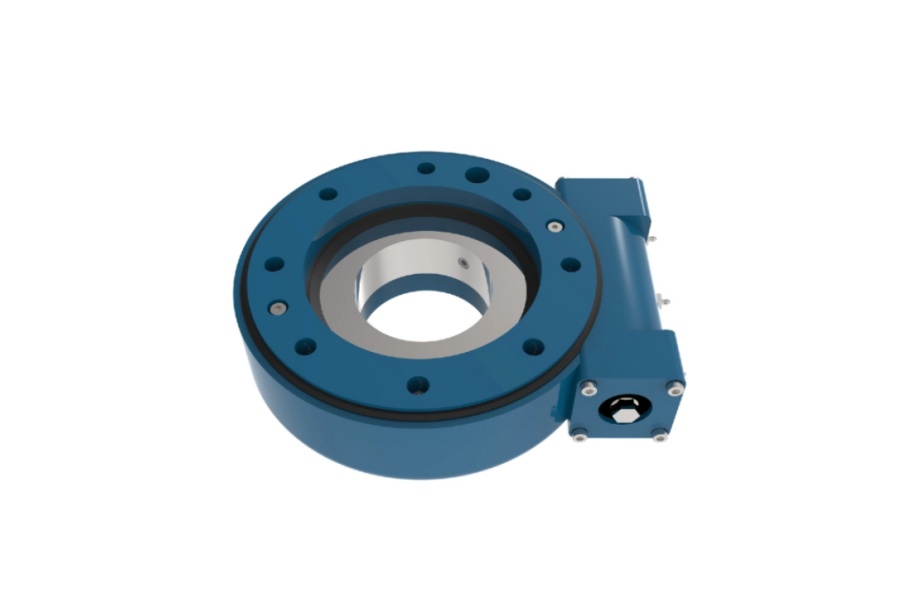

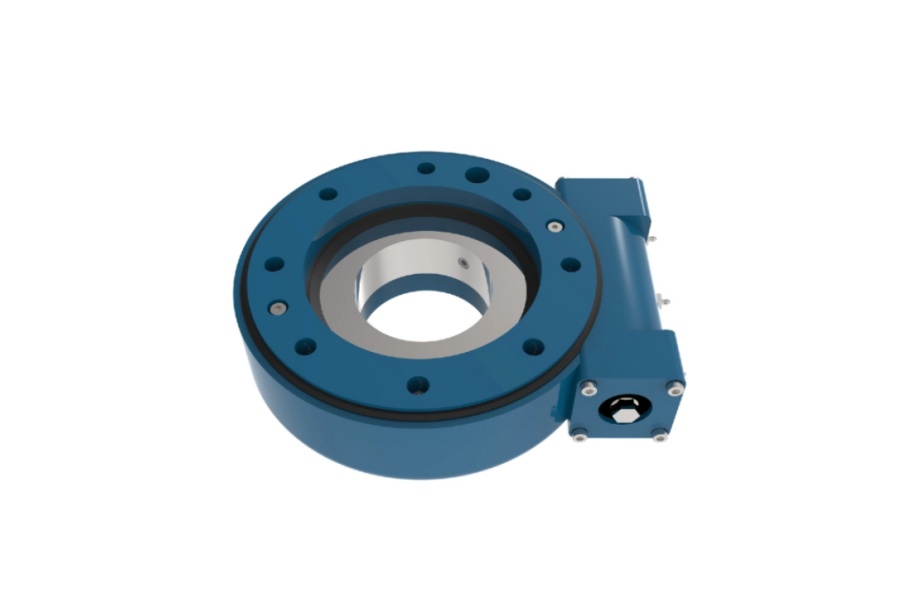

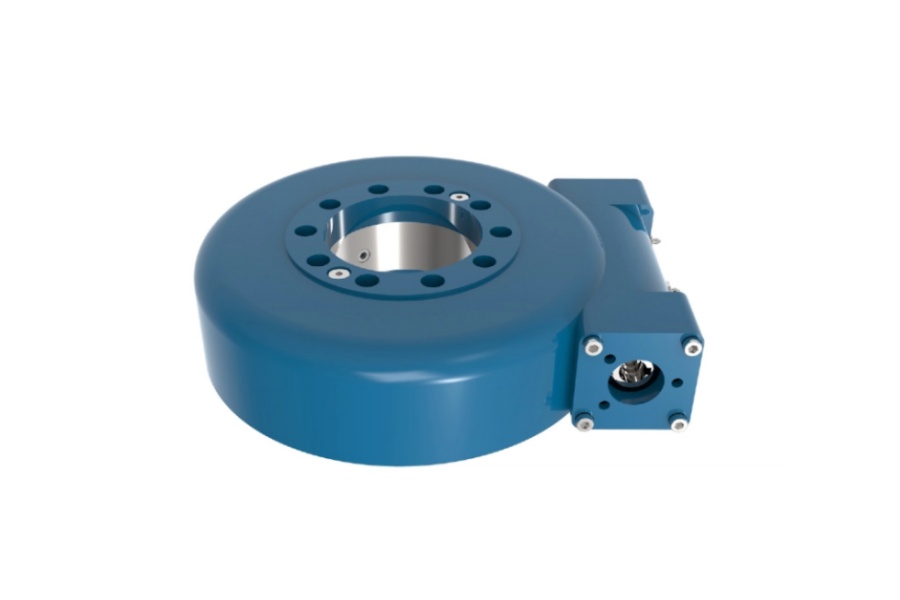

Conquer Crushing Loads: The Enveloping Slewing Drive SE7 - Heavy-Duty Dominance Redefined

What is the Enveloping Slewing Drive SE7?

The Enveloping Slewing Drive SE7 represents the pinnacle of heavy-duty slewing drive technology, defined by its superior enveloping worm gear system. In this design, the worm gear meticulously wraps around a significant portion of the worm wheel's circumference. This intricate geometry creates an exceptionally large contact area between the meshing teeth, far exceeding that of standard or even single-enveloping drives. The result is a monumental leap in torque transmission, optimized load distribution eliminating stress concentrations, exceptional rigidity that minimizes deflection under colossal loads, and smoother operation despite the immense forces involved. The SE7 is purpose-built for applications where standard drives buckle, handling astronomical axial, radial, and moment loads within a design optimized for ultimate strength and longevity. It is the cornerstone of reliability in extreme conditions.

The Indispensable Slewing Drive for Ship Crane Performance

Ship cranes operate in one of the most demanding environments on Earth: constant corrosive salt spray, relentless vibration, high dynamic loads during lifting and vessel motion, and the critical need for unwavering reliability far from shore. The Enveloping Slewing Drive SE7 is engineered specifically to conquer these challenges. Its massive torque capacity effortlessly handles the slewing of heavy loads, even with extended booms creating significant moment forces. The enveloping design's inherent rigidity ensures precise positioning and control of the load, crucial for safe and efficient operations on a rolling deck. Furthermore, the SE7's robust construction and advanced sealing (discussed next) provide the essential defense against saltwater corrosion and ingress, making it the trusted rotational heart for knuckle boom cranes, deck cranes, and offshore pedestal cranes where downtime is catastrophic.

Heavy-Duty by Design: The Core of the SE7

The "Heavy-Duty" designation of the Enveloping Slewing Drive SE7 is not marketing hyperbole; it's engineered into every component. This drive is fundamentally constructed for maximum load-bearing capability and structural integrity. Key elements include massive, high-grade alloy steel forgings for gears and critical components, subjected to specialized heat treatment processes (like carburizing and hardening) to achieve supreme surface hardness and core toughness. The slewing ring bearing at its core features large-diameter rolling elements (balls or rollers), often in a multi-row configuration, and robust raceways designed to withstand the crushing combination of axial, radial, and moment loads simultaneously. The housing is engineered for maximum stiffness, minimizing flex under load to maintain gear alignment and precision. Every aspect, from bolt sizes to seal labyrinths, is scaled and reinforced to meet the extraordinary demands of heavy industrial, maritime, and energy applications.

Defying the Elements: SE7 Slewing Drive Waterproof Rating

Operating reliably in wet, corrosive, or submerged conditions is paramount for drives like the SE7, especially in marine, offshore, and harsh industrial settings. LYRADRIVE equips the Enveloping Slewing Drive SE7 with a comprehensive sealing system designed to achieve high levels of environmental protection. While specific ratings depend on the exact configuration and sealing options chosen, the SE7 series is typically engineered to meet or exceed IP66 or IP67 ratings as standard for critical applications. IP66 offers powerful water jet protection, while IP67 guarantees temporary immersion protection (up to 1m for 30 minutes). For even more extreme environments, such as permanent partial submersion or high-pressure wash downs, options like enhanced lip seals, specialized exclusion seals, and even pressurized grease purge systems can be specified to achieve higher ingress protection (potentially IP68/IP69K). This robust sealing safeguards internal components from saltwater, dust, abrasive particles, and chemicals, ensuring longevity and reliable performance where lesser drives would rapidly fail.

Commanding Features of the Enveloping Slewing Drive SE7

The Enveloping Slewing Drive SE7 boasts an arsenal of features engineered for dominance in the most severe operating conditions. Its defining enveloping worm gear set delivers unparalleled torque density and crushing load capacity across all axes (axial, radial, moment). Extreme rigidity is inherent, minimizing deflection to maintain precision even under maximum stress. Constructed from premium, hardened alloy steels and featuring massive bearings, the SE7 offers exceptional durability and an extended service life under continuous heavy use. Precision manufacturing ensures minimal backlash for accurate positioning critical in load handling. A multi-stage, high-integrity sealing system provides superior protection against water, dust, and corrosion (typically IP66/IP67+, configurable higher). The worm gear design offers inherent self-locking for safety, preventing unintended back-driving under load. High efficiency variants minimize power loss. Multiple heavy-duty mounting configurations provide flexible integration. Crucially, LYRADRIVE offers extensive customization for the SE7, including specific flange designs, oversized shafts, special coatings (e.g., marine-grade), custom gear ratios, enhanced sealing packages, and specialized lubrication for extreme temperatures.

Where the SE7 Reigns Supreme: Demanding Applications

The Enveloping Slewing Drive SE7 is the cornerstone of reliability and power in applications where standard drives are simply inadequate. Heavy Marine & Offshore applications rely on it for ship and offshore crane slewing, robust deck machinery, and stern roller systems. Port Handling sees it powering the slewing mechanisms of massive container gantry cranes, heavy-duty mobile harbor cranes, and bulk material handling stackers/reclaimers. In Heavy Construction & Mining, it drives large excavator attachments, heavy-duty drilling rig rotation, and the slewing bases of colossal mining shovels and drag lines. The Renewable Energy sector utilizes SE7 drives for critical yaw systems on multi-megawatt offshore wind turbines and the demanding pitch control mechanisms of large blades. Industrial Heavy Lifting applications include heavy-duty turntables, large manipulators, and specialized lifting frames requiring extreme load capacity. Defense applications leverage its strength and reliability in artillery systems and heavy vehicle turrets. Essentially, any application demanding maximum torque, minimal deflection, and unwavering reliability under colossal loads and harsh environments is the natural domain of the SE7.

Factors Dictating Enveloping Slewing Drive SE7 Pricing

The investment in an Enveloping Slewing Drive SE7 reflects its heavy-duty engineering and capabilities, with pricing influenced by several critical factors. The sheer size and torque/load rating of the specific SE7 model is paramount; larger drives built for higher capacities require significantly more material and complex manufacturing, driving up cost. Material selection is crucial; the use of high-performance alloy steels, specialized hardening treatments, and corrosion-resistant coatings adds expense. The level of customization dramatically impacts price; standard configurations are baseline, while custom flanges, unique shaft sizes/outputs, application-specific gear ratios, or special surface treatments (like galvanizing or specialized paints) incur additional engineering and production costs. Bearing specifications within the massive slewing ring are a major factor; higher precision grades, specialized rolling elements, enhanced sealing on the bearing itself, and larger bearing diameters increase cost. The complexity of the sealing system, especially for high IP ratings (IP68/IP69K) or specialized environmental protection, adds cost. Gear manufacturing precision for the large, complex enveloping worm profile requires advanced, time-consuming machining and stringent quality control. Order volume can influence unit economics. Finally, global market dynamics, including raw material costs (especially specialty steels) and manufacturing overhead, also contribute to the final price of this industrial powerhouse.

Conclusion: The Uncompromising Powerhouse for Extreme Demands

The Enveloping Slewing Drive SE7 stands as a testament to engineering prowess, designed not just to perform, but to dominate in the most brutal operating environments. Its core enveloping worm technology delivers an unmatched combination of colossal torque, supreme rigidity, and astronomical load capacity that redefines the limits of slewing drive performance. Unlike drives that compromise, the SE7 is engineered from the ground up for heavy-duty supremacy, utilizing the finest materials, massive bearings, and robust construction. Its advanced sealing ensures resilience against water, corrosion, and contamination, making it the undisputed choice for critical marine, offshore, port, mining, and heavy industrial applications where failure carries immense cost. While factors like size, customization, materials, and bearing specs influence its price, the value proposition of the SE7 lies in its unparalleled ability to deliver reliable, powerful, and precise rotation under crushing loads for years on end. When the application demands nothing less than absolute strength and unwavering reliability, the Enveloping Slewing Drive SE7 from LYRADRIVE is the definitive engineered solution. It empowers industries to tackle their most formidable motion challenges with confidence.