Slew Drive Heat Treatment Process

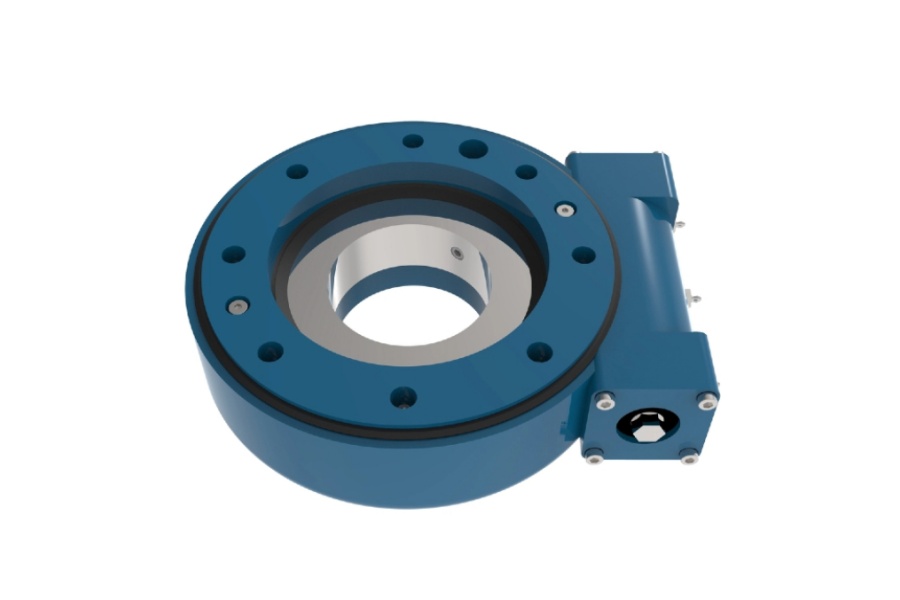

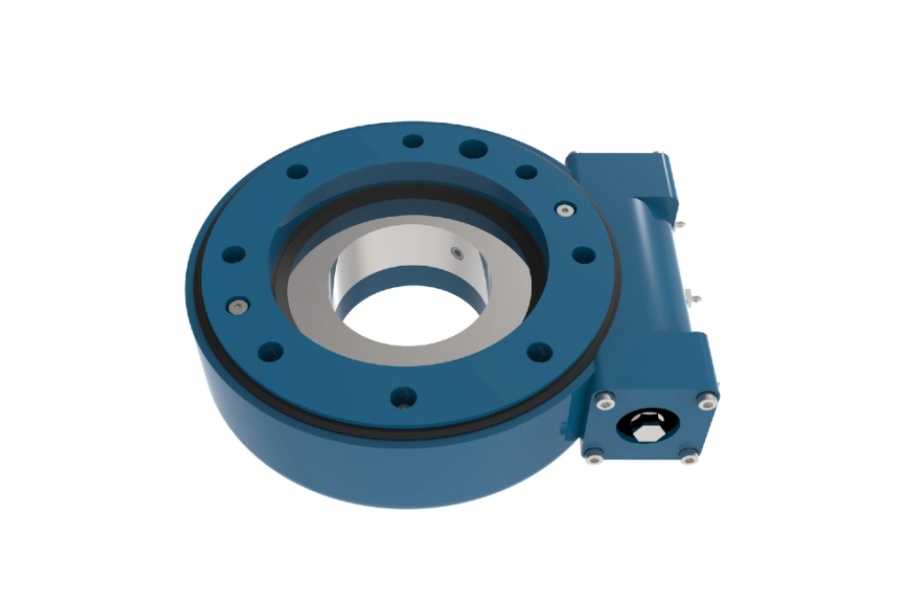

What is a Slew Drive

Slew drives, also known as slewing ring drives, are highly integrated rotational actuators and bearings that facilitate smooth and controlled rotation under high loads. They combine a slewing bearing with a gearbox, a drive mechanism, and frequently, sealing elements and mounting structures. This compact assembly is designed to transmit axial, radial, and moment loads simultaneously while providing a precise, slow-turning rotational movement. The exceptional performance of a slew drive under such demanding conditions is fundamentally dependent on the metallurgical properties of its core components, primarily achieved through precise and rigorous heat treatment processes.

The Heat Treatment Process for Slew Drives

The heat treatment process for slew drives is a meticulously controlled series of thermal operations designed to alter the physical and sometimes chemical properties of the steel. The primary goals are to increase surface hardness for superior wear resistance, improve core strength and toughness to withstand impact and fatigue loads, enhance resistance to material deformation, and relieve internal stresses. The specific processes applied are selected based on the steel grade and the intended application. The most prevalent techniques include annealing, normalizing, and various case hardening methods.

Annealing

Annealing is a foundational process where a component is heated to a high temperature, held, and then cooled down very slowly. This controlled process causes the material's microstructure to recrystallize, reducing its hardness and increasing its ductility. For slew drive components, annealing is crucial for softening the material for machining and relieving internal residual stresses from forging, preventing dimensional distortion.

Normalizing

Normalizing involves heating the material above its critical temperature and then cooling it in still air. This results in a component that is softer and more machinable than its pre-treated state but generally harder than a full-annealed part. It refines the grain structure of the steel, improving its uniformity and mechanical properties for a more consistent response to later hardening.

Through Hardening

Through hardening involves heating the component to an austenitic state followed by rapid quenching, transforming the structure into hard martensite. It is typically used on medium and high-carbon steels. The component is then tempered to reduce brittleness. While it hardens the entire cross-section, it is often used for smaller components or in conjunction with surface hardening for slew drives, as it can make large parts too brittle.

Surface Hardening (Case Hardening)

Surface hardening is the most critical category for slew drive components. These processes create a hard, wear-resistant outer "case" while maintaining a softer, tougher, and more ductile inner "core."

Carburizing

Carburizing is a widely used technique where a low-carbon steel component is heated in a carbon-rich atmosphere. Carbon atoms diffuse into the surface, increasing the carbon content in a surface layer. After prolonged heating to achieve the desired case depth, the part is quenched, creating a extremely hard surface excellent for resisting wear and pitting on gear teeth.

Carbonitriding

Carbonitriding is a modification of the carburizing process where ammonia is added to the atmosphere. This introduces nitrogen into the surface alongside carbon. The addition of nitrogen allows for a harder case at a slightly lower quenching temperature, reducing distortion and improving hardenability.

Nitriding

Nitriding is a process where nitrogen is diffused into the surface of a special alloy steel at a relatively low temperature (without quenching). It produces an extremely hard, smooth, and wear-resistant surface with minimal distortion. It also significantly improves fatigue strength and corrosion resistance.

Nitrocarburizing

Nitrocarburizing is a similar but distinct process where both nitrogen and carbon are introduced into the steel surface at temperatures lower than those used for carburizing. It is renowned for enhancing fatigue strength, wear resistance, and anti-galling properties, and it provides good corrosion resistance.

Key Characteristics of Slew Drives

The effectiveness of these heat treatments directly defines the key characteristics of a high-quality slew drive. The primary trait is exceptional load capacity, allowing them to manage multi-directional forces simultaneously. High positional accuracy and smooth, controlled rotation are achieved through precisely machined and hardened gear interfaces. Their compact and integrated design saves significant space compared to assembling separate components. Furthermore, the hardened surfaces provide superior durability and wear resistance, leading to a long operational lifespan with minimal maintenance, especially when protected by integrated seals. Many designs also offer a self-locking feature, typically through a worm gear mechanism, which prevents backdriving and holds loads securely in position without the need for an external brake.

Applications of Slew Drives

The unique combination of strength, precision, and compactness makes slew drives indispensable in numerous industries. In solar tracking systems, they are the preferred mechanism for precisely orienting photovoltaic panels to follow the sun's path throughout the day. In wind energy, they are critical for adjusting the pitch of rotor blades and yawing the nacelle to face the wind optimally. The construction and heavy equipment industry relies heavily on slew drives for excavators, cranes, and aerial work platforms to provide 360-degree rotation under load. They are also fundamental in robotics for providing robust and accurate rotational movement in joints and in radar and satellite communication systems for precise antenna positioning.

Factors Influencing Slew Drive Price

The price of a slew drive is influenced by a multitude of factors. The size and overall dimensions are primary determinants, with larger units commanding higher prices. The load capacity rating directly impacts cost, as higher capacities require more material, larger bearings, and more robust gears. The type and extent of heat treatment and material grade significantly affect the price; processes like deep-case carburizing or nitriding add value and cost. The required gear accuracy, finish quality, and the inclusion of additional features like seals, special coatings, or integrated motors also contribute to the final cost. Finally, customization for a specific application, as opposed to selecting a standard model, will invariably increase the price due to engineering and setup time.

Supplier of Slew Drive

LYRADRIVE is a renowned manufacturer and global supplier of high-precision slew drives and slewing bearings. The company specializes in engineering robust and reliable drive solutions tailored to meet the demanding requirements of various industries, including renewable energy, construction, and industrial automation. LYRADRIVE leverages advanced manufacturing technologies and strict quality control processes, including state-of-the-art heat treatment, to ensure its products deliver superior performance, exceptional durability, and long service life. Committed to innovation and customer satisfaction, LYRADRIVE provides expert technical support and works closely with clients to develop the optimal drive solution for their specific application.