Environmental Adaptability of Slew Drives

What is Slew Drive

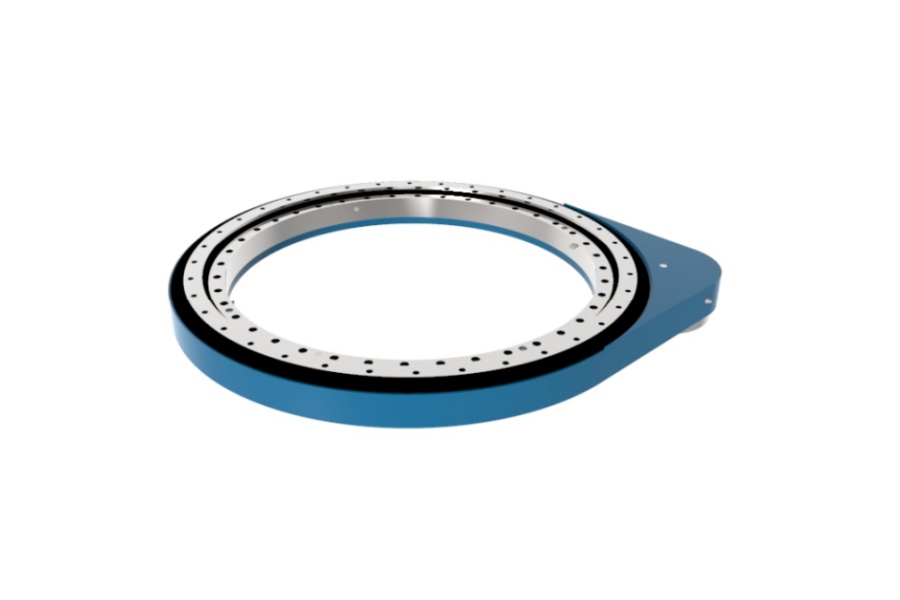

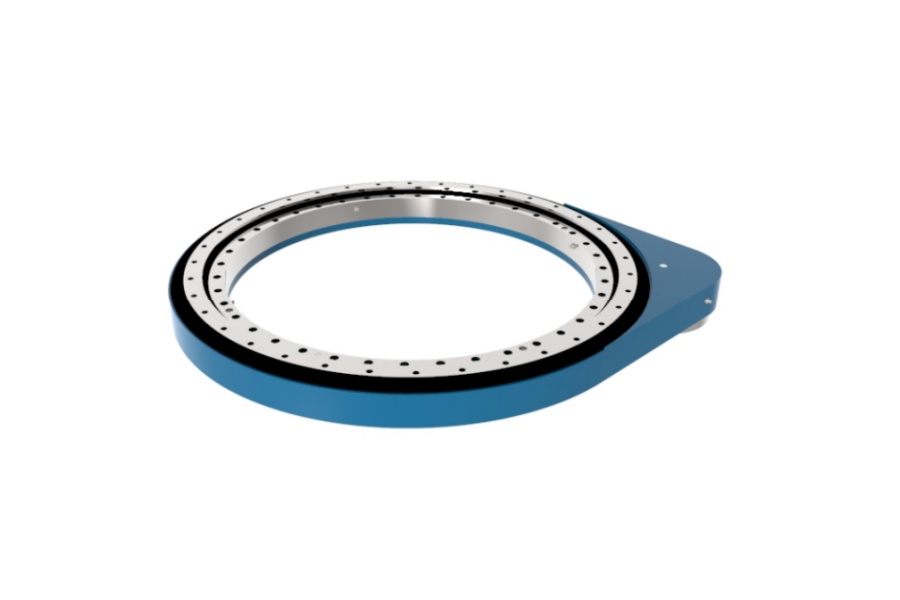

Slew Drive is an integrated mechanical system that combines a slewing bearing, worm or spur gearing, sealing mechanisms, and often mounting features into a single compact unit. Designed to provide controlled rotational movement under significant loads, these drives excel in transmitting high torque while supporting combined axial, radial, and moment loads. Their versatility makes them suitable for numerous industrial applications where environmental challenges must be overcome without compromising performance or service life.

Environmental Adaptability of Slew Drives

Operating Temperature Range

Slew drives are engineered to perform reliably across extreme temperature spectrums. Specialized lubricants maintain viscosity stability from -40°C to 120°C, while material selection ensures structural integrity throughout this range. High-temperature applications utilize synthetic lubricants and heat-resistant seals, while low-temperature environments require frost-resistant greases and materials resistant to brittle fracture. Thermal management systems, including cooling fins and heat dissipation pathways, are incorporated for applications generating substantial internal heat during operation.

Contamination Resistance

Advanced sealing technologies protect slew drives from environmental contaminants. Multi-stage sealing systems combine labyrinth seals with triple-lipped radial seals to exclude dust, water, and abrasive particles. Corrosion protection is achieved through surface treatments such as zinc-nickel plating and stainless steel components. For chemically aggressive environments, specialized seal materials like Viton or PTFE provide resistance against oils, solvents, and acidic compounds while maintaining sealing integrity.

Spatial Constraints and Installation Flexibility

Modern slew drives offer exceptional adaptability to space-limited applications. Compact design methodologies allow for reduced envelope dimensions without sacrificing performance. Modular mounting options include flange, foot, and cartridge configurations, enabling integration with existing machinery. Customizable output options and mounting orientations provide additional flexibility for challenging installation scenarios. The drives are designed for straightforward maintenance access, with lubrication points and adjustment features positioned for easy serviceability.

Robustness Against Mechanical Stress

Heavy-duty construction enables operation in high-vibration and shock-load environments. Reinforced gear teeth undergo shot peening and case hardening processes to enhance fatigue resistance. Anti-backlash designs maintain precision under variable loading conditions. Specialty bearing arrangements distribute loads evenly, preventing localized stress concentrations even during impact loading events.

Slew Drive Characteristics

Exceptional Load Capacity

Slew drives combine high torque transmission with substantial load-bearing capabilities. Through optimized gear geometry and bearing arrangements, they simultaneously handle axial loads exceeding 500 kN, radial loads up to 300 kN, and moment loads beyond 200 kN·m. This multi-directional load capacity makes them ideal for applications requiring both rotation and structural support.

Precision Motion Control

Despite their robust construction, slew drives offer precise positioning capabilities. Precision-ground gearing provides angular accuracy within ±0.1°, while anti-backlash mechanisms ensure repeatable positioning. Integrated encoder options enhance positioning precision for applications requiring exact movement control.

Maintenance-Friendly Design

Long service intervals and straightforward maintenance characterize modern slew drives. Re-lubrication systems allow for easy maintenance without disassembly, while wear indicators provide visual confirmation of component condition. Modular construction enables quick replacement of individual components, minimizing downtime during maintenance procedures.

Slew Drive Applications

Renewable Energy Systems

Solar tracking systems utilize slew drives for precise panel orientation, operating in desert heat, coastal salt spray, and high-altitude conditions. Wind turbine yaw and pitch systems rely on heavy-duty drives capable of withstanding extreme weather, temperature fluctuations, and continuous operation.

Construction Machinery

Excavators and cranes employ slew drives in dusty, high-impact environments where reliability is critical. These applications demand resistance to shock loads, weather exposure, and continuous operation under full load conditions.

Marine and Offshore Equipment

Deck cranes, winches, and positioning systems use corrosion-resistant slew drives capable of operating in saltwater environments. Special coatings and stainless steel components prevent corrosion while maintaining performance in high-humidity conditions.

Industrial Automation

Robotic welding cells and material handling systems utilize precision slew drives in environments contaminated with metallic dust and cooling fluids. Enclosed designs and protective coatings ensure reliable operation despite exposure to industrial contaminants.

What Affects Slew Drive Price

Environmental Protection Requirements

The cost of environmental protection measures significantly impacts pricing. Standard IP54 protection adds approximately 15-20% to base cost, while IP67 protection increases cost by 30-40%. Explosion-proof certifications (ATEX, IECEx) can double the unit price due to additional testing and certification requirements.

Material Selection

Material upgrades for environmental resistance substantially affect pricing. Stainless steel construction increases cost by 60-80% compared to carbon steel, while specialized coatings add 15-25% to the base price. High-performance seal materials such as Viton or Kalrez increase cost by 20-35%.

Temperature Management Systems

Integrated heating systems for low-temperature operation add 15-20% to the unit cost, while active cooling systems for high-temperature applications increase price by 25-40%. Specialized lubricants for extreme temperatures add 10-15% to the overall cost.

Certification and Testing

Environmental testing and certification processes contribute significantly to final pricing. Salt spray testing certification adds 10-15%, while full environmental testing suite (temperature, humidity, vibration) increases cost by 20-30%. Industry-specific certifications (DNV-GL, ABS) add 15-25% to the base price.

Slew Drive Supplier

LYRADRIVE manufactures industrial-grade slewing drives engineered for challenging operating environments. The company's products feature advanced sealing systems, corrosion-resistant materials, and robust construction methodologies that ensure reliable performance in extreme conditions. LYRADRIVE offers technical support for environmental adaptation requirements, providing customized solutions for specific operating conditions and application challenges. The company's quality management system ensures consistent performance across all environmental ratings, with comprehensive testing validating performance under specified operating conditions.