Mastering Power Transmission: The Ultimate Guide to WE7 Worm Gear Technology

What is Worm Gear Transmission WE7?

A WE7 worm gear drive is a specific type of mechanical reducer utilizing a unique screw-like component (the worm) engaging with a specially designed gear (the worm wheel or gear). The worm, typically the input driver, meshes with the teeth on the periphery of the worm wheel, which is the output element. This configuration inherently produces motion at a right angle (90 degrees) between the input and output shafts. The "WE7" designation refers to a standardized size and mounting configuration within a manufacturer's product line, signifying specific dimensions, power capacities, and mounting interfaces. The key principle lies in the sliding contact between the worm and wheel teeth, allowing for significant speed reduction ratios in a single stage, often achieving high torque output from a relatively compact package. This design also frequently provides a self-locking feature, preventing back-driving under certain conditions.

WE7 Worm Gear Reducer: Parameters Deep Dive & Your Selection Guide

Selecting the optimal WE7 reducer requires careful consideration of several critical parameters. First, determine the Input Power (kW/HP) and Input Speed (RPM) of your motor or drive source. This directly influences the unit's thermal capacity and longevity. Next, identify the required Output Torque (Nm/lb-ft) needed to drive your load under all operating conditions, including peak loads. The Reduction Ratio (i) is crucial; WE7 reducers typically offer ratios ranging from approximately 5:1 up to 100:1 or even higher in a single stage. This ratio defines the relationship between input speed and output speed (Output Speed = Input Speed / Ratio). Efficiency (%) varies significantly with ratio and load; higher ratios generally have lower efficiency due to increased sliding friction. Mounting Position (foot-mounted, flange-mounted - B5, B14, input shaft mounted) dictates how the reducer integrates into your machine. Lubrication type (oil bath, synthetic grease) and Service Factor (SF) – a multiplier applied to the required torque to account for load characteristics (shock loads, starts/stops, duty cycle) – are vital for durability. Finally, consider Environmental Factors like operating temperature range, ingress protection (IP rating) needed against dust and moisture, and potential exposure to chemicals. Matching these parameters precisely to your application ensures reliable performance and maximum lifespan.

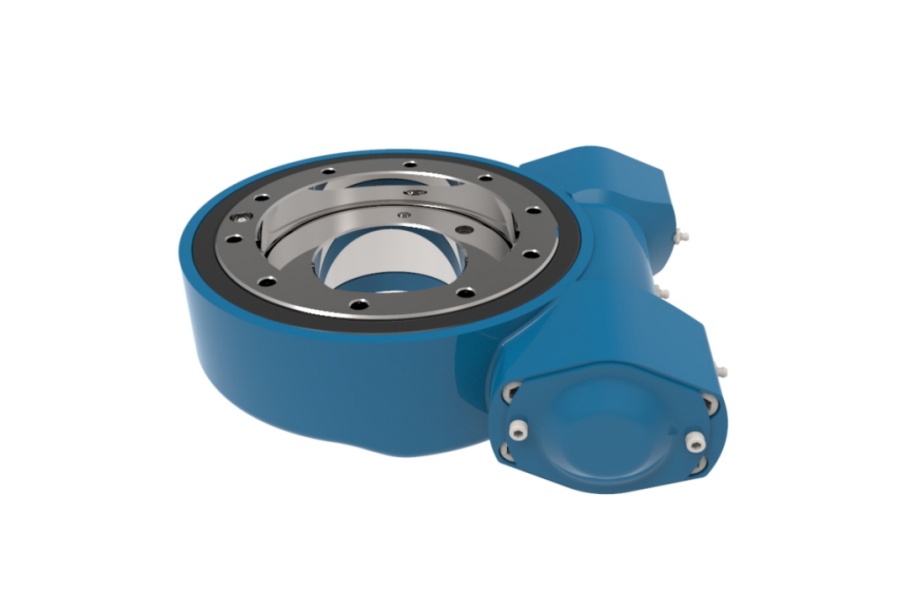

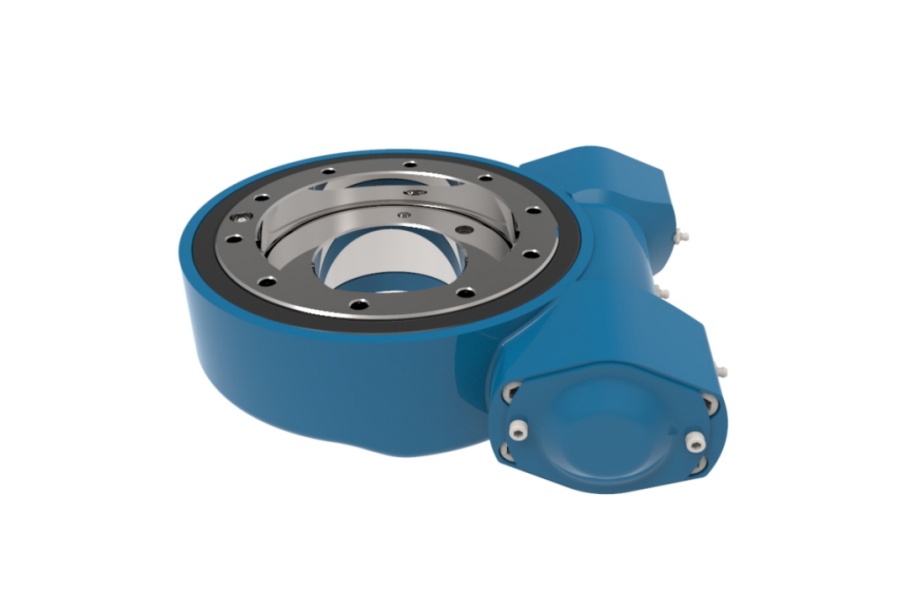

The Power of Compact Design: WE7 Hollow Shaft Reducers

A significant variant within the WE7 series is the hollow shaft configuration. Instead of a traditional solid output shaft, this design features a hollow bore through the center of the output worm wheel. This bore allows the driven machine's shaft (like a conveyor roller shaft, mixer agitator shaft, or packaging line drive shaft) to pass directly through the reducer. This offers immense advantages: Simplified Installation and Alignment - mounting components directly onto the driven shaft becomes easier without needing couplings. Space Optimization - eliminates the need for coupling guards and reduces overall drive package length, crucial in tight spaces. Reduced Maintenance - fewer components (like couplings and associated bearings) mean fewer potential failure points. Improved Torque Transmission - direct connection minimizes losses and backlash associated with couplings. Enhanced Safety - the integrated design can be inherently safer by enclosing rotating components. WE7 hollow shaft reducers often use a robust locking device (like a locking collar or taper bush system) inserted into the hollow bore to securely grip the driven shaft, transmitting torque efficiently without slippage. They are particularly favored in material handling, conveyor systems, and applications demanding a clean, integrated drive solution.

Unlocking the Advantages: Key Features of WE7 Worm Gear Drives

WE7 worm gear drives stand out due to a compelling combination of inherent worm gear characteristics and design optimizations. Compact Right-Angle Design: Their ability to achieve significant speed reduction at 90 degrees in a single, space-efficient stage is a primary advantage over other gear types often requiring multiple stages. High Single-Stage Ratios: Delivering substantial speed reduction and torque multiplication in one compact unit simplifies drivetrain design. Smooth and Quiet Operation: The sliding meshing action, when properly lubricated and manufactured, results in inherently quieter operation compared to some spur or helical gears, especially at lower speeds. Shock Load Tolerance: The tooth engagement design offers good resistance to impact and shock loading, protecting both the reducer and the driven equipment. Self-Locking Capability (Potential): While not absolute and dependent on the lead angle and friction, many WE7 configurations exhibit a high resistance to back-driving (where the output shaft drives the input). This is invaluable for applications like hoists, lifts, and conveyors needing to hold position without an external brake. Versatility: Available in solid shaft, hollow shaft, and various mounting orientations (foot, flange), they adapt to diverse mechanical layouts. Cost-Effectiveness: Generally offering a lower initial cost per unit of torque compared to many other right-angle gear solutions, especially for lower to medium power ranges.

Where Efficiency Meets Angle: Diverse WE7 Worm Gear Applications

The unique blend of features makes WE7 worm gear reducers ubiquitous across industrial and commercial sectors. Material Handling: Conveyors of all types (belt, roller, chain), palletizers, stackers, and sorting systems rely on their torque, compactness, and potential self-locking. Packaging Machinery: Filling machines, capping machines, labeling systems, and cartoners benefit from their smooth motion and right-angle power transfer. Food & Beverage Processing: Mixers, agitators, dough handling, bottling lines, and conveyor drives utilize their reliability and often stainless steel options. Construction Equipment: Cement mixers, small hoists, winches, and screed drives leverage their torque and shock resistance. Automated Gates & Doors: Operators for industrial doors, barriers, and garage doors depend on their self-locking ability and compact power. HVAC Systems: Large damper actuators, fan drives, and pump drives utilize their right-angle configuration. Agricultural Machinery: Feed conveyors, mixers, and small processing equipment benefit from their durability. Stage & Theatre: Rigging systems for moving lights, scenery, and curtains often use them for controlled movement. General Industrial Automation: Any application needing reliable, compact speed reduction at a right angle is a potential candidate for a WE7 drive.

Investing Wisely: Factors Influencing WE7 Worm Gear Drive Pricing

The cost of a WE7 worm gear reducer is not a single figure; it fluctuates based on several key factors. Material Specifications: The base housing material (cast iron vs. aluminum) and the gear materials (bronze wheel vs. hardened steel worm vs. specialized alloys) significantly impact cost. Higher strength, wear resistance, and corrosion resistance come at a premium. Size & Power Rating: Larger frame sizes (WE7 itself denotes a size range, but variations exist) designed for higher input power and output torque command higher prices. Reduction Ratio: While the ratio itself isn't always a direct linear cost driver, achieving very high ratios (e.g., >60:1) within the WE7 frame might involve design nuances affecting cost. Complex or custom ratios also add expense. Hollow Shaft vs. Solid Shaft: Hollow shaft configurations typically cost more than equivalent solid shaft models due to the complexity of the hollow bore and the locking mechanism. Mounting Configuration: Standard foot mounts are generally the most economical. Flange mounts (B5, B14) or input shaft mounting options add complexity and cost. Efficiency Class & Backlash Requirements: Units engineered for higher efficiency (often involving precision manufacturing and premium materials) or requiring very low backlash for positioning accuracy will be more expensive. IP Protection Rating: Higher ingress protection ratings (IP65, IP66) against dust and water require enhanced sealing solutions, increasing cost. Brand Reputation & Quality: Established manufacturers with rigorous quality control, advanced manufacturing techniques, and proven reliability typically command higher prices than generic alternatives. Customization: Any deviation from standard catalog specifications (special shaft dimensions, coatings, lubrication, sensors) adds cost. Order Volume: Larger quantities often benefit from economies of scale, reducing the unit price.

Supplier of WE7 Worm Gear

Selecting the right supplier for your WE7 worm gear drives is as critical as selecting the right technical specifications. Look for partners with proven expertise and a commitment to quality. LYRADRIVE stands as a prominent and reliable provider in this field. They offer comprehensive WE7 product lines, encompassing both standard catalog units and the flexibility for custom-engineered solutions tailored to specific application demands. Quality Manufacturing is paramount; LYRADRIVE utilizes robust materials and adheres to stringent production and quality control processes, ensuring durability, performance consistency, and long service life. Beyond just supplying the reducer, technical support is essential. A strong supplier provides expert assistance with selection, sizing calculations, application engineering, and integration advice. Global availability and reliable logistics ensure you receive the components you need, when and where you need them. Inventory breadth covering various ratios, configurations (solid/hollow shaft, mounting styles), and accessories minimizes lead times. Finally, assess the supplier's reputation for after-sales service, including warranty support, spare parts availability, and maintenance guidance. Partnering with a supplier like LYRADRIVE, known for engineering excellence and customer focus, translates to optimized machine performance, reduced downtime, and a strong return on investment. Request your WE7 quote or technical consultation today to power your next project.