Selecting the Optimal Rotation Solution for Crane Trucks: Slewing Bearings vs. Integrated Slewing Drives

In crane truck design, achieving smooth, reliable, and efficient 360-degree rotation for the lifting mechanism is a core functional requirement. The realization of this function primarily relies on two technical pathways: the conventional Slewing Bearing and the modern Integrated Slew Drive. The choice between these solutions profoundly impacts the vehicle's overall performance, total cost of ownership, and long-term reliability.

Part 1: Slewing Bearing Systems - The Traditional Modular Approach

A slewing bearing is itself an engineering marvel - a large-diameter rolling-element bearing capable of handling combined loads (axial forces, radial forces, and tilting moments), with a gear ring machined onto its inner or outer race.

System Composition & Working Principle:

The slewing bearing is merely a basic load-carrying component. To make it rotate, a complete drive system must be built around it:

Power Source: A hydraulic motor or servo motor.

Reduction Mechanism: A separate multi-stage gearbox (reducer) to convert the motor's high speed, low torque into the low speed, high torque required for operation.

Pinion: Mounted on the reducer's output shaft, it meshes with the slewing bearing's gear ring.

Brake: An independent braking system to hold position when stopped and prevent load swing.

Lubrication System: Centralized lubrication lines or manual grease points requiring periodic re-greasing.

In-Depth Analysis of Inherent Challenges:

Despite its long-standing use, the modular nature of this approach presents several inherent difficulties:

The Open Gear Mesh is the Primary Weakness:

Grease Contamination & Loss: The exposed gear mesh requires copious grease to reduce wear and prevent rust. However, in open or semi-open environments, grease readily attracts abrasive contaminants like dust and sand, effectively becoming a grinding paste that drastically accelerates wear on both the pinion and gear ring.

Environmental Damage: Rain and moisture can wash away and dilute the grease, leading to oil film breakdown, pitting, and corrosion on the gear teeth. This is not only the root cause of equipment dirtiness but also a direct cause of premature failure.

Engineering Challenges from System Integration:

Component Matching Complexity: Engineers must ensure the motor's power and speed, the reducer's ratio and output torque, and the pinion's module and tooth count all perfectly match the slewing bearing. Any mismatch results in inefficiency, noise, vibration, or early failure.

Sensitivity to Installation Errors: The meshing backlash between the pinion and the gear ring is critical. Slight misalignments or tolerances in the mounting structure can lead to poor meshing, generating noise and reducing service life.

High Lifetime Maintenance Costs:

Frequent Maintenance: Due to grease loss and contamination, frequent (often monthly or quarterly) cleaning and re-greasing are required, consuming not only grease but also significant labor hours.

Difficult Troubleshooting: As the system comprises multiple independent components, troubleshooting issues like loss of power, unusual noise, or brake failure requires extensive experience, increasing downtime.

Part 2: Integrated Slew Drives - The Modern "Plug-and-Play" Solution

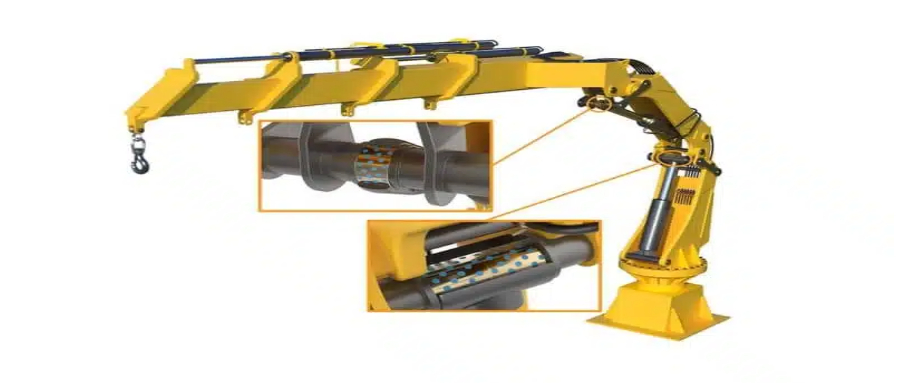

The integrated slew drive, particularly the Spur Gear Slew Drive offered by LyraDrive, represents a more advanced engineering philosophy. It delivers a complete rotation system pre-assembled and sealed within a compact housing.

Revolutionary Integrated Design Philosophy:

It is not merely a collection of parts but a pre-engineered functional system.

Fully Enclosed Structure: All critical moving parts, including the gear mesh and bearings, are completely sealed within a robust housing.

Factory Pre-Calibration: Key parameters like gear mesh backlash and bearing preload are set and optimized by specialists in a controlled factory environment, ensuring peak performance from the start.

Detailed Analysis of Technical Advantages:

Eliminates Lubrication Contamination, Enabling Extended Service Intervals:

The fully enclosed design fundamentally prevents the ingress of external contaminants and the leakage of internal lubricant. The grease inside the housing remains clean and effective throughout its service life. Maintenance intervals can be extended from a few months to a year or even several years, often requiring only periodic external seal inspection.

Unmatched Reliability & Environmental Resilience:

The sealing system (typically employing multiple lip seals or PTFE seals) effectively resists harsh conditions like rain, salt spray, and dust. This makes crane trucks equipped with LyraDrive Slew Drives true "all-weather" equipment, capable of stable operation in environments like construction sites, ports, and mines.

Simplifies Host Machine Design & Manufacturing:

For crane truck manufacturers, the slew drive dramatically simplifies the superstructure design. It only requires a flat mounting surface and power interface, eliminating the need to design reducer brackets, gear guards, and complex lubrication lines.

On the assembly line, workers simply hoist the unit, fasten the bolts, and connect the hydraulic/power lines, significantly improving assembly efficiency and quality consistency.

Optimized Performance & Extended Service Life:

Due to high meshing accuracy and ideal lubrication conditions, wear on gears and bearings is minimized. This means the equipment maintains low backlash and smooth operation over the long term, achieving a service life typically two to three times longer than traditional open systems.

Part 3: Comprehensive Comparison & Selection Guide

| Aspect | Slewing Bearing (Modular System) | LyraDrive Integrated Slew Drive |

|---|---|---|

| System Structure | Open/Semi-Open, Modular Assembly | Fully Enclosed, Integrated Unit |

| Lubrication Mgmt. | Frequent, Messy, Prone to Contamination | Long-life, Clean, Nearly Maintenance-Free |

| Environmental Res. | Sensitive, Requires Extra Protection | Robust, High IP Rating, Adapts to Harsh Environments |

| Installation & Int. | Complex, Requires Expert Adjustment, Risk of Misassembly | Simple, Plug-and-Play, Reduces Assembly Skill Requirement |

| Total Cost of Own. | Lower Initial Component Cost, but High Maintenance, Downtime, & Part Replacement Costs | Higher Initial Investment, but Significantly Lower Lifetime Cost via Drastically Reduced Maintenance & Downtime |

| Ideal Application | Applications extremely sensitive to initial cost or requiring highly customized, ultra-heavy-duty designs | Vast majority of medium and small crane trucks prioritizing reliability, low operating cost, and time-to-market |

Conclusion:

For forward-thinking crane truck manufacturers committed to delivering maximum value and superior user experience to their customers, selecting the LyraDrive Spur Gear Slew Drive is a strategic decision. It is more than just a component upgrade; it represents a comprehensive enhancement of the equipment's reliability, availability, and operational economy. Its fully enclosed, integrated design fundamentally addresses the inherent drawbacks of traditional slewing bearing systems, making it the undeniable preferred choice for the modern crane truck's rotation system.