How Should the Slew Drive Be Lubricated Correctly?

What is Slew Drive?

A slew drive, also known as a slewing drive, is a compact, high-efficiency power transmission component. It integrates a slewing bearing with a precision gearbox (typically featuring a worm gear mechanism) into a single, robust unit. This design enables it to handle simultaneous axial, radial, and moment loads while providing high reduction ratios for smooth, controlled rotational motion. Its compact, sealed, and all-in-one structure makes it a fundamental building block for machinery requiring precise and powerful rotation.

How Does Slew Drive Work?

The core principle of a slew drive is based on the worm gear mechanism. When the input shaft, connected to the motor, rotates the worm (a threaded screw), it engages with and drives the worm wheel (a gear integrated into the slewing bearing's outer ring or inner ring). This engagement converts the high-speed input from the motor into a powerful, low-speed, high-torque output rotation of the bearing ring. A key feature is its ability to achieve self-locking under certain gear ratios, preventing back-driving and holding the load securely in position without the need for an external brake.

Application of Slew Drive

Slew drives are incredibly versatile and are the backbone of motion in many industries. Common applications include:

Solar Tracking Systems: Precisely positioning solar panels to follow the sun's path.

Wind Turbines: Adjusting the pitch of blades for optimal wind capture and control.

Construction Machinery: Enabling the rotation of excavator booms, crane booms, and man-lifts.

Material Handling: Powering the rotation of robotic arms, stackers, and palletizers.

Satellite & Radar Antennas: Providing accurate and stable rotational positioning for communication and surveillance equipment.

Why is Proper Lubrication Essential for Slew Drives?

Proper lubrication is not just a maintenance task—it is the fundamental factor determining the performance, efficiency, and lifespan of a slew drive. Understanding its role in detail helps prevent costly failures and unscheduled downtime. The core functions of lubrication in a slew drive include:

Minimizing Wear and Friction: The worm gear mechanism and slewing bearing components operate under high contact pressure. Lubrication forms a durable film that separates moving metal surfaces, preventing direct contact. This reduces abrasive wear, micro-pitting, and surface fatigue, especially under heavy loads and slow-speed rotation.

Heat Dissipation: Continuous operation, especially under high torque or in cyclic duty applications, generates significant heat. Lubricants absorb and transfer heat away from critical contact zones, such as the worm-gear interface and bearing raceways. Without adequate lubrication, heat buildup can lead to thermal expansion, loss of gear mesh accuracy, accelerated oil degradation, and ultimately, seizure of components.

Corrosion and Contaminant Protection: Slew drives often operate outdoors or in harsh environments where moisture, dust, salt, and chemicals are present. A high-quality grease acts as a physical barrier, coating internal surfaces to prevent rust and corrosion. It also helps seal out fine abrasives and particulate contaminants that could act as grinding compounds, accelerating wear.

Vibration and Noise Dampening: Proper lubrication ensures smooth transmission of motion by filling microscopic gaps between gear teeth and rolling elements. This results in quieter operation, reduced vibration, and improved positioning accuracy—critical in applications like solar tracking or precision radar systems.

Extended Operational Life: Regular and correct lubrication directly impacts the total cost of ownership. A well-lubricated slew drive can operate reliably for tens of thousands of hours, whereas poor lubrication practices can lead to premature failure within a fraction of that time, requiring expensive replacements and production losses.

In short, lubrication is not merely an add-on—it is integral to the mechanical integrity and functional reliability of the slew drive system.

Factors to Consider for Slew Drive Lubrication

Selecting and applying the correct lubricant requires careful evaluation of several interrelated factors. An inappropriate choice can negate the benefits of lubrication and even cause damage. The key considerations are:

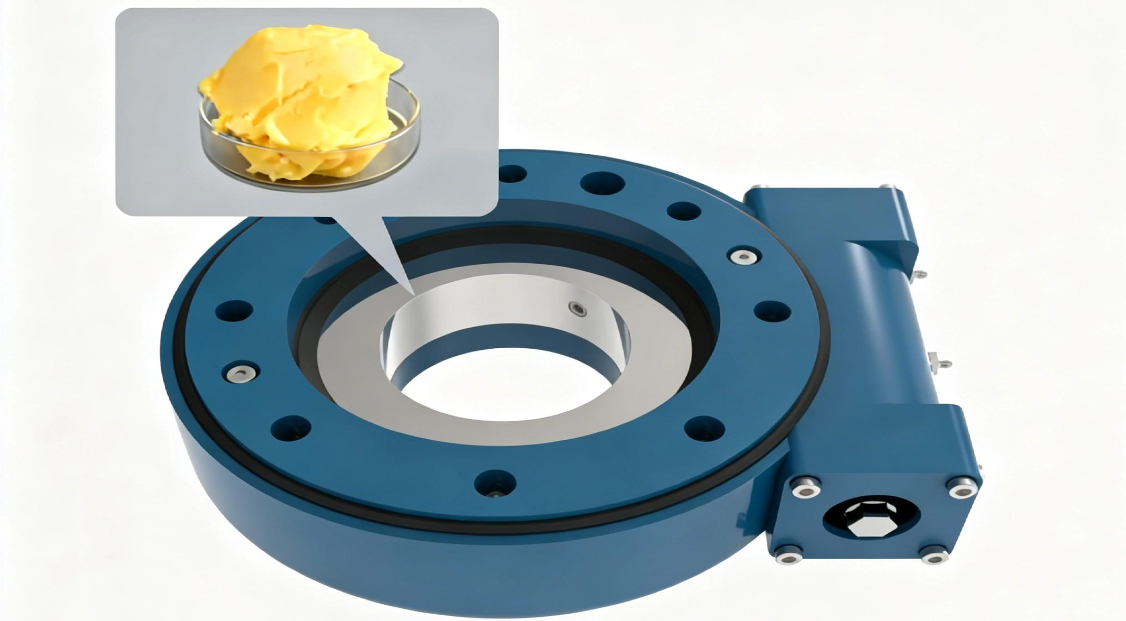

Lubricant Type and Specification: Most slew drives are lubricated with high-viscosity, extreme-pressure (EP) grease. Important properties to evaluate include:

NLGI Grade: Typically, grade 1.5 to 2 is used for most operating temperatures. Softer greases (lower NLGI) may be needed for cold climates.

Base Oil Viscosity: Must be sufficiently high to maintain the lubricating film under high pressure and low-speed conditions.

Thickener Type: Lithium complex or calcium sulfonate greases offer good mechanical stability, water resistance, and high-temperature performance.

Additives: Look for anti-wear (AW), rust inhibitors, and anti-oxidation additives. For oscillating movements, greases with polymer additives to prevent “channeling” are beneficial.

Operational Environment:

Temperature Range: Synthetic greases are recommended for temperatures below -30°C or above 120°C. Ensure the grease has a wide operating range if the drive experiences significant temperature swings.

Exposure to Moisture/Washdown: In wet environments (e.g., marine, agricultural, or food processing), use greases with strong water resistance and anti-washout properties, often labeled as “water-resistant” or “marine grade.”

Dust and Debris: In dusty conditions (construction, mining), a tackier, adhesive grease helps seal out contaminants.

Load and Motion Characteristics:

Static vs. Dynamic Loads: High static loads require greases with high load-carrying capacity (e.g., containing molybdenum disulfide or other solid lubricants).

Oscillating vs. Continuous Rotation: Oscillating motion does not redistribute grease evenly; therefore, a grease designed for such motion is essential to prevent dry spots.

Shock Loads: Applications with frequent start-stop or impact loads benefit from greases with enhanced film strength and anti-shock additives.

Manufacturer’s Guidelines and Sealing System: The slew drive’s internal design, seal type, and internal cavity volume dictate the grease quantity and regreasing intervals. Always prioritize the OEM’s specifications, as they are based on specific design calculations and validation tests.

How Should the Slew Drive Be Properly Lubricated?

A structured, step-by-step approach ensures that lubrication is effective, safe, and prolongs the drive’s life. Follow this detailed procedure for initial filling, routine maintenance, and condition assessment.

Step 1: Preparation and Safety

Ensure the machinery is powered off and locked out to prevent accidental rotation. Clean the grease fittings (zerks), relief ports, and surrounding areas thoroughly using a lint-free cloth and degreaser. This prevents dirt from being forced into the drive during lubrication.Step 2: Selecting the Correct Lubricant

Use only the grease type specified in the LyraDrive manual or one that is technically equivalent with confirmed compatibility. Never mix different grease types unless compatibility is verified.Step 3: Initial Lubrication (For New or Overhauled Drives)

If the drive is new and pre-greased from the factory, verify the filling level per the manual. Some applications may require additional grease before commissioning. For reassembled drives, apply a thin layer of grease to all gear teeth and bearing raceways before final assembly to ensure initial protection.Step 4: Routine Re-lubrication Procedure

Locate Ports: Identify the pressure port (for grease injection) and the relief/vent port (for old grease discharge). Some drives have multiple ports for uniform distribution.

Connect Grease Gun: Use a clean, calibrated grease gun fitted with the correct nozzle. Ensure the grease gun is loaded with the approved lubricant and purged of air.

Pump Grease Slowly: Inject grease in short, controlled strokes. Observe the relief port. Stop immediately when clean, new grease begins to emerge. This indicates the old, potentially degraded or contaminated grease has been purged.

Avoid Over-greasing: This is critical. Excessive grease increases internal pressure, which can blow out seals, cause overheating due to churning, and damage seal lips. If no relief port is present, inject the exact amount specified in the manual (usually in grams or ounces).

Clean Excess: After purging, clean any excess grease from the relief port to prevent attracting dirt.

Step 5: Determining Lubrication Intervals

The interval depends on operating hours, environmental severity, load cycles, and temperature. A typical baseline might be every 500-1000 operating hours under normal conditions. Severe Service Factors that shorten intervals include: Continuous operation 24/7, exposure to water, salt, or abrasive dust, frequent high shock loads, and ambient temperatures consistently above 80°C. Implement condition-based monitoring where possible. Regularly sample and inspect purged grease for signs of contamination (grit, water, metal particles) or degradation (discoloration, hardening).Step 6: Post-Lubrication Operation

Before returning to full operation, manually rotate the drive several times, if possible, to help distribute the new grease evenly across all contact surfaces. Monitor for any unusual noise, overheating, or leakage in the first few hours after re-lubrication.

Important Note: If a drive has been severely neglected or shows signs of failure (grinding noise, excessive backlash), re-lubrication alone may not restore it. A full inspection or overhaul may be necessary. By following this comprehensive process, you can ensure your slew drive receives the care it needs for reliable, long-term performance.

LyraDrive Can Provide the Right Lubrication Solution for You

LyraDrive is a professional one-stop slewing device manufacturer majored in design and development, customized production, sales and service on slewing bearings and slewing drives. The LyraDrive team has been deeply involved in the design, manufacturing and application of slewing drives, slewing bearings and worm gear drivesfor more than 15 years, majored in the design and manufacture SE series slewing drives, WE series slewing drives, SP series gear slewing drives.

We offer more than just standard products; our engineering team provides customized lubrication recommendations based on your unique application environment—be it extreme temperatures, corrosive offshore conditions, or dusty construction sites. By choosing LyraDrive, you get not only a reliable rotation solution but also the expert support to maintain it correctly. Let us help you ensure your machinery keeps turning smoothly.

FAQ on How to Lubricate a Slew Drive

Q: How often should I lubricate my slew drive?

A: There's no universal answer. Always refer to the LyraDrive operation manual for the recommended interval based on your model and standard operating conditions. Extreme conditions necessitate more frequent service.

Q: Can I use any high-pressure grease?

A: Not necessarily. Using an incompatible grease can compromise performance. Always use the type specified by the manufacturer to ensure chemical compatibility and optimal performance.

Q: What happens if I over-grease my slew drive?

A: Over-greasing can cause excessive internal pressure, leading to seal damage, grease leakage, and even overheating due to churning. Only lubricate until clean grease appears at the seal purge point.

Q: Do I need to clean out old grease before adding new?

A: In standard re-lubrication through the provided ports, the new grease purges the old grease out. A full clean-out and re-pack is typically only required during a major overhaul or if the grease is severely contaminated.