Conquering Extreme Loads: The Unyielding Power of the SP-H 0955 Heavy Duty Gear Slewing Drive

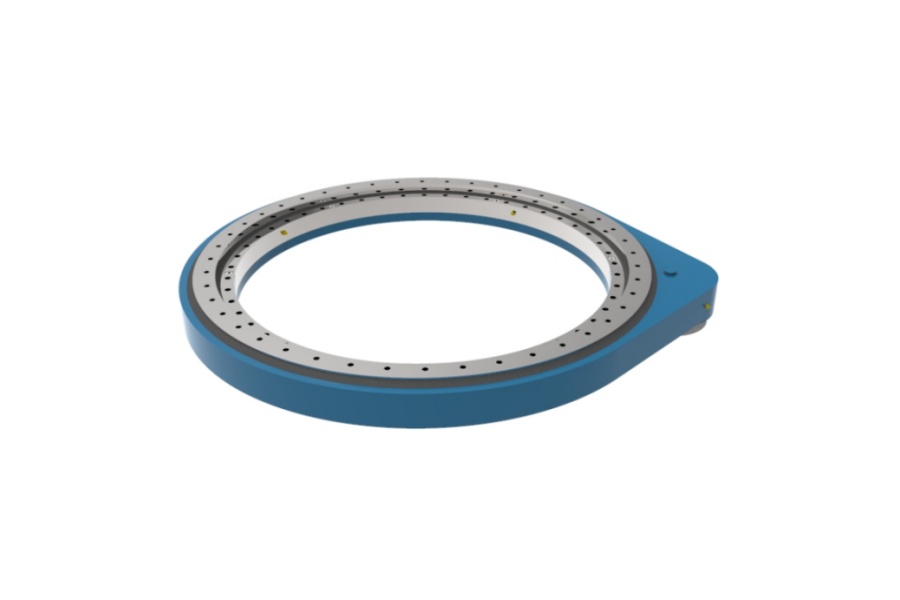

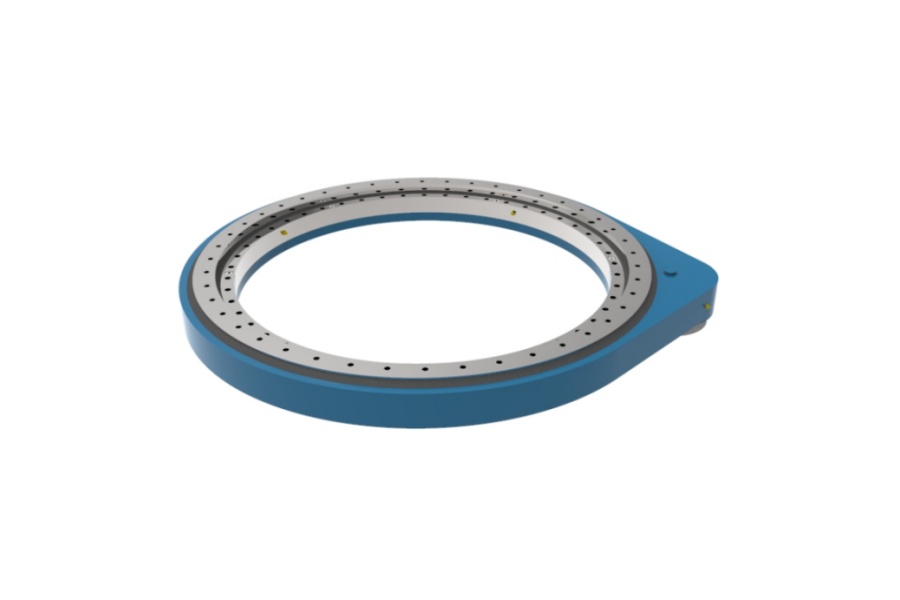

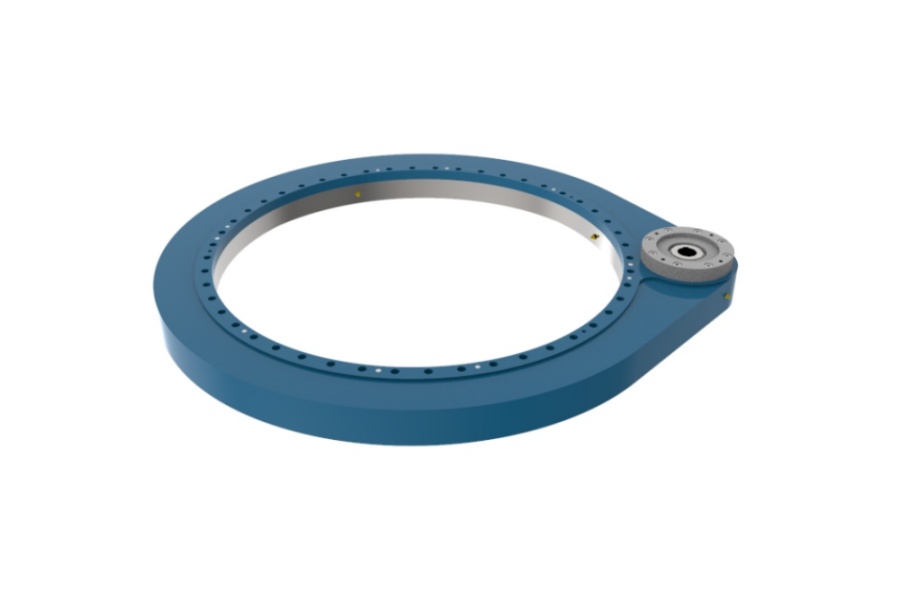

What is the Heavy Duty Gear Slewing Drive SP-H 0955?

At its core, the SP-H 0955 is a high-torque, precision rotational drive system integrating robust gearing, high-capacity bearings, and a sealed housing into a single, compact unit. Engineered far beyond standard slewing drives, it translates input power from a motor (hydraulic or electric) into controlled, high-force rotational movement for massive structures. Its defining characteristic lies in its exceptional load-bearing capacity – handling immense radial loads, axial loads, and tilting moments simultaneously. This makes it the cornerstone for applications where failure is not an option, demanding absolute reliability under continuous, severe stress. Precision machining ensures smooth operation and accurate positioning, critical for complex industrial tasks. Built with premium materials and advanced heat treatment processes, the SP-H 0955 is forged for endurance, resisting wear, deformation, and fatigue even after years of relentless operation in harsh conditions like mining, heavy construction, or offshore environments.

Ultra Heavy Duty Slewing Drive: The Next Tier of Resilience

While the SP-H 0955 epitomizes heavy-duty performance, the concept of "Ultra Heavy Duty" pushes boundaries even further. Ultra Heavy Duty slewing drives represent the pinnacle of slewing technology, designed for applications dwarfing standard heavy-duty requirements. Think colossal tunnel boring machines, gargantuan ship-to-shore cranes lifting hundreds of tons, or mammoth draglines excavating vast open-pit mines. These drives incorporate even larger, more robust gear sets crafted from specialized alloys, utilize extra-large diameter roller bearings (often multiple rows), and feature massively reinforced housings. Sealing systems become fortress-like, excluding even the finest abrasives and moisture under extreme pressure. Heat dissipation is paramount, often involving advanced lubrication systems and cooling strategies. Redundancy in critical components and enhanced monitoring capabilities are frequently integrated. The SP-H 0955, while formidable, sits firmly within the established Heavy Duty category; Ultra Heavy Duty solutions are bespoke behemoths engineered for the absolute extremes of scale and force, representing a distinct tier above.

Digital Twin Manual: Revolutionizing Operation and Maintenance

The integration of a Digital Twin Manual with a sophisticated component like the SP-H 0955 marks a transformative leap in asset management. This isn't merely a PDF version of a paper manual; it's a dynamic, virtual replica of the physical slewing drive, continuously fed with real-world operational data. Imagine a 3D interactive model accessible via tablet or computer on-site. Operators can virtually disassemble the drive, view exploded diagrams pinpointing every component, and access context-specific maintenance procedures instantly. The Digital Twin aggregates sensor data – temperature, vibration, lubrication levels, load cycles – comparing it against optimal performance benchmarks. It provides predictive maintenance alerts, flagging potential issues like abnormal wear patterns or lubrication degradation before they cause downtime. Troubleshooting becomes guided and efficient, overlaying diagnostic information onto the virtual model. For the SP-H 0955, this means maximizing uptime, optimizing maintenance schedules, preventing catastrophic failures, extending service life, and ensuring operators have the most current, actionable information at their fingertips, dramatically improving safety and operational efficiency.

Mining Solutions in the Chilean Copper Belt: A Crucible for Reliability

The Chilean Copper Belt, stretching hundreds of kilometers through the Atacama Desert, is the epicenter of global copper production. This environment presents a brutal proving ground for industrial machinery: extreme aridity, pervasive abrasive dust (often containing corrosive elements), high altitudes affecting cooling and combustion, intense solar radiation, seismic activity, and the relentless 24/7 demands of extracting and processing millions of tons of ore. Equipment downtime here translates directly into staggering financial losses. Slewing drives are mission-critical in numerous applications: massive stacker and reclaimer systems building and reclaiming ore stockpiles, high-capacity bucket-wheel excavators, rotary dumpers handling laden rail cars, and sophisticated conveyor systems snaking through the rugged terrain. Reliability isn't just desirable; it's an absolute necessity. The SP-H 0955 is engineered precisely for this crucible. Its sealed design combats the pervasive dust, premium materials resist corrosion, robust construction handles seismic stresses and massive dynamic loads, and its inherent durability ensures longevity despite the punishing cycles. Implementing such drives, coupled with advanced monitoring like Digital Twins, is key to achieving the operational continuity demanded by the world's most productive copper mines.

Key Features of the Heavy Duty Gear Slewing Drive SP-H 0955

The SP-H 0955 distinguishes itself through an array of meticulously engineered features designed for uncompromising performance. Exceptional Load Capacity is paramount, achieved through large-diameter, hardened and ground gear sets (often helical or double helical for smoothness and load sharing) and high-precision, multi-row roller bearings engineered to withstand combined radial, axial, and moment loads simultaneously. Robust Construction utilizes high-grade alloy steel forgings and castings, subjected to advanced heat treatment processes (like case hardening or induction hardening) for superior surface hardness and core toughness, resisting wear, pitting, and fatigue. Superior Sealing is critical; multi-layered labyrinth seals, often combined with high-performance radial shaft seals, create an impervious barrier against dust, water, mud, and other contaminants, even under high-pressure washdowns or immersion. Precision Engineering ensures smooth, low-vibration operation and accurate positioning, facilitated by meticulous manufacturing tolerances and optimized gear tooth profiles. High Efficiency is achieved through optimized gear geometry and premium bearing selection, minimizing energy loss and heat generation. Integrated Mounting simplifies installation with multiple, machined mounting surfaces (base and flange) offering flexibility for diverse applications. Versatile Drive Options accommodate various hydraulic motors or electric motors, providing flexibility in power source integration. Extended Service Life, a direct result of all the above features combined with proper maintenance, minimizes total cost of ownership despite the demanding operating conditions.

Diverse Applications Demanding the SP-H 0955

The SP-H 0955 finds its calling wherever immense loads meet the need for precise, reliable rotation. Mining & Mineral Processing is a primary domain, powering stackers, reclaimers, bucket-wheel excavators, ship loaders/unloaders, and crushing/screening equipment. Heavy Construction relies on it for robust crane superstructures (especially crawler, tower, and large mobile cranes), piling rigs, and tunnel boring machine components. Forestry Machinery utilizes these drives in heavy-duty harvesters and forwarders requiring high torque in rugged terrain. Material Handling benefits greatly in applications like large rotary car dumpers, heavy-duty industrial manipulators, and automated storage/retrieval systems handling massive loads. Renewable Energy employs them in critical components of large solar trackers and the yaw drives of multi-megawatt wind turbines. Port Equipment such as heavy-duty container cranes and bulk handling cranes depend on their reliability. Specialized Machinery in steel mills, foundries, and offshore applications also leverage the SP-H 0955's unique combination of strength, precision, and durability to perform critical rotational tasks under extreme stress.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0955 Pricing

The investment in an SP-H 0955 reflects its sophisticated engineering and premium construction. Several key factors drive its price point. Material Costs are significant, as it requires large volumes of high-grade alloy steels, specialized bearing steels, and advanced sealing materials. Manufacturing Complexity is substantial, involving precision forging/casting, multi-stage CNC machining of large components with tight tolerances, specialized heat treatment processes, and meticulous gear grinding. Bearing Cost is a major component, as the large-diameter, multi-row slewing bearings are complex and expensive items themselves. Load Capacity & Size directly correlate; higher torque ratings and larger physical dimensions inherently require more material and more complex manufacturing. Customization Level impacts price significantly. While standard models exist, modifications like special mounting interfaces, unique sealing configurations, specific surface treatments (e.g., offshore coatings), customized lubrication systems, or integrated sensors add cost. Drive Options (hydraulic vs. electric motor interface specifics) can influence the final price. Quality Assurance & Testing involves rigorous non-destructive testing (NDT), load testing, and performance verification, adding to the overall cost but ensuring reliability. Market Factors like raw material price fluctuations, energy costs, and global supply chain dynamics also play a role. While the initial purchase price is higher than standard drives, the SP-H 0955's extended lifespan, reduced downtime, and lower maintenance costs deliver a superior total cost of ownership (TCO) in demanding applications.

Supplier of Heavy Duty Gear Slewing Drive SP-H 0955

When the demands of your application push the boundaries of standard engineering, sourcing a critical component like the SP-H 0955 demands a supplier with proven expertise, unwavering commitment to quality, and global support. LYRADRIVE stands as a premier manufacturer and innovator in the field of high-performance slewing drives. Renowned for engineering excellence, LYRADRIVE doesn't just build slewing drives; they engineer solutions for the world's most challenging rotational motion problems. Their deep understanding of metallurgy, tribology, gear design, and bearing technology is embodied in every SP-H 0955 unit. Rigorous in-house manufacturing control, from forging and casting through precision machining, heat treatment, and final assembly, ensures consistent, uncompromising quality. LYRADRIVE invests heavily in R&D, constantly refining designs and materials to push performance and durability limits. Beyond the product, they offer comprehensive technical support, application engineering expertise to ensure optimal drive selection and integration, and responsive global after-sales service. Choosing LYRADRIVE means partnering with a leader whose reputation is built on delivering the robust, reliable, high-torque slewing drives like the SP-H 0955 that keep the world's most critical industries moving forward, even under the heaviest loads and in the harshest environments. Their commitment is to be your reliable drive partner, ensuring maximum uptime and productivity for your heavy-duty applications.