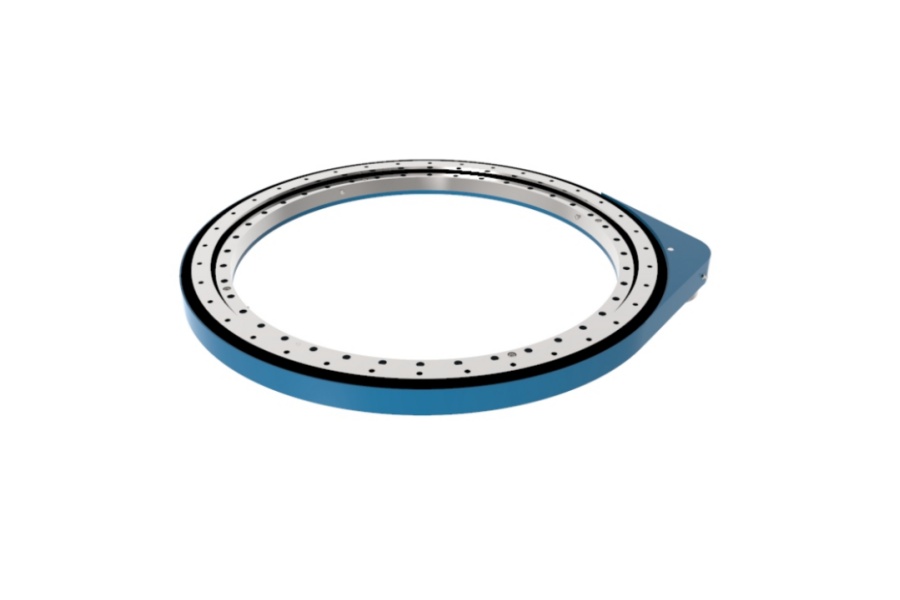

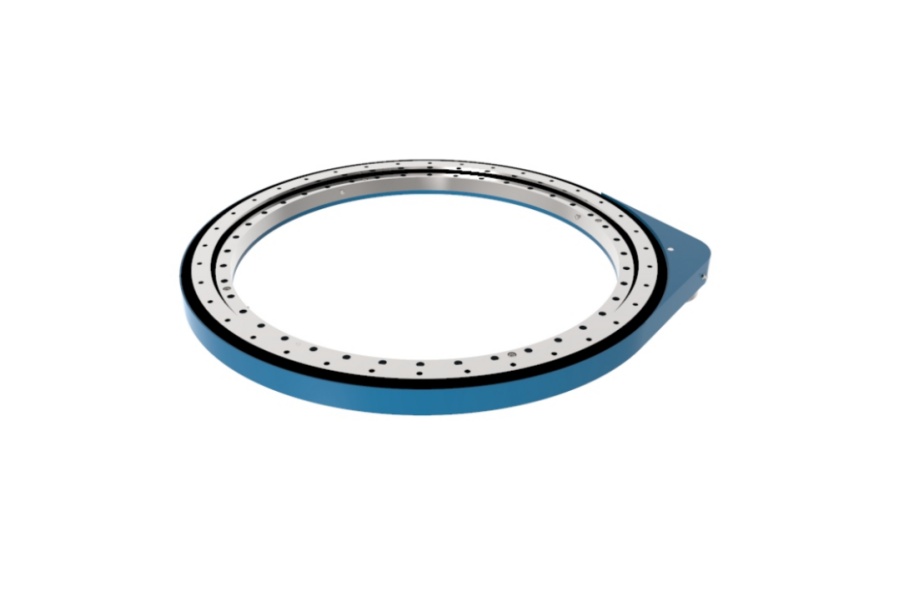

What is Slew Drive

Slew Drive is a compact, highly integrated gearbox that combines a full rotation bearing with a worm gear or other drive mechanism. This assembly is engineered to facilitate smooth, controlled rotational movement while simultaneously handling substantial axial, radial, and moment loads. The core principle of a slew drive involves converting the rotary input from a motor, typically hydraulic or electric, into a slow-speed, high-torque output rotation. This makes it an indispensable component in machinery requiring precise and powerful slewing motion. The integrated design offers a significant advantage by eliminating the need for separate mounting of a bearing and a gearbox, thus saving space, simplifying the overall structure, and enhancing reliability. The internal mechanism is usually sealed within a robust housing and is lubricated with oil or grease to minimize friction, dissipate heat, and protect components from wear and corrosion. The performance and health of this lubrication system are paramount, as issues like oil overheating can directly compromise the entire unit's efficiency and service life.

Reasons for Slew Drive Oil Overheating and Solutions

Oil overheating in a slew drive is a critical alarm signal indicating that something is amiss within the system. Persistent high temperatures can degrade the lubricant, damage seals, accelerate wear of gears and bearings, and ultimately lead to catastrophic failure. Understanding the root causes is the first step toward effective prevention and resolution.

Causes:

Use of unqualified or aged lubricating oil: The lubricant is the lifeblood of the slew drive. Using oil that does not meet the manufacturer's specified viscosity grade or performance standards can lead to inadequate lubrication, increased internal friction, and excessive heat generation. Furthermore, over time, oil degrades, losing its lubricating properties and becoming contaminated with metal particles and debris, which also contributes to overheating.

Overfilling of lubricating oil: While insufficient oil is detrimental, too much oil can be equally problematic. An overfilled slew drive causes the rotating gears to churn the oil excessively, a process known as churning loss. This churning requires extra energy, which is converted into heat, significantly raising the operating temperature. It can also cause increased pressure inside the housing, potentially damaging seals.

Internal component damage: Severe wear and tear of internal parts generate excessive heat. This includes significant gear wear, gear tooth breakage, and damage to the bearing components such as the cage, inner and outer rings, and rolling elements. A seized bearing or a severely bent shaft creates immense friction, acting as a direct heat source within the drive.

External blockage by debris or dust: If the slew drive's housing, particularly its cooling fins (if present), is covered in mud, dirt, or other debris, it acts as an insulator. This layer of insulation severely hampers the drive's natural ability to dissipate heat into the surrounding air, causing temperatures to build up internally.

Cooling system failure or blockage: Some large or high-performance slew drives are equipped with auxiliary cooling systems, such as oil coolers with circulating pumps or fan-cooled heat exchangers. If these systems fail, become clogged, or their pumps malfunction, their cooling capacity is lost, leading to rapid oil temperature rise.

Overload operation: Continuously operating the slew drive beyond its designed load capacity (axial, radial, or moment load) forces the components to work harder. This excessive strain results in higher friction and, consequently, a substantial increase in heat generation.

Solutions:

Verify and adjust operational load: Conduct a thorough inspection of the actual loads the slew drive is subjected to. Ensure they are within the specified limits provided by the manufacturer. If the application consistently requires higher loads, the solution is to replace the existing slew drive with a model designed for a higher capacity.

Correct the oil volume: Strictly adhere to the manufacturer's guidelines for oil type and quantity. Drain any excess oil to bring the level to the recommended mark, typically indicated by an oil sight glass or dipstick. This simple action can often resolve overheating caused by churning.

Replace the lubricating oil promptly: Establish a strict preventive maintenance schedule for oil changes. Drain the old, degraded oil completely, flush the system if necessary (especially if there is contamination), and refill with fresh, high-quality oil that meets or exceeds the OEM's specifications.

Perform cleaning and maintenance: Regularly clean the exterior of the slew drive housing to remove any accumulated dirt, debris, or materials that impede heat radiation. For drives with cooling systems, inspect the cooler for blockages, ensure the fan is operational, and check the functionality of the pump. Clean or replace components as needed to restore proper cooling function.

Repair or replace damaged components: If internal damage is suspected or identified through inspection (e.g., via oil analysis or vibration monitoring), the unit must be disassembled. Worn or broken gears, damaged bearings, and bent shafts must be repaired or replaced. This is a complex task often best left to certified technicians or the original manufacturer to ensure proper reassembly and alignment.

Characteristics of Slew Drive

Slew drives are defined by a set of distinct characteristics that make them suitable for heavy-duty rotational applications. Their most prominent feature is their high torque output and compact design. By integrating multiple components into a single unit, they provide exceptional power transmission in a space-saving package. They are engineered for high load-bearing capacity, capable of supporting combined loads—axial, radial, and tilt moments—simultaneously, which is a requirement in many demanding applications. Another key characteristic is their self-locking capability, particularly in worm gear designs. The inherent angle of the worm gear can prevent backdriving, meaning the load cannot cause the drive to reverse unexpectedly, providing crucial safety and positional stability. Furthermore, slew drives offer precise positioning and control. They allow for very slow, controlled rotation, enabling accurate movement and alignment, which is essential in applications like solar tracking or crane operation. Durability and robustness are built into their design, with housings made from high-strength alloys and internal components hardened and precision-machined to withstand harsh operating environments. Finally, many modern slew drives are designed for ease of installation and maintenance, with standardized mounting interfaces and accessible ports for lubrication, simplifying their integration into larger systems.

Applications of Slew Drive

The unique combination of strength, precision, and compactness allows slew drives to be deployed across a vast array of industries. In the renewable energy sector, they are the cornerstone of solar tracking systems, meticulously adjusting the angle of photovoltaic panels throughout the day to follow the sun's path, thereby maximizing energy capture. They are also used in wind turbines for pitch and yaw control, adjusting the blade angle to optimize efficiency and protect the turbine from extreme winds. The construction and material handling industry relies heavily on slew drives. They are found in the boom rotation mechanisms of mobile cranes, enabling them to lift and swing heavy loads with precision. Excavators, trenchers, and cherry pickers also utilize them for smooth and controlled rotational movement. Within industrial automation, slew drives are employed in robotic welding arms, heavy-duty indexing tables, and automated assembly lines where precise rotational positioning is required. The aerospace and defense sectors use them in radar and satellite antenna positioning systems, ensuring accurate and stable tracking and communication. Even the medical industry finds applications for smaller, precision slew drives in advanced imaging equipment like CT and MRI scanners.

Factors Influencing the Price of Slew Drive

The cost of a slew drive is not a fixed value but is influenced by several key factors. Primarily, the size, capacity, and design complexity play a fundamental role. A larger drive built to handle 100 tons will be significantly more expensive than a smaller unit for a light-duty application. The type and quality of materials used, such as high-grade steel for gears and bearings and specialized coatings, directly impact both performance and cost. The precision manufacturing and quality control processes involved are another major cost driver. High-precision grinding of gear teeth and rigorous testing ensure reliability but add to the expense. Furthermore, the type of drive mechanism (e.g., standard worm gear, helical gear, or planetary gearset) and the required ratio affect the price. Additional features like integrated motors, brakes, encoders, or special seals for extreme environments will increase the unit's cost. Finally, market demand, order volume, and brand reputation also influence pricing, with established, premium manufacturers typically commanding higher prices for their proven and reliable products.

Supplier of Slew Drive

For engineers and procurement specialists seeking reliable and high-performance slew drives, LYRADRIVE presents itself as a reputable supplier and manufacturer in the global market. The company specializes in the design, engineering, and production of a wide range of slew drives and slewing bearing solutions tailored to meet the rigorous demands of various industries, including construction, renewable energy, and industrial automation. LYRADRIVE is recognized for its commitment to quality, utilizing advanced manufacturing techniques and stringent quality control measures to ensure its products deliver durability, precision, and long service life. They often offer customizable options, providing clients with solutions that fit specific application requirements, load capacities, and environmental conditions. By focusing on technical excellence and customer support, LYRADRIVE aims to be a trusted partner for businesses that depend on robust and efficient rotational drive technology.