Maintenance of Slew Drives in Construction Machinery

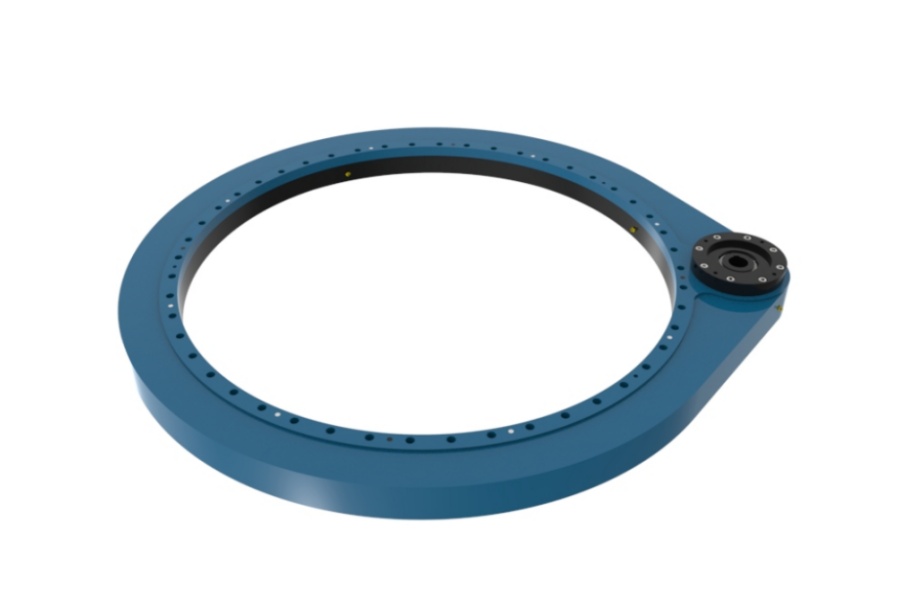

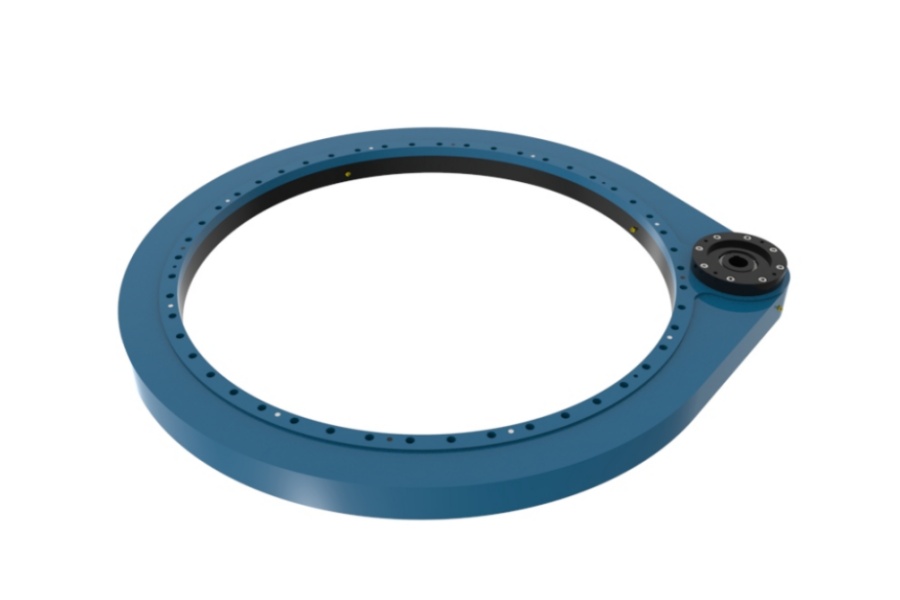

What is Slew Drive

Slew Drive is a fully integrated mechanical actuator system designed to provide controlled, high-torque rotational movement about a single axis. It represents a complete fusion of a robust drive motor (typically hydraulic or electric), a high-ratio speed reducer—most commonly a worm gearbox—and a large-diameter slewing ring bearing that features an integrated gear. This integrated design distinguishes it from systems where these components are sourced and assembled separately on the final machine. The primary function of a slew drive is to efficiently transform the high-speed, low-torque output of its input motor into a slow-speed, high-torque rotational output, enabling it to manage the immense loads encountered in construction equipment. This configuration simplifies machine architecture, saves space, and reduces the overall number of parts, making it a cornerstone component in heavy machinery where reliability under extreme stress, shock loads, and harsh environmental exposure is paramount.

Maintenance of Slew Drives in Construction Machinery

The rigorous operating environment of construction machinery—characterized by shock loads, vibration, exposure to abrasive dust, mud, moisture, and temperature extremes—makes a disciplined and proactive maintenance regimen for the slew drive not just recommended but absolutely essential for preventing costly downtime, ensuring operational safety, and maximizing the component's service life. Neglect in this area is the primary cause of premature failure, which can lead to catastrophic machine breakdowns on the job site.

The cornerstone of slew drive maintenance is a strict and disciplined lubrication schedule. The grease within the drive serves three critical functions: it reduces friction between the meshing gear teeth and rolling elements in the bearing raceways, it provides protection against corrosion, and it helps to purge contaminants that may have bypassed the seals. The interval for re-lubrication is not arbitrary; it is determined by the drive's operating hours, environmental conditions, and the manufacturer's specific recommendations. Under severe conditions of continuous operation or extreme dust/water exposure, lubrication may be required as frequently as every 100 hours, while less demanding applications may extend to 500 hours. It is crucial to use the exact type of grease specified by the manufacturer, typically a high-quality, extreme-pressure (EP) lithium complex grease with consistency grades (NLGI) suitable for the operating temperature range. The lubrication procedure must be performed correctly: clean the grease fittings thoroughly, rotate the drive during grease injection to ensure even distribution, and continue pumping until fresh, clean grease is seen purging from the seal lips, which indicates that old, potentially contaminated grease has been expelled.

A meticulous inspection routine is the second pillar of effective maintenance. This includes a visual and functional check of all seals before and after every use. Seals are the first line of defense against abrasive contaminants. Inspect them for cuts, tears, or signs of hardening and brittleness. Any compromised seal must be replaced immediately to prevent rapid internal wear. The mounting bolts must be checked for tightness according to the manufacturer's specified torque values and tightening sequence, typically following a star pattern. Loose bolts can lead to fretting, bolt failure, and catastrophic detachment of the drive. This check should be performed after the first 50-100 hours of operation and at regular intervals thereafter, as vibration can cause bolts to loosen over time. Furthermore, regularly monitor the drive's performance. Pay attention to any changes in its operation, such as increased effort required to turn (indicating higher friction), the emergence of unusual grinding, knocking, or whining noises (indicating wear or damage), and any noticeable increase in backlash or play (indicating wear in the gearing or internal components). Any such changes warrant immediate investigation.

Beyond daily and weekly checks, periodic professional inspection is vital. This involves a more thorough examination, potentially including checking gear tooth backlash with a dial indicator and measuring starting torque to quantify internal friction. For older drives or those operating in the most severe environments, a planned overhaul conducted by a certified technician may be necessary. This involves disassembly, thorough cleaning, inspection of all components for wear and damage, replacement of seals, bearings, and gears as needed, and reassembly with precise adjustments. Adhering to these structured maintenance steps—consistent lubrication, vigilant inspection, and timely professional service—will significantly extend the operational life of a slew drive, ensure the safety of the machinery, and provide a high return on investment by avoiding unplanned downtime and expensive emergency repairs.

Characteristics of Slew Drive

Slew Drives are defined by a distinct set of engineering characteristics that make them indispensable for high-torque, low-speed rotational applications in construction. Their most defining feature is the exceptionally high torque output delivered in a compact and integrated package. By combining a high-ratio speed reducer with a large-diameter slewing ring, they achieve massive mechanical advantage, allowing relatively small input motors to control and move immensely heavy loads with precision. This integrated design eliminates the need for custom-designed mounting solutions for separate components, simplifying machine design, saving space, and enhancing overall reliability.

A key operational characteristic of worm gear-based slew drives is their inherent self-locking capability. The design of the worm and worm wheel creates a high friction angle that prevents back-driving. This means that when the input drive stops, the load is immediately and reliably held in position without the need for an external braking system, a critical safety feature in applications like crane booms or excavator arms. Furthermore, slew drives are renowned for their robustness and durability. They are constructed from high-strength, hardened steel alloys (e.g., 42CrMo4) and are designed to operate reliably under severe conditions, including exposure to heavy shock loads, vibrations, and harsh environmental elements, thanks to their protective sealing systems.

Their design offers significant flexibility. They can be configured with the gear on the inner or outer ring, sourced with different sealing and lubrication options for various environments, and customized with a range of input motors (electric, hydraulic) and gear reduction ratios to meet the exact torque and speed requirements of a specific application. Whether using a worm gear for self-locking or a spur gear for higher efficiency, the slew drive provides a versatile and robust solution for powered rotation in the most demanding settings.

Applications of Slew Drive

The application of slew drives in construction and related heavy industries is fundamental to machine functionality. They are the core rotational mechanism in the upper structure of mobile cranes, enabling the 360-degree rotation of the boom for precise load placement. In excavators, they form the swing drive that allows the house to rotate independently of the tracks or wheels. They are equally critical in concrete pump trucks, where they provide the precise rotational control needed to position the lengthy delivery boom accurately.

Beyond these primary applications, slew drives are essential in a wide range of other earthmoving and lifting equipment. They are found in the rotating platforms of crawler cranes, all-terrain cranes, and rough-terrain cranes. They are integral to the operation of pile boring rigs and foundation drilling equipment, providing the torque needed to rotate augers and drilling heads. Furthermore, they are used in mining machinery, tunnel boring machines, and heavy-duty material handlers at ports and scrapyards. Their ability to provide reliable, high-torque rotation in a compact package makes them the preferred actuation solution wherever heavy loads need to be moved and positioned with control and precision.

Factors Influencing the Price of Slew Drive

The price of a slew drive is determined by a complex interplay of technical specifications, material choices, and commercial factors. The single largest cost driver is often the size, material, and design of the core slewing ring and gearing. Larger diameters require more raw material and more complex machining processes. The grade of steel (e.g., standard 50Mn or high-strength 42CrMo4) and the extent of heat treatment (induction hardening) applied to the raceways and gear teeth significantly impact cost. More robust designs, such as those using crossed rollers instead of balls for higher moment capacity, also increase the price.

The level of customization and complexity is another major determinant. A standard, catalogued unit is more economical than a fully custom-designed drive. Customizations such as special gear specifications (module, precision grade), unique mounting hole patterns, specific seal materials for extreme temperatures (e.g., Viton), special surface coatings (e.g., zinc plating for corrosion resistance), and integrated sensors for condition monitoring drastically increase manufacturing overhead. The specifications of the included components, namely the type and power of the input motor (standard electric motor vs. a customized hydraulic motor) and the design of the gear reducer, also form a significant portion of the total cost.

Performance requirements and quality assurance directly influence price. Drives manufactured to standard industrial tolerances are cost-effective. Those produced to ultra-precise tolerances for high-performance applications, which require 100% non-destructive testing (NDT), full material traceability with mill certificates, and extended performance validation, command a premium. Finally, order quantity and external factors play a role. Large volume orders benefit from economies of scale, reducing the unit cost. Global fluctuations in steel prices, international shipping costs, and import/export tariffs can also cause price variations, making the total landed cost a key consideration for procurement.

Supplier of Slew Drive

For engineers and procurement specialists in the construction industry seeking a reliable source for high-performance slew drives, LYRADRIVE stands as a manufacturer with deep expertise in the engineering and production of these critical systems. The company provides comprehensive technical support that includes guidance on proper selection, installation, and perhaps most importantly, the development of tailored maintenance schedules to ensure longevity and reliability in harsh operating environments. This application-focused support is backed by a rigorous quality management system that governs every production stage, from material selection and forging to precision machining, heat treatment, final assembly, and testing. By offering advanced manufacturing capabilities, engineering-led problem-solving, and a commitment to delivering robust and durable drive solutions, LYRADRIVE has established itself as a trusted partner for a global clientele across the construction, mining, and heavy equipment manufacturing industries.