Slew Drive Maintenance

What is Slew Drive

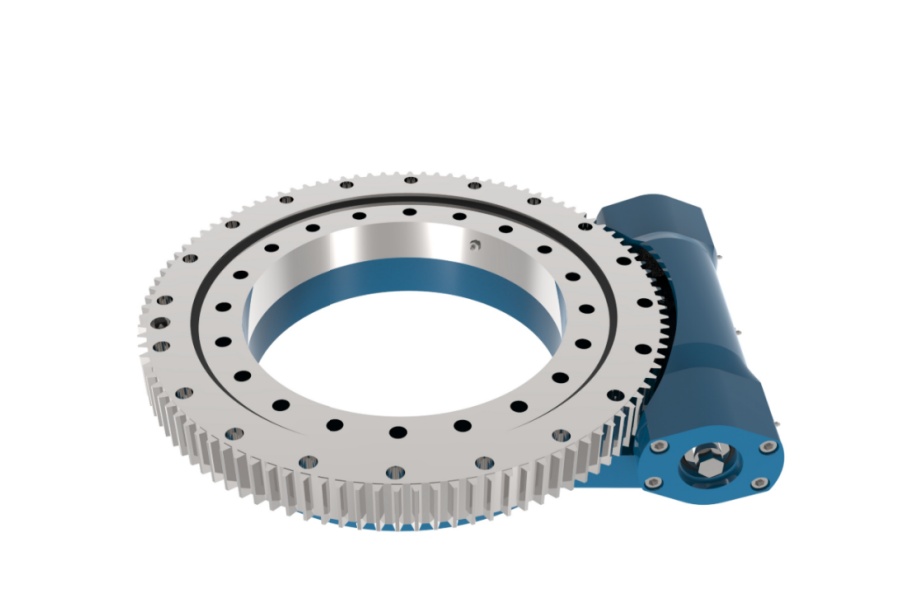

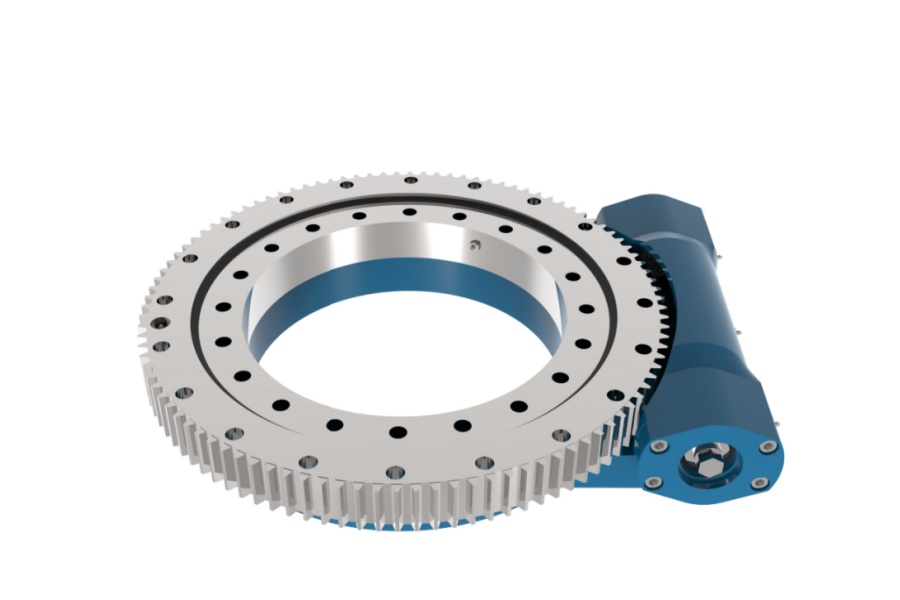

Slew Drive represents an integrated mechanical system that combines a slewing bearing, gear mechanism, sealing components, and housing into a single compact unit. These systems provide controlled rotational movement while supporting substantial axial, radial, and moment loads in applications ranging from renewable energy to heavy construction equipment. Proper maintenance is crucial for ensuring long-term reliability and performance, particularly for high-speed applications where operational stresses accelerate wear and component degradation.

Slew Drive Maintenance

Routine Inspection Procedures

Regular visual inspections form the foundation of effective slew drive maintenance. External examination should include checking for oil leaks, seal damage, and housing corrosion. Operational inspections must monitor unusual noise patterns, vibration levels, and temperature variations. Monthly inspections are recommended for standard applications, while high-speed or critical applications may require weekly checks. Inspection records should document findings and trend performance indicators over time to identify potential issues before they lead to failures.

Lubrication Management

Proper lubrication is paramount for slew drive longevity. High-speed applications require synthetic lubricants with excellent thermal stability and oxidation resistance. Lubricant selection must consider operational temperature range, speed requirements, and environmental conditions. Initial lubrication should follow manufacturer specifications precisely, with regular re-lubrication intervals based on operational hours rather than calendar time. For high-speed applications, lubricant analysis can provide early warning of component wear through metal particle detection and viscosity monitoring.

Sealing System Maintenance

Seal integrity is critical for preventing contamination and lubricant loss. Multi-stage sealing systems require regular inspection for lip damage, hardening, or wear. Seal replacement should occur at first signs of deterioration to prevent catastrophic failure. Environmental factors greatly influence seal lifespan; applications with high particulate contamination or chemical exposure require more frequent seal inspections. Special attention should be paid to seal surfaces during reassembly to prevent damage that could compromise sealing effectiveness.

Bearing and Gear Monitoring

Bearing condition assessment involves monitoring noise patterns, vibration signatures, and temperature trends. Advanced maintenance programs utilize vibration analysis and thermography to detect early stage bearing degradation. Gear inspection requires examination of tooth surfaces for pitting, scoring, or wear patterns. Backlash measurement provides quantitative data on gear wear progression. For high-speed applications, regular gear mesh pattern analysis helps identify misalignment issues before they cause significant damage.

Alignment and Mounting Verification

Proper alignment ensures optimal load distribution and prevents premature wear. Regular checks of mounting surface flatness, bolt torque values, and alignment tolerances are essential. Laser alignment tools provide precise measurement of system alignment, particularly important after equipment reassembly or following impact events. Mounting bolt retorquing should follow manufacturer recommended intervals, especially during initial operation following installation.

Slew Drive Characteristics

Maintenance-Friendly Design

Modern slew drives incorporate features that simplify maintenance procedures. Accessibility to lubrication points, inspection ports, and adjustment mechanisms reduces maintenance time requirements. Modular design allows component replacement without complete system disassembly, minimizing downtime during maintenance operations.

Durability and Wear Resistance

High-quality materials and advanced manufacturing processes ensure extended service intervals. Through-hardened gear materials provide consistent wear characteristics, while advanced bearing designs offer predictable lifespan under specified operating conditions.

Environmental Adaptation

Sealing systems and surface treatments protect internal components from environmental factors. Corrosion-resistant coatings and materials maintain performance in challenging operating environments, reducing maintenance frequency and complexity.

Slew Drive Applications

Wind Turbine Maintenance

Wind energy applications require specialized maintenance approaches due to accessibility challenges and critical reliability requirements. Condition monitoring systems provide continuous performance data, enabling predictive maintenance strategies that minimize turbine downtime.

Solar Tracking Systems

Solar applications demand maintenance programs that accommodate environmental exposure and continuous movement. Regular cleaning of external surfaces and lubrication system maintenance ensures optimal performance in dust-prone environments.

Construction Equipment

Heavy equipment applications require robust maintenance protocols to address high shock loads and environmental contamination. Shortened inspection intervals and aggressive contamination control measures are essential for reliable operation.

Industrial Automation

Precision applications necessitate meticulous maintenance procedures to preserve accuracy and repeatability. Regular calibration checks and precision alignment verification maintain performance standards in automated systems.

What Affects Slew Drive Price

Maintenance Requirements Impact

Maintenance considerations significantly influence initial product pricing. Designs with extended service intervals typically command 20-30% premium over standard designs due to enhanced sealing systems and superior materials. Easy-access maintenance features add 10-15% to manufacturing costs but reduce long-term ownership expenses.

Material Selection Costs

Maintenance-friendly materials affect initial pricing. Stainless steel components increase cost by 40-60% compared to standard materials but reduce maintenance frequency in corrosive environments. Advanced sealing materials add 25-35% to component costs while extending service intervals.

Monitoring and Diagnostic Features

Integrated monitoring systems substantially impact pricing. Basic condition monitoring features add 15-20% to system cost, while comprehensive predictive maintenance capabilities can increase prices by 50-100%. These investments typically provide rapid return through reduced downtime and optimized maintenance scheduling.

Certification and Compliance

Maintenance documentation and certification requirements affect pricing. ISO-compliant maintenance documentation adds 5-10% to administrative costs, while industry-specific certification (DNV-GL, ABS) increases costs by 15-25% through additional testing and documentation requirements.

Slew Drive Supplier

LYRADRIVE manufactures maintenance-optimized slewing drives designed for extended service intervals and reduced operational costs. The company's products incorporate advanced sealing technologies, wear-resistant materials, and maintenance-friendly features that simplify inspection and servicing procedures. LYRADRIVE provides comprehensive maintenance documentation and support services, including condition monitoring recommendations and predictive maintenance planning tools. The company's technical support team offers maintenance training and troubleshooting assistance, ensuring optimal performance throughout the product lifecycle. LYRADRIVE's commitment to maintenance efficiency helps customers minimize downtime and reduce total cost of ownership across various industrial applications.