Spur Gear Slew Drive Applications in Automated Industrial Machinery

What is Spur Gear Slew Drive

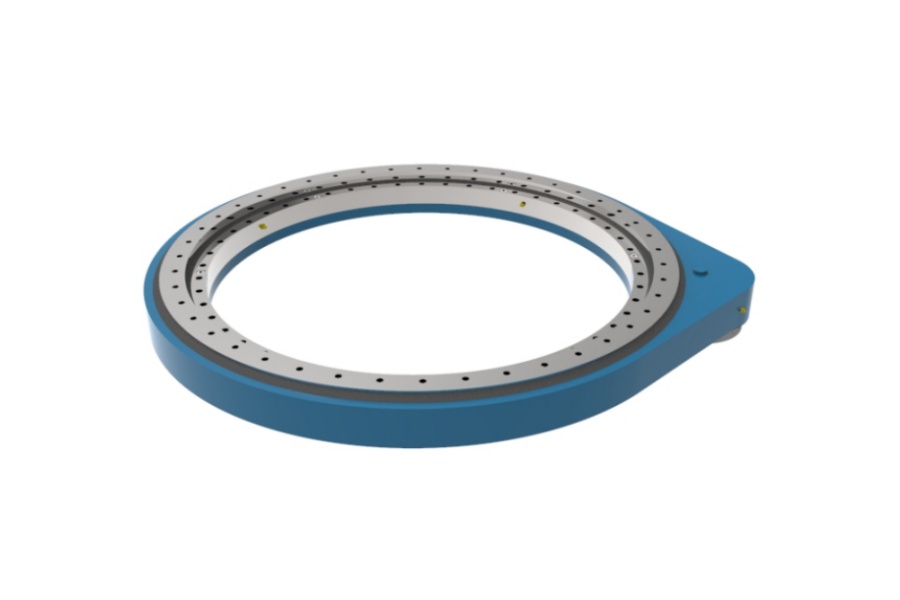

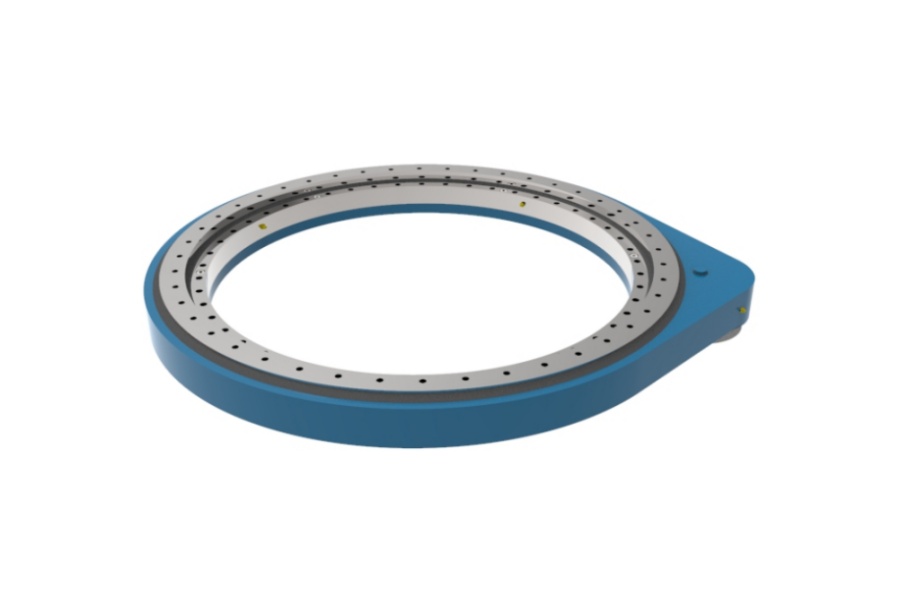

Spur Gear Slew Drive represents an integrated rotational system that combines a slewing bearing with a gear mechanism to facilitate precise rotational movement under significant load conditions. Unlike traditional separate component systems, Spur Gear Slew Drives incorporate all necessary elements including gears, bearings, and mounting interfaces into a single compact unit, providing exceptional structural integrity and operational efficiency. The variant specifically employs hardened precision gears rather than worm drives, enabling higher rotational speeds and improved efficiency while maintaining the compact form factor and load-handling capabilities that make Spur Gear Slew Drives indispensable in modern industrial applications. This integrated approach to rotational power transmission has revolutionized how engineers approach automation system design, particularly where space constraints, precision requirements, and reliability are paramount concerns.

Spur Gear Slew Drive Applications in Automated Industrial Machinery

The integration of Spur Gear Slew Drives has transformed automation capabilities across numerous industrial sectors, offering performance characteristics particularly suited to modern manufacturing environments where speed, precision, and reliability are essential requirements.

Spur Gear Slew Drives distinguish themselves from traditional worm drive systems through their ability to achieve significantly higher rotational speeds while maintaining precise positioning control. This capability makes them ideally suited for automated applications requiring rapid indexing or continuous rotation at operational speeds that would be unattainable with worm drive alternatives. The efficiency of gear systems reduces heat generation during operation, contributing to longer service life and reduced cooling requirements in thermally sensitive environments. These characteristics have led to widespread adoption in high-cycle automation equipment where both speed and precision are critical performance metrics.

Compared to standard slewing bearings, Spur Gear Slew Drives offer numerous advantages that justify their increasing preference in automated machinery design. The completely enclosed housing provides superior protection against environmental contaminants including dust, chips, and fluids commonly encountered in industrial settings. This integrated design eliminates the need for custom mounting solutions and protective enclosures that would otherwise be required with separate component systems. The pre-engineered nature of Spur Gear Slew Drives ensures optimal gear meshing and alignment under load, reducing maintenance requirements and eliminating the installation variables that can affect performance in field-assembled systems.

The manufacturing sector has particularly embraced Spur Gear Slew Drives in welding positioners, where their combination of high-speed capability and precise positioning enables optimal welding angles and significantly improved production rates. The enclosed design protects internal components from spatter and debris while the integrated sealing maintains lubrication integrity in challenging environments. Similarly, machine tool applications including rotary tables and indexing fixtures benefit from the rapid positioning and exceptional rigidity provided by Spur Gear Slew Drives, reducing non-cutting time and improving machining accuracy through minimal deflection under cutting loads.

Material handling automation represents another significant application area where Spur Gear Slew Drives excel. Automated guided vehicles (AGVs), robotic transfer units, and assembly positioners utilize these drives for precise load orientation and transfer operations. The compact design allows integration within space-constrained equipment profiles while providing the necessary torque and precision for smooth operation. Packaging machinery employs Spur Gear Slew Drives for container indexing, labeling positioning, and product orientation tasks where rapid, accurate rotation directly impacts production line efficiency.

The installation advantages of Spur Gear Slew Drives further contribute to their automation suitability. The completely self-contained design requires only mounting to a base structure and connection to the driven component, with the drive motor directly engaging the integrated input gear. This simplicity significantly reduces installation time and eliminates the alignment challenges associated with traditional drive systems. The standardized interface dimensions facilitate replacement and retrofitting operations, minimizing downtime during maintenance or upgrades—a critical consideration in automated manufacturing environments where production interruptions have substantial financial implications.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drives possess distinctive characteristics that make them indispensable for industrial automation applications. Their most significant feature is their integrated design philosophy, which combines multiple functional components into a single compact unit, providing substantial space savings and structural simplicity compared to traditional separate systems. These drives deliver exceptional load-handling capability, simultaneously managing complex load combinations including axial forces, radial loads, and moment loads through robust construction and precision-engineered components. The variants specifically offer higher efficiency and operational speeds compared to worm drive alternatives, enabling faster cycle times in automated applications. Precision positioning capability represents another critical characteristic, with many systems achieving positioning accuracy within arc-minute ranges through precision gearing and minimal backlash design. Durability is enhanced through the use of high-strength alloy steels, advanced heat treatment processes, and comprehensive sealing systems that ensure reliable performance in demanding industrial environments. The modular design approach facilitates easier installation and maintenance, with standardized mounting interfaces and accessible service points that simplify integration and upkeep while reducing total cost of ownership.

Applications of Spur Gear Slew Drive

The unique combination of strength, precision, and compactness enables Spur Gear Slew Drives to serve critical functions across numerous industrial sectors and applications. In renewable energy applications, they form the core component of solar tracking systems, precisely orienting photovoltaic panels to maximize energy capture throughout the day, while also serving in wind turbines for pitch and yaw control mechanisms that optimize performance and protect against extreme weather conditions. Construction equipment extensively utilizes Spur Gear Slew Drives in excavators, cranes, and aerial work platforms, where they provide the rotational capability for booms, platforms, and lifting mechanisms that require smooth operation under variable loads. Material handling equipment incorporates these drives in rotary conveyors, stackers, and manipulators that require controlled rotation with precise positioning capabilities. Industrial automation systems employ Spur Gear Slew Drives in robotic welding cells, indexing tables, and automated assembly lines where accurate rotational positioning is essential for manufacturing precision. The aerospace and defense sectors utilize them in radar systems, satellite communication antennas, and weapon platforms that require accurate positioning and stability under demanding operational conditions. Even medical equipment manufacturers incorporate precision Spur Gear Slew Drives in advanced imaging systems like CT and MRI scanners where smooth, reliable rotation is critical for diagnostic accuracy. Additional applications include mining equipment, marine deck machinery, agricultural implements, and telescope positioning systems, demonstrating the remarkable versatility of these components across virtually every sector requiring controlled rotational movement under load.

Factors Influencing the Price of Spur Gear Slew Drive

The cost structure of Spur Gear Slew Drives is determined by numerous technical and commercial factors that reflect their engineering complexity and performance capabilities. The primary cost driver is the physical size and load capacity rating, with larger units designed for higher loads commanding significantly higher prices due to increased material requirements, more complex manufacturing processes, and enhanced quality control measures. The selection of materials represents another significant factor, with high-grade alloy steels, specialized coatings, and advanced heat treatment processes adding substantial value while increasing manufacturing expenses related to material procurement and processing. Manufacturing precision constitutes a major cost component, as precision-ground gear teeth, honed bearing surfaces, and exacting tolerance control require advanced machinery, skilled labor, and extensive quality verification procedures, all contributing to higher production costs. The type and complexity of the drive mechanism influence price, with systems generally commanding premium pricing compared to worm drives due to their higher efficiency and speed capabilities, while planetary or hybrid systems offering special features further increase costs. Additional features such as integrated motors, brakes, sensors, or special sealing systems designed for extreme environments add functionality but also increase the overall cost through additional components and assembly complexity. Certification requirements including ISO standards, industry-specific qualifications, and third-party verification processes contribute to the total cost through testing and documentation expenses. Finally, brand reputation, warranty coverage, after-sales support services, and order volume considerations contribute to the total cost of ownership, with established manufacturers typically commanding premium prices based on proven reliability and comprehensive technical support offerings.

Supplier of Spur Gear Slew Drive

LYRADRIVE represents a leading manufacturer and global supplier of high-performance Spur Gear Slew Drive solutions, offering comprehensive rotational drive systems that meet rigorous application requirements across various industries. The company maintains an unwavering commitment to quality through advanced manufacturing processes, stringent quality control measures, and continuous product development initiatives. Their product portfolio encompasses both standard and customized solutions designed to address specific load capacity, environmental condition, and integration requirements, supported by extensive technical expertise and engineering consultation services. LYRADRIVE's Spur Gear Slew Drives particularly reflect their innovation focus, delivering the speed and precision required by modern automated machinery while maintaining the robustness expected in industrial environments. By focusing on reliability, performance, and customer satisfaction, LYRADRIVE has established itself as a trusted partner for businesses that depend on precision rotational drive technology, offering competitive solutions that balance performance characteristics with total cost of ownership considerations.