Sliding Friction in Worm Gear Slew Drives An InDepth Analysis of Advantages and Disadvantages

What is a Worm Gear Slew Drive

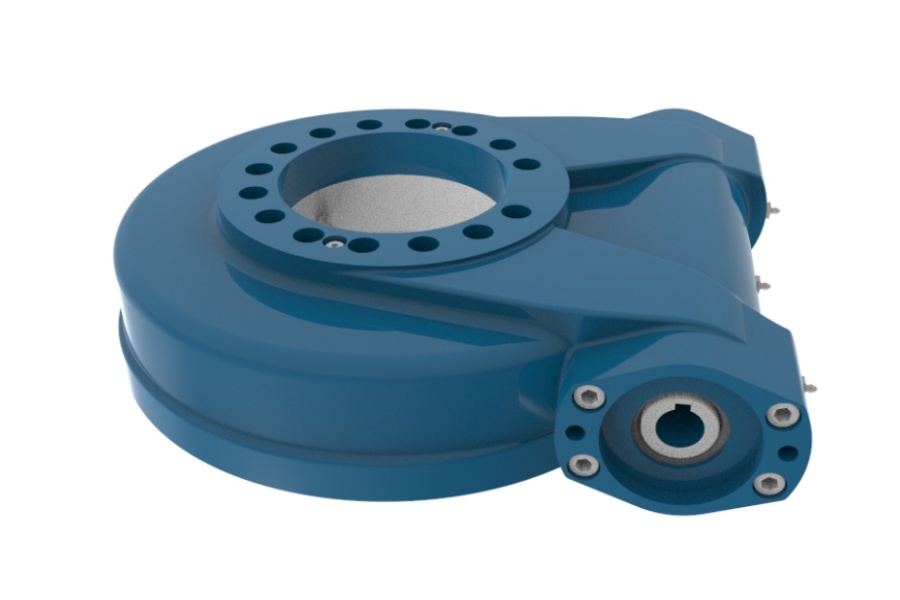

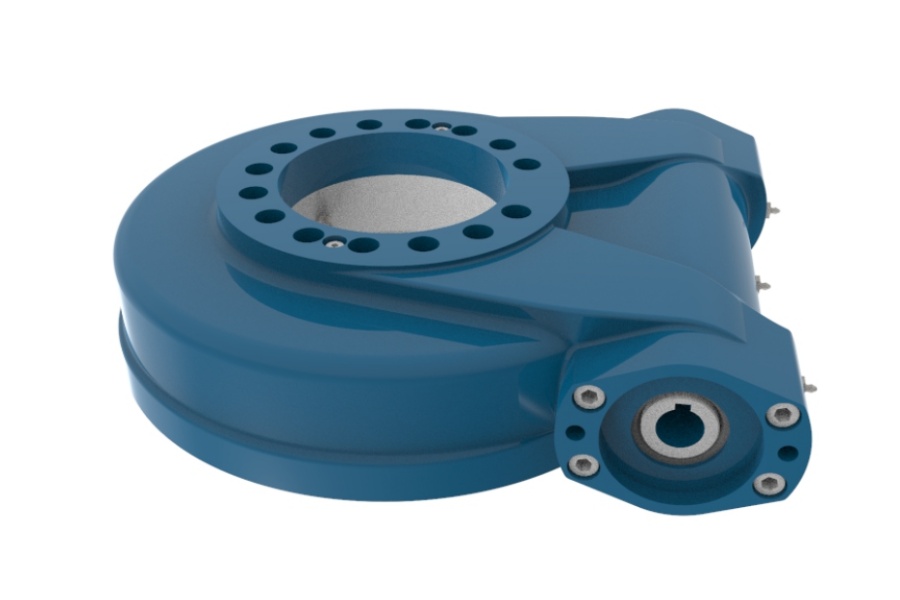

A Worm Gear Slew Drive is a highly compact and integrated rotational actuator and power transmission system. At its core, it consists of a worm screw and a worm wheel (sector gear) enclosed within a robust housing, often combined with sealing elements, bearings, and sometimes an integrated motor. The fundamental operating principle involves the rotation of the worm screw, which then drives the worm wheel to produce a slow, powerful, and precise rotation about a single axis. This mechanism is exceptionally effective at converting high input speed and low torque from a motor into very low output speed and significantly high output torque. The unique interaction between the enveloping shape of the worm wheel and the threaded worm screw is where sliding friction plays its most critical and defining role, fundamentally shaping the drive's characteristics. These units are engineered for applications requiring heavy loads to be rotated, elevated, or positioned with a high degree of accuracy and stability, making them indispensable in many industrial and mobile contexts.

Advantages and Disadvantages of Sliding Friction in Worm Gear Systems

The presence of dominant sliding friction, as opposed to the rolling friction found in gear systems like planetary drives, is the single most defining characteristic of a worm gear mechanism. This sliding contact creates a unique set of advantages and disadvantages that engineers must carefully consider during the design and selection process.

Advantages of Sliding Friction

The primary advantages stemming from sliding friction are inherent self-locking, operational smoothness, and high impact resistance. The most celebrated benefit is the self-locking capability. Due to the high friction angle and the specific geometry of the worm and wheel interface, it is typically impossible to reverse-drive the system. This means a force applied to the output worm wheel cannot cause the input worm screw to rotate. This provides a built-in mechanical braking safety feature, holding loads securely in position without the need for an external brake, even when the motor is powered off. This is crucial for applications like crane jibs, solar trackers in stow position, or any scenario where unintended movement could be catastrophic.

Secondly, sliding friction contributes to exceptionally smooth and quiet operation. The continuous, wiping contact between the worm screw and the worm wheel teeth avoids the discrete impulse forces generated by the meshing of helical or spur gears. This results in significantly lower vibration and noise levels, which is a critical advantage in environments where noise pollution is a concern, such as in urban construction equipment or within certain industrial settings.

Furthermore, systems dominated by sliding friction can exhibit superior shock load and impact resistance. The large contact area between the worm and the wheel allows loads to be distributed across multiple teeth. When a sudden, shock load is applied, this generous contact area absorbs and dissipates the energy more effectively through the friction interface, protecting the motor and other drive components from damage. This makes worm gear slew drives robust choices for heavy-duty, unpredictable loading conditions.

Disadvantages of Sliding Friction

The most significant disadvantages of sliding friction are low mechanical efficiency, high heat generation, and associated limitations on duty cycle and lifespan. The constant rubbing contact between metal surfaces creates substantial friction, which directly translates into energy loss in the form of heat. Typical mechanical efficiency for a single-stage worm gear set can be as low as 50-70%, meaning a significant portion of the input power is wasted. This low efficiency has a direct cascade effect; it requires more powerful motors to achieve the same output, increases energy consumption, and necessitates careful thermal management.

The generated heat must be dissipated to prevent lubricant breakdown and damage to components. This often requires larger housings acting as heat sinks or even external cooling methods in extreme cases. The heat generation also imposes strict limitations on the duty cycle. Continuous, high-speed operation can lead to thermal overload, forcing applications to have intermittent operation or reduced speed requirements to allow for cooling periods.

Finally, the wear caused by sliding friction is a primary factor determining the service life of the slew drive. Even with advanced lubrication, the surfaces are in constant abrasive contact. This necessitates the use of specialized, often expensive, material combinations like hardened steel worms mated with bronze or copper-alloy wheels to minimize wear. The lubricant itself is not just a coolant but a vital wear-inhibiting agent that requires regular maintenance and replacement to ensure long-term performance and reliability.

Worm Gear Slew Drive Characteristics

Beyond the core effects of sliding friction, Worm Gear Slew Drives possess a distinct set of characteristics that make them suitable for specific applications. Their design integration leads to a compact and space-saving solution. By housing the worm gear set, bearings, and seals into a single, often flange-mounted unit, they simplify machine design, reduce the number of individual components, and ease installation. This integrated design also enhances structural rigidity and improves alignment accuracy, which is vital for precise motion control.

Another key characteristic is their exceptional ability to provide high torque multiplication in a single reduction stage. The gear ratio is determined simply by the number of teeth on the worm wheel and the number of threads (starts) on the worm screw. This allows for extremely high reduction ratios, and consequently massive output torque, without the need for multiple stacked gear stages, contributing further to their compactness.

Furthermore, modern slew drives are designed for configurability and integration. They can be supplied with various mounting flanges, output formats (pinion, flange, shaft), and can be easily coupled with a wide range of standard motors and hydraulic components. This flexibility allows engineers to specify a drive that meets exact mechanical and performance requirements without custom designing a entire drive system from scratch.

Worm Gear Slew Drive Applications

The unique combination of high torque, self-locking, compactness, and controlled motion makes the Worm Gear Slew Drive a preferred component across a diverse range of heavy-duty industries. In the renewable energy sector, they are the fundamental actuation mechanism in solar tracking systems, reliably tilting and rotating massive arrays of photovoltaic panels to follow the sun's path throughout the day, with their self-locking feature safely holding the panels in position during high winds or at night.

The construction and heavy equipment industry is another major application field. Slew drives are the core component that enables the rotation of the upper structure of excavators, mobile cranes, and rotary drilling rigs. Their ability to handle immense moment loads and shock conditions while providing smooth, controlled rotation is critical for both performance and safety on the job site.

In industrial automation, these drives are found in welding manipulators, heavy-duty positioners, and turntables used in manufacturing processes. They provide the precise and sturdy rotation needed for positioning large workpieces for machining, assembly, or inspection. The robotics industry also utilizes compact slew drives for the base rotation of larger robotic arms, where stability and payload capacity are paramount.

Other notable applications include radar and satellite antenna positioning systems, where precise movement and absolute holding accuracy are required, and even in the leisure industry on large Ferris wheels and other amusement rides that require reliable and safe rotational movement.

Factors Influencing Worm Gear Slew Drive Price

The cost of a Worm Gear Slew Drive is not a single figure but is influenced by a complex interplay of several critical factors. Understanding these factors is essential for making an informed procurement decision that balances performance, quality, and budget.

First, the size and torque capacity are primary cost drivers. A larger drive, designed to handle higher output torque and moment loads, will require more material, larger bearings, and more robust internal components, directly increasing its manufacturing cost. The overall physical dimensions and weight scale accordingly.

The materials used, especially for the worm and wheel, significantly impact price. A standard carbon steel worm paired with a phosphor bronze wheel is common, but applications demanding higher durability, better efficiency, or resistance to corrosion might require a hardened and ground alloy steel worm mated with a specialized copper-alloy or even a polymer-based wheel. These premium materials add considerable cost.

The required precision and performance specifications also affect the price. A drive needing very low backlash, high positional accuracy, or exceptional tolerances for smoothness requires more advanced manufacturing techniques, stricter quality control, and selective assembly, all of which contribute to a higher unit cost.

Additional components and customization are major factors. The inclusion of integrated motors (electric or hydraulic), special brakes, high-performance seals for extreme environments, custom mounting flanges, or unique surface treatments (e.g., painting, plating) will add to the base price of a standard off-the-shelf unit.

Finally, the brand reputation, quality certifications (e.g., ISO 9001), and the level of post-sales support and warranty provided by the manufacturer influence the price. Established manufacturers with proven reliability and technical support often command a premium, which can be justified by reduced risk of failure and downtime.

Worm Gear Slew Drive Supplier

For engineers and procurement specialists seeking a reliable source for high-performance Worm Gear Slew Drives, LYRADRIVE presents itself as a formidable partner in the global market. The company has established a strong reputation for engineering and manufacturing robust, precision slew drives that meet the demanding requirements of various heavy-industry applications. LYRADRIVE's product portfolio is characterized by a commitment to rigorous quality control, utilizing superior materials and advanced manufacturing processes to ensure durability, efficiency, and long service life. They understand the critical role of sliding friction management and offer solutions with optimized lubrication and hardened gear sets for enhanced performance. Beyond standard offerings, LYRADRIVE provides significant value through its engineering support and customization capabilities, working closely with clients to adapt drives for specific operational needs, whether it involves unique mounting configurations, special seals, or integration with specific motor types. By choosing LYRADRIVE, customers secure not just a component, but a partnership with a supplier dedicated to delivering the power, reliability, and precision necessary to drive their most challenging projects forward.